Mechanica is a Norwegian multi-disciplined company with in-house capacity within engineering, CNC machining and hydraulic assembly.

We mainly focus on the design and fabrication of remotely operated subsea tools, such as cleaning tools, seal handling / replacement tools, refurbishment tools, jacking tools as well as machining, drilling and cutting tools.

We are also a manufacturer of specially designed subsea accessories such as lifting anchors, hot stabs and receptacles, worm gears and winches.

Deepwater ROV tooling

Mechanica is a recognised supplier of deepwater ROV tooling solutions, specialising in hub cleaning, and the refurbishment and replacement of hub seals. Through our products, we provide advanced, robust and dependable technology.

In order to reduce lead times when it comes to the engineering and fabrication of purpose-made tools, we have developed a number of standardised products and accessories.

Hot stabs and receptacles

Mechanica has developed a complete range of hot stabs and receptacles in accordance with the ISO 13628-8A (API 17H) and API 17D standard. Bore and check valves are designed for high flow capacity and minimum pressure drop.

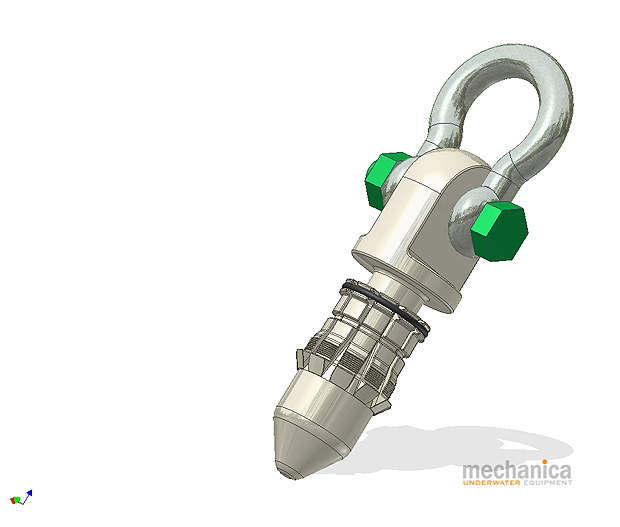

Subsea lifting anchors for ROV installation (patented)

Subsea lifting anchors for ROV installation are designed to save ROV operation time. These can be delivered in several sizes with a capacity of 10Te, 13Te, 5Te and 30Te and with angle deviation up to 90° from the direction of the drilled hole.

Standard ROV handles

We offer field-proven flexible joints for standard handles in AISI 316 and NBR. Available in two different sizes, standard ROV handles are manufactured in Super Duplex. Both fishtail and D-handle are available from stock.

Subsea worm gear

Subsea worm gear is available for use in ROV tooling applications where you need a compact, oil-filled and compensated transmission unit. These are available in three main sizes with numerous alternative ratios, output torque from 100Nm to 1,500Nm.

50kN subsea winch

Mechanica offers a compact 50kN subsea winch with focus on the optimisation of the weight / performance ratio to carry out demanding subsea tasks. The winch has a small number of components, is oil filled and a compensated transmission unit. Outfitted with composite rope, this is a reliable and attractive product in the market.

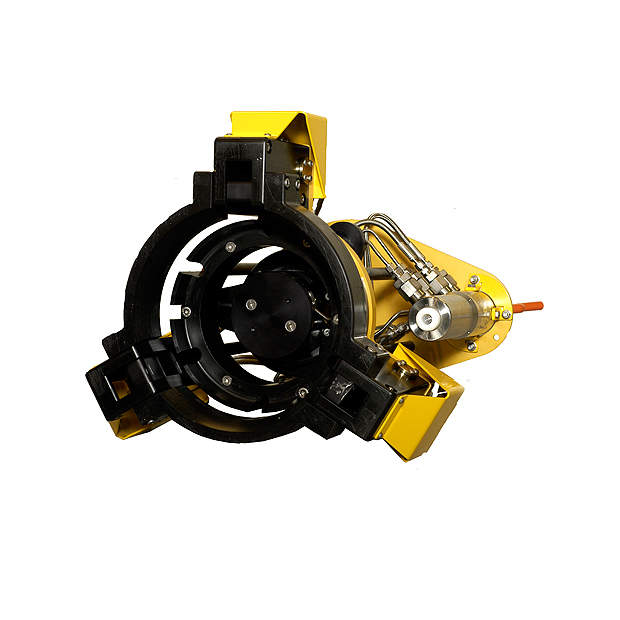

Core drill tool for subsea structures

The core drill tool (CDT) ø100 is designed to drill ø100 holes in subsea structures by operation from ROV. It has robust hydraulic transmission and is easy to install. The tool is fastened to the base by four-piece magnets, or alternatively with suction pads or clamping.

ROV-operated hot tapping tool

In order to perform hot tapping for small bore pipes such as hydraulic lines, Mechanica has developed an efficient, ROV-operated hot tapping tool. For operations including the blanking of pipes, the hot tapping tool is designed to be operated in combination with the Mechanica pipe squeeze tool.

Cleaning and seal replacement tools

Mechanica has delivered a variety of cleaning and seal replacement tools for a number of different hub configurations. Our tools are field proven and state-of-the-art solutions to obtaining efficient and reliable operations.

HUB refurbishment tools

For the repair of more severe damages, we have supplied HUB refurbishment tools for both monobore and multibore hub configurations for several projects. Refurbishment may also involve lead print of damages on hubs and seals, honing, wet-rub and polish.

Purpose-designed ROV tooling for offshore projects

On several occasions, Mechanica has been involved in major projects from the moment a severe problem has occurred until operation has been completed. The following examples describe just two of them, both successfully executed in close co-operation with our customers and involved partners.

Machining tool for removal of stuck wellhead seat protector

The removal of a deformed and stuck seat protector was successfully performed by application of a purpose-designed seat protector machining tool for internal machining of seat protector wall, equipped with both axial and radial feeding.

The operation was successfully completed and the seat protector was removed within the scheduled time table and without any damages to the wellhead.

This is probably the first time a ROV-operated tool package for removal of a stuck wellhead seat protector has been designed and applied. The cost saving compared to solutions depending on support from a rig is substantial. The application of these principles could be relevant for other tools / items stuck in a wellhead or even for cleaning of a wellhead seat.

Tool package for the repair of leakage on the Byggve Well

A leakage between the Annulus Wing Block and the Annulus Vent Valve, located outside the existing barriers on the horizontal production tree, was found on the Byggve Well 25/5 (Total E&P Norge AS).

Mechanica was awarded the contracts for the design and manufacture of tools necessary to access and blind the hole. The tool package consisted of, amongst others, a core drilling machine for obtaining access, tools for squeezing, cutting and blinding of hydraulic piping, a quad wrench tool and a gripper tool to release and remove the bolts and flange, a number of pick up tools, wrench tools and lifting devices to remove the valve, several refurbishment tools and plug installation tools to blind the hole, verify access and install a permanent plug in the annulus block, and finally lifting devices for the reinstallation of the roof on the Christmas tree.