As one of the world’s leading specialty metals companies, Allegheny Technologies Incorporated (ATI) offers the broadest array of next-generation materials and innovative, problem-solving technologies that can be applied to the most challenging production environments – from downhole and offshore applications to unconventional oil sands development.

Today, the quest for oil and natural gas demands cutting-edge technologies and advanced materials designed to withstand ever more sophisticated applications in increasingly daunting conditions. ATI Oil & Gas’ equipment is designed to deliver in these environments.

High-performance, cost-effective specialty metals for the offshore industry

ATI Oil & Gas represents the combined capabilities of ATI’s business units serving the oil and gas market, including ATI Allegheny Ludlum, ATI Allvac, ATI Wah Chang and ATI Engineered Products.

Collectively, ATI Oil & Gas delivers the widest range of high-performance, cost-effective specialty metals and products in the industry.

Specialty stainless steels, titanium and stainless alloys, and nickel-based alloys for offshore applications

Products for offshore topside applications include:

- Specialty stainless steels for firewalls / blastwalls, instrumentation tubing, piping and racks, and other structural applications

- Titanium and stainless alloys for heat exchangers, water separation, desalination and fire suppression systems, including piping and tubing, and pump and valve castings

- Nickel-based alloys and specialty steels for tanks and vessels

Specialty metals and alloys for subsea and downhole applications

Products for subsea applications include:

- Specialty and stainless steels for umbilicals, flexible and rigid flowlines and risers, flying leads and jumpers

- Nickel-based alloys for clad piping and buoyancy module straps

- Titanium and nickel-based alloys for subsea valves, valve internals and tubing hangers

Products for downhole applications include:

- Nickel-based alloys for well heads, submersible pump shafts, injection tubing, mud motors and other completion tools

- Specialty stainless steels for non-magnetic drill collars and duplex capillary tubing

- Titanium alloys for wireline components and housings

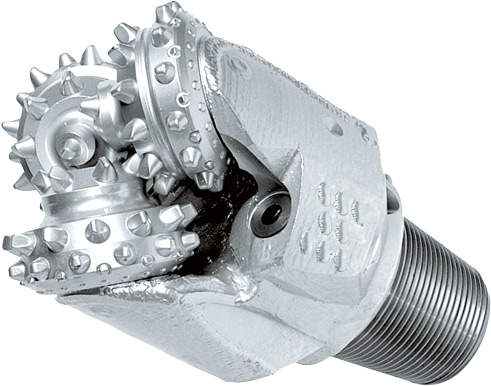

- Tungsten carbide drill bit bodies and compacts for rotary cone bits

Threading, turning and drilling tools for forming and shaping drilling string components

ATI’s high-performance products are engineered in many fabricated forms, including slab, plate, sheet, strip, foil, ingot, billet, bar, rod, tube, wire, extrusions, forgings, castings, custom shapes and semi-finished and finished parts.

ATI Oil & Gas also provides premium cutting tool technology, such as threading, turning and drilling tools for the forming and shaping of components within the drilling string.

Metallurgical expertise and breakthroughs in proprietary alloys and processes

ATI’s metallurgical expertise sets us apart, as we continue to produce breakthroughs in proprietary alloys and processes. Our products are engineered for maximum strength, corrosion resistance, longevity and performance, making them ideal for the most challenging oil and gas applications.

Our oil and gas products are designed and manufactured to meet precise performance specifications and the stringent certification standards of:

- NORSOK

- Achilles JQS (should this be added)

- National Association of Corrosion Engineers (NACE)

- American Petroleum Institute (API)

- American Society of Mechanical Engineers (ASME)

- American Standards for Testing Materials (ASTM)

With the industry’s most complete range of specialty metals solutions, our technical and metallurgical depth and our unsurpassed manufacturing capabilities and secure supply chain, ATI Oil & Gas is uniquely positioned to deliver materials and products that meet our customers’ most challenging needs – improving production, exploration and development now and in the future.