Lesjöfors is a full-range international supplier of standard and customised springs, wire and pressings (flat strip components). The company dates back to 1675 and is today one of Europe’s leading springs manufacturers. Production is located at 14 different sites worldwide, with a total production area of more than 75,000m².

Lesjöfors supports customers in the oil and gas, aerospace and defence, hydraulics, telecommunications, domestic appliances, electrical switch gear, lighting and controls, nuclear, scientific medical and pharmaceutical industries.

Lesjöfors is a pioneer in spring production and has achieved and maintained the highest levels of technical expertise and innovative solutions. The company has a worldwide reputation for producing high-quality products, designed, developed and manufactured to exceed customer expectations.

Lesjöfors has more than 40 technicians who every day serve our customers with high-quality technical solutions for springs and pressings. Through our internal network of skilled employees, we ensure availability of the best possible expertise in each important customer project.

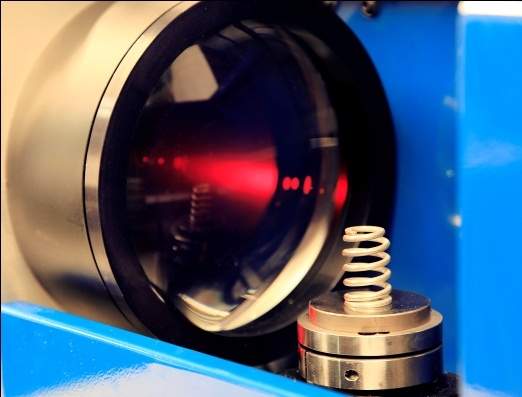

High-performance springs for extreme environments

High-performance springs are a necessity in many areas and can be the key to innovative solutions. To manage work in extreme environments with high temperatures and aggressive corrosion risk, so-called super alloys are used.

High-performance springs that can operate under extreme conditions are needed in several applications such as oil and gas extraction, thermal processing, marine, aerospace, power generation and petrochemical processing.

The exclusive materials used in these springs have a chemical composition which provides a combination of high strength, ductility and good mechanical properties, even when working at high temperatures and in highly corrosive environments.

Disc springs, compression springs, torsion springs, tension springs and leaf springs

Lesjöfors has a wealth of experience, technical calculation skills and excellent production capacity, serving a range of major and diverse industries where super alloys springs are needed.

Examples of product areas are disc springs, compression springs, torsion springs, tension springs and leaf springs. They are often nickel or cobalt alloys. For selection of the best material, knowledge and experience of these materials is crucial.

Lesjöfors is able to advise on suitable material options based on the application and environment, design the spring and produce to order.

Wire, strip and sheet super alloys

Lesjöfors keeps a wide range of stock of the super alloys in wire, strip and sheet form, suitable for most types of springs, allowing us to offer short delivery times.

The following alloys are kept in stock:

- Inconel X-750

- Inconel 718

- Nimonic 90

- Titanium

- Hastelloy C-276

- MP 35N

- AISI 316

- Alloy 3J21 (Elgiloy)

The last mentioned is the new super alloy 3J21, known under other names such as Elgiloy and Phynox. It is a cobalt-chromium-nickel alloy which gives it a combination of high strength, ductility and good mechanical properties, and it is age hardenable. Alloy 3J21 also has excellent fatigue life, corrosion resistance in numerous environments and is non-magnetic.

Heavy-duty hot coiled compression springs

Lesjöfors is one of few spring manufacturers of hot coiled springs in Europe. These massive and strong compression springs are made in materials with dimensions ranging from 5kg to 350kg with a rod up to 65mm. Maximum lengths of the steel wire / bars is 14m.

The hot coiled springs from Lesjöfors are made in Åminnefors, Finland, and have wide usage in heavy industries, with applications in, for example, powerful safety actuators in subsea oil wells and equipment.

Development partner

The performance of your spring or strip component is crucial for the function of an application. To determine the product’s performance, Lesjöfors makes calculations and simulations that later are verified through measuring and testing.

We have the capacity to calculate, measure and test all types of springs, from very small and thin strip components to several hundred kilo heavy coil springs.

Lesjöfors’ spring experts can give you advice and recommendations for the best possible performance of your spring. At what temperature will your spring operate? Even a small divergence from room temperature can affect the performance of the material. Is there a risk of corrosion? The most common spring problem is corrosion. Different environments require different materials and/or surface treatments.

Spring technological customer support

Lesjöfors’ network of spring experts include areas such as material, surface treatment, dimensioning, prototyping, manufacturing, testing and quality assurance. We cooperate with world-leading spring material suppliers and have access to material data for the best spring materials. We use the most up-to-date methods to support you during the design of your specific spring.

Our spring engineers work in close cooperation with our customers.