A plant must periodically undergo full or partial shutdown and start-up during its life duration. These shutdowns accommodate inspection, maintenance and revamp operations, as well as dismantling. During these operations it is very important to track and foresee the impact of system and sub-system on one another: it ensures worker safety and minimum downtime.

Systems Engineering solution are part of Dassault Systemes (3DS) comprehensive Plant Life Cycle Management solutions. They help engineers to formalize, share and manage a unified, cross-discipline systems development process is an RFLP (Requirement, Functional, Logical and Physical) infrastructure is at the heart of the solution. It enables technical requirements to be captured. It provides a complete traceability across the system definition: as well functional, logical, physical, as simulation aspects. All development efforts are centralized on a unified plant or asset definition enabled by Systems Engineering solution. So collaboration and innovation is fostered by bringing together on a common platform various disciplines, from mechanical, electrical cad, hydraulic, piping, to air-conditioning.

End-to-end process optimization, cross-discipline system modeling, simulation and analysis, which include dysfunctional analysis, are some of the many advantages delivered. This is a holistic approach to systems engineering that integrates all engineering disciplines. It helps to increase the physical asset quality and productivity. As a consequence it optimizes for cost and safety.

Attributes / key data:

- Management of requirement

- System modeling, simulation & optimization

- Dysfunctional and reliability analysis and simulation

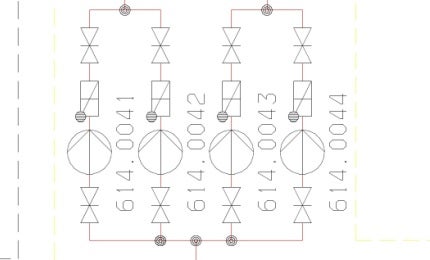

- Functional analysis and logical design

- Physical system architecture definition