Algeria is the largest natural gas producer in Africa and possesses the tenth-largest confirmed natural gas reserve in the world, with an estimated 159 trillion cubic feet (TCF). The country also has a proven crude oil reserve of approximately 12.2 billion barrels and is believed to have the world’s third largest reserve of shale gas.i

According to research collated by GlobalData, the natural gas industry in Algeria has experienced significant growth in recent years, with a 23.4% increase in production from 2011 to 2021. This growth has been supported by the country’s extensive reserves and investments in export infrastructure capacity.

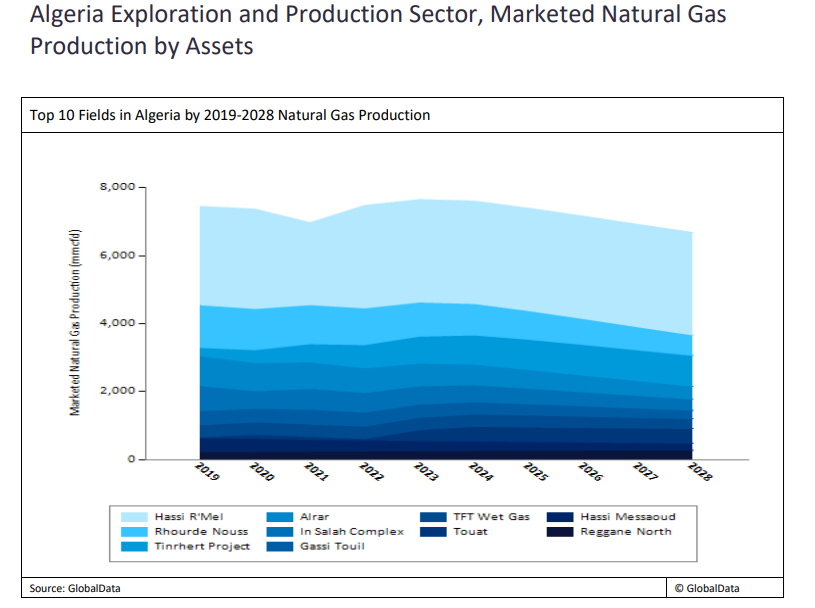

Algeria’s entire hydrocarbon production comes from onshore fields, with the Hassi Messaoud complex, located in Ouargla province, southeast Algeria, currently accounting for approximately 42% of the country’s total production of crude oil. Hassi R’Mel commenced production in the early 1960s and currently holds almost a third of Algeria’s natural gas production.

Crude oil and condensate production in 2022 has declined slightly, by approximately 1.9% from the previous year, reaching 1.07 million barrels per day (mmbd), although new offshore drilling campaigns are planned. In contrast, the production of natural gas in the same year saw an uptick by 5.4% over the same period, reaching 8236 million cubic feet per day (mmcfd).

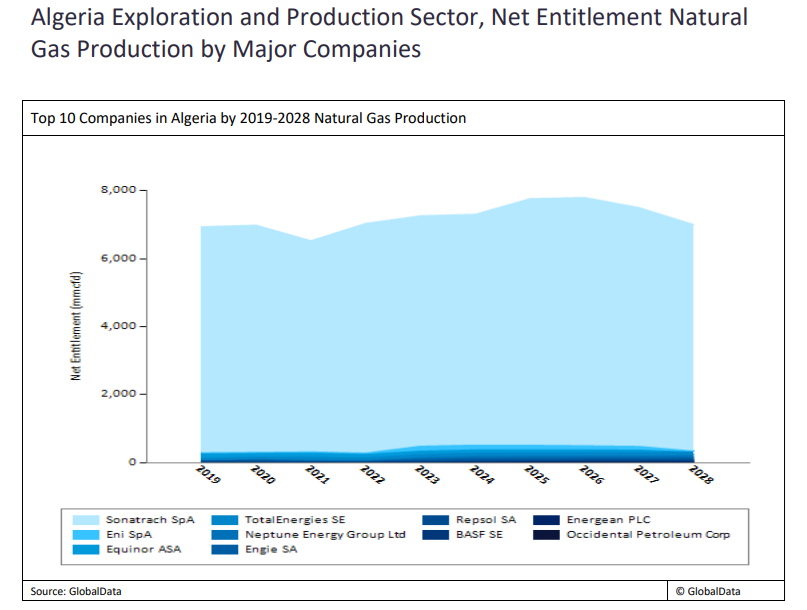

Sonatrach Petroleum Corporation is the leading exploration and production player in Algeria and is wholly owned by the Algerian government, controlling most hydrocarbons production in the country.

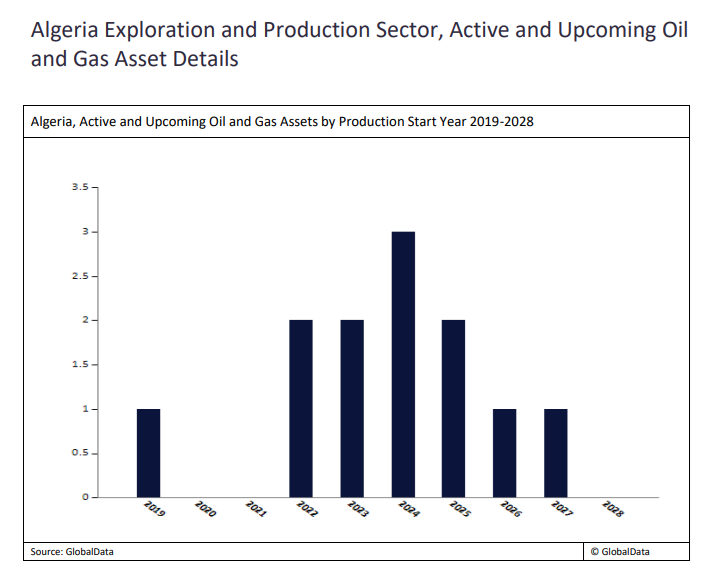

However, a new hydrocarbons law passed by the government in December 2019 was designed to attract additional foreign investments into exploration and production activities, and three deals have so far been signed with International Oil Companies (IOCs)

Algeria is accelerating exploration and production activities to reduce Europe’s dependence on Russian gas supplies, with Sonatrach completing a project to expand its Skikda port, which houses a 4 million mt/year LNG plant. This upgrade will boost the rotations of export LNG vessels and strengthen Sonatrach’s position in global markets. In January 2023, Eni and Sonatrach signed an agreement to increase energy exports from Algeria to Italy and potentially from Algeria to Europe. Algeria has recently overtaken Russia as Italy’s top gas supplier.

Algeria’s position as the largest producer of natural gas in Africa and its significant reserves highlight its importance in the global energy market. The country has experienced steady growth in natural gas production in recent years, driven by increasing domestic consumption and investments in export infrastructure. With its vast reserves and strategic location, Algeria is well-positioned to continue playing a key role in the natural gas industry.

Sonatrach partners with Huawei

Sonatrach manages a massive network of pipelines in Algeria, spanning 14,000 km. However, traditional manual inspection and continuous monitoring methods are both costly and inefficient, making it almost impossible to get real-time pipeline running status.

Now, a partnership with Huawei, unveiled at this year’s Mobile World Congress (MWC) in Barcelona, is providing a new smart solution for oil and gas pipeline inspection in Algeria.

The mission of the Sonatrach Joint Innovation Center is to collaborate with international partners in order to bring cutting-edge technology to the market for intelligent transformation, for example, saving on operations and maintenance (O&M) costs, finding fibre cuts fast, and proactively notifying users of any pipeline damage.

Pipelines are critical for the safe transportation of oil and gas. If a pipeline is damaged the network may break down, endangering national security. While drones can inspect some external areas of pipeline, underground pipes are obscured, and drones have a short range. Even using drones, manual inspection is time-consuming and costly.

Huawei’s solution: distributed fibre optic sensing technology

Huawei has developed an innovative pipeline sensing solution using distributed fibre optic sensing technology, which makes use of scattering or reflections, turning optical fibres into sensors. Using distributed fibre optic sensing to provide real-time, automated pipeline monitoring, improves efficiency and security over traditional manual inspection techniques. The system has an ultra-long-distance sensing of 100km.

“This solution is based on Huawei’s pipeline fibre warning solution and Life Network Service Management Process,” says Sana Lallali, manager of Sonatrach Joint Innovation Center. “When external construction occurs around the [buried] pipeline, the optical fibre deployed along the pipeline collects vibrations and transmits this information to the optical sensor device that is deployed in station, thereby locating the precise position.”

The new solution relies on Huawei’s OptiXsense EF3000, which continuously analyses vibrations detected by fibre optic cables alongside pipelines. Its AI-powered all-optical sensing technology helps the oil and gas industry build an industrial-grade optical fibre sensing network that is precise, easy-to-use, and stable. The system provides automatic and intelligent protection for pipelines, ensuring security of pipelines and efficient production.

The OptiXsense EF3000 can distinguish between a variety of events, including fibre cuts, manual excavation, and mechanical digging. The system can pinpoint errors to within ten metres and has ultra-high-precision identification of 97% event identification accuracy.

For instance, when mechanical construction is conducted around a buried pipeline, the fibre optic sensing system detects vibration information, analyses, and identifies the vibration information within one minute, and reports alarms and information to the management platform. Using this information, the monitoring personnel can dispatch an inspector to the construction site to stop the illegal construction and record the site information in the system.

And because the system features 24/7 real-time monitoring, it can also be utilised for predictive maintenance. Matamela Aubrey Mashau, CTO of Huawei South Africa Region, explains that this predictive maintenance is key to keeping the pipelines running smoothly, without incident.

“The fundamental technology within the solution is machine learning and AI,” Mashau says. “We have a dashboard that will be live in the command centre, allowing technicians to monitor it and perform maintenance around it. The solution gives you a lot of notifications as to where the problem is and how to remedy it. The good news is that it even provides proposed methods on how to do so.”

On partnering with Huawei, Sana Lallali says that digital transformation is critical to making the industry not only more efficient, but also safer. Lallali adds:

“We are satisfied with the joint innovation achievements we have done with Huawei, and hope that future cooperation with Huawei will promote the intelligent transformation of the industry.”

For more information on how innovative digital infrastructure enables intelligent transformation across industries, click here.