SPINNER is one of the world’s leading manufacturers of high-performance rotary joints.

Fibre-optic rotary joints in particular require exacting optical and mechanical manufacture. And SPINNER ideally meets these requirements. We provide all of the mechanical and optical parts in top quality from a single source. In addition, SPINNER is able to offer combinations of fibre-optic and RF rotary joints.

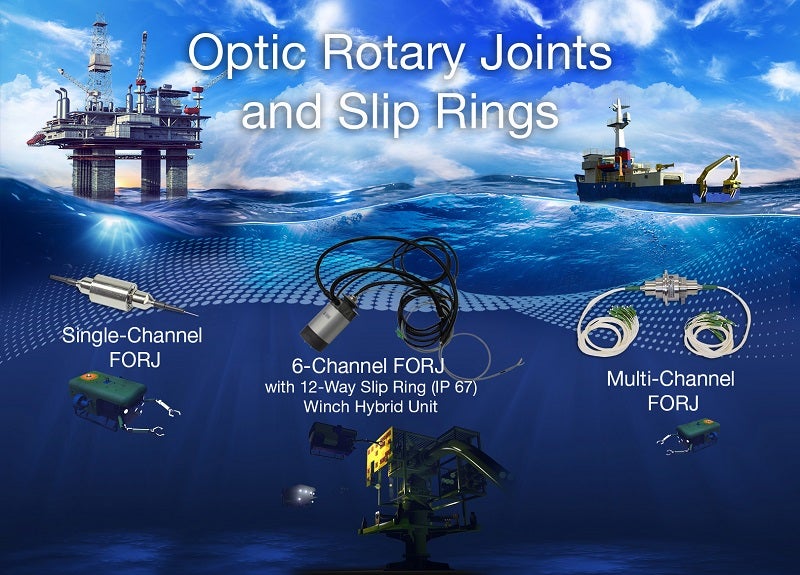

SPINNER supplies innovative customer-specific solutions for offshore applications, focusing on:

- Remotely operated vehicles (ROVs)

- Winches (surface and subsea)

- Camera systems (surface and subsea)

- Drilling systems

In everything from design to implementation, SPINNER supports customers worldwide with fibre-optic rotary joints and multiplexers, electrical slip rings, rotary joints for media, and hybrid joints for offshore and demanding undersea applications.

Fibre-optic rotary joints

fibre-optic rotary joints (FORJS) are used, for example, for transmitting communication or sensor data through winches. They need to be especially robust for these applications. SPINNER supplies products with 1, 2, 3-4, 3-8, 7-21, and 21-54 channels and all fibre types (single-mode, multi-mode, and thick-core fibres). All of them exhibit minimal return (reflectance) losses and are built and tested to ensure compliance with shock and vibration requirements.

So that the benefits of FORJs can be fully utilized, SPINNER also offers multiplexers that are able to convert RS-422, HD-SDI 1.5 Gbit, HD-SDI 3.0 Gbit, video, ethernet, GigE and other data prototcols. They are engineered to ensure reliable transmission in demanding undersea applications while minimizing the amount of required space.

SPINNER also provides hybrid joints in which high-current slip rings are combined with FORJs. These systems are mainly used above the water, but with pressure compensation are also suited for underwater applications.

A slip ring is an electromechanical device that enables transmission of energy and electrical signals between a stationary structure and a rotating one. It can completely rotate around its axis multiple times (n x 360°) or else only turn through a smaller angle, for example 60°. In offshore applications, rotary joints of this kind are also referred to as swivels. They can swivel or continuously rotate while simultaneously transmitting electric current or data.

For high-speed data transmission or data transmission in EMI/EMC-sensitive environments, SPINNER carries a number of dedicated FORJs:

Single-channel rotary joints

The SPINNER FORJ 1.17 rotary joint is designed for the most adverse of environments, and to endure strong vibrations, jolts and shocks. It is also resistant to humidity and seawater.

This IP68-rated design meets the requirements of the offshore and underwater vehicle industries.

The company also provides a specialised version of this single-channel rotary joint with pressure compensation for deep sea applications for depths of up to 4,500m.

Multi-channel rotary joints for adverse environments

The SPINNER FORJ x.40 rotary joint provides market-leading compactness with multichannel solutions with up to six channels.

Featuring a 39.5mm-diameter outer housing, the multichannel joint is available in single-mode, multi-mode, and mixed-mode fibre configurations.

For applications in challenging environments, SPINNER FORJ x.60 withstands high levels of vibrations, jolts, and shocks, and is highly resistant to humidity and seawater.

Its design responds to the needs of military and offshore applications, and is IP65-rated.

The SPINNER FORJ x.60 joint supports up to 20 channels in mixed fibre mode assemblies, and up to 52 channels in either single-mode and multi-mode fibre formations.