BVM Corporation manufactures handling tools for onshore and offshore drilling.

Handling tools can be used in a variety of ways for suspending, moving and rotating pipe in and around the well centre and on the drill floor, all of which play a critical role in modern drill pipe operations.

We aim to offer high-quality tools at competitive prices and the flexibility of a smaller company, so we can make specialised sizes and configurations to meet our customers’ needs.

Oil field drilling handling tools

Our portfolio includes drill pipe and tubing elevators, elevators / spiders, rotary slips, manual single-joint elevators, casing slips, manual side-door elevators, weldless links and more. Our products are built to optimise your drill pipe capabilities.

Elevators / spiders are available from us with capacities ranging from 200t to 750t and a range of 2 3/8 to 24 ½ and in the following types:

- Side Door: 90 Deg

- Center Latch: 18 type

- Single Joint

- Center Latch: TA / RA type

- Sucker Rod

- Slip Type

We offer C, B, DB, MS, LF, AAX, H and SDD manual tongs; T, C and MP safety clamps; rotary, casing, UC – 3, conductor pipe and drill collars manual slips and standard, big eye and electro weld elevator links.

Our Kelly spinners and tubing spiders are available in both pneumatic and manual types. We also offer pick up and lay down machines, as well as hydraulic power units which operate on diesel using Deutz 4-5-6 cylinder engines and are available with or without turbo.

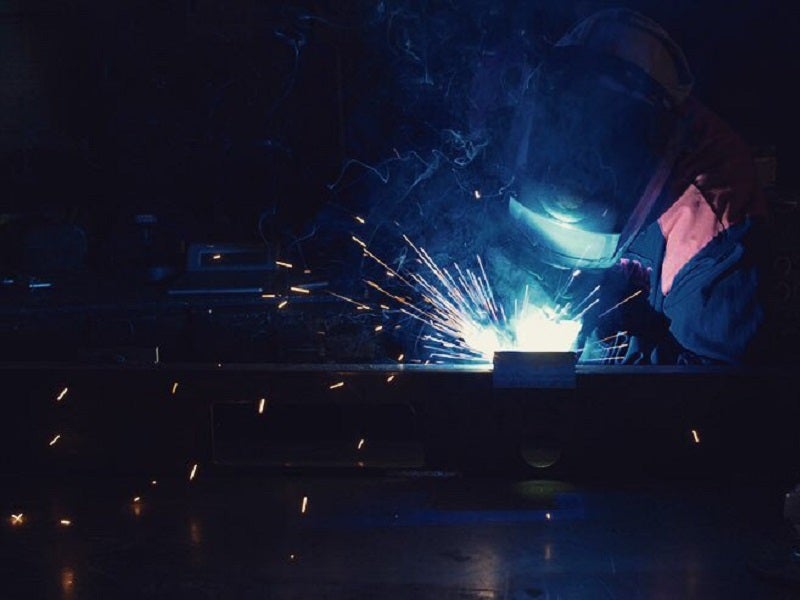

Load testing, repair and recertification services

BVM offers technical and maintenance support and is qualified to perform load testing, repair and recertification on its tools.

Our manufacturing plant-based repair and recertification facility can give you access to our supply of new parts, skilled and certified welders and load test technicians as well as our non-destructive (NDE) and quality control specialists. We use the same NDE testing, load testing and certified welding procedures as we do for our new and existing tools. With a sandblasting and factory paint booth, we will repaint a facility after testing.

Quality assurance in the offshore industry

BVM’s certifications include API 7K-0500, API 8C-0307 and ORI ISO 9001-2015.

These certifications demonstrate that we have the discipline to identify, understand and fully implement our customers’ requirements and expectations. They help us to minimise production waste and costs while providing the high-quality goods and services that our customers expect.

By providing this visible commitment to our customers, we aim to give you confidence in our company and our products.

About BVM Corporation

BVM has been in the business of manufacturing oil field tools for more than 30 years. It was founded in 1987 by Norbert `Bert’ Vogler. It maintains its operations under the direction of Bert and his son Andre.

In recent years, we have been concentrating on expanding our line to include tools that can handle the larger sizes and heavier loads required for the deeper drilling and multiple strings originating from a single drill site. We continue to offer the smaller and lighter tools needed for onshore drilling and reworking of wells.

Our products are all manufactured in our factory in Denver, Colorado, US, and available globally. We are currently in the process of adding new machinery and space to our factory to ensure increased production capacities.