Co.L.Mar’s patent-pending Acoustic Leak Monitor (ALM) leverages the company’s cutting-edge Acoustic Leak Detector® (ALD) technology to identify fluid leaks within marine structures in precise and reliable manner.

Co.L.Mar’s patent-pending Acoustic Leak Monitor (ALM) leverages the company’s cutting-edge Acoustic Leak Detector® (ALD) technology to identify fluid leaks within marine structures in precise and reliable manner.

The system has been designed to promptly detect gas and oil leaks arising in the area surrounding the installation point.

ALM is composed by a Subsea Unit (SSU) and a Top Side Unit (TPU) connected by a RS485 / Ethernet link.

Principle of operations

The SSU includes an omnidirectional hydrophone for the detection of the acoustic waves generated by sudden expansion of a fluid escaping from a leak on a pressurised installation.

The acquired acoustic signal is processed using proprietary algorithms by the DSP and FPGA based SSU electronics, so that just a limited amount of data has to be transmitted to the TPU.

The TPU software completes the detection process resulting in the generation of two parameters: the Signal Level, proportional to the energy content of the acquired signal, and the V Level, a proprietary parameter calculated with the statistical and spectral analysis of the data and very sensitive to a leak type signal.

The detection process is semi-automatic: the supervision of an operator is required to validate the alarm generated by the system.

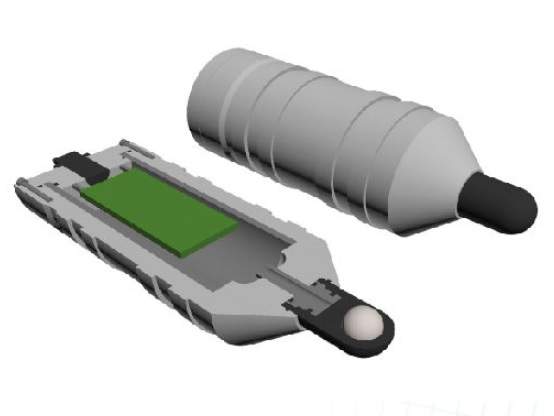

Subsea unit

The SSU is an intelligent unit to be installed by divers or ROV in the location to be monitored and connected via RS485 or Ethernet link to the TSU.

The electrical lead can be terminated with ROV / underwater electrical connectors.

The system has been tested simulating long term permanence at high depth with no maintenance required.

- The body of the unit has no metal parts exposed to the sea water in order to avoid corrosion issues.

- Max operating depth: 2,500m

- In-air weight: 5.5kg

- Power: 11VDC-35VDC

- Power consumption: <900mA at 12VDC

- Link: RS485 or Ethernet

- Dimensions: 110mm x 350mm

Topside unit

The TPU is composed of an industrial processing unit (based on NI Compact RIO hardware) for the generation of alarms and real-time processing and a custom heavy-duty industrial PC with touchpanel (or an existing Windows-based PC running proprietary Co.L.Mar. software) for system maintenance and alarm events inspection.

The two devices are connected to each other via Ethernet and can support one or more SSU.

The main functions of the system are to receive pre-processed data from the SSU, complete the detection process and set visual and acoustic alarms when needed.

The user interface of the inspection software is intuitive and allows an operator to validate the alarms.

The alarm validation is supported by the ‘virtual audio’ function; a synthetic audio representation of the ultrasonic signal acquired by the SSU reconstructed from its frequency components.

The other functions of the TPU are to monitor the SSU status and set up its monitoring parameters.

Communications and power supply

The data link and power supply can be provided by a dedicate cable connecting directly the SSU to the surface.

Alternatively, ALM can be interfaced with an existing subsea control module in with ISO 3628-6 standards.