AMETEK Specialty Metal Products is a specialist manufacturer of high-performance metal tube, strip and powder products for hostile and corrosive oil and gas applications.

Our high-quality metal products deliver outstanding wear, pressure and corrosion resistance for extended product life, reduced downtime and maintenance costs in extreme environments.

Products include:

- High-Pressure Stainless Steel, Super Duplex and Nickel Alloy Tubes

- High Lubricity and Hardness Engineered Shaped Components

- Hardenable and Conductive Metal Strip

- Hardfacing Powder Coatings

- Corrosion Resistant Clad Plate

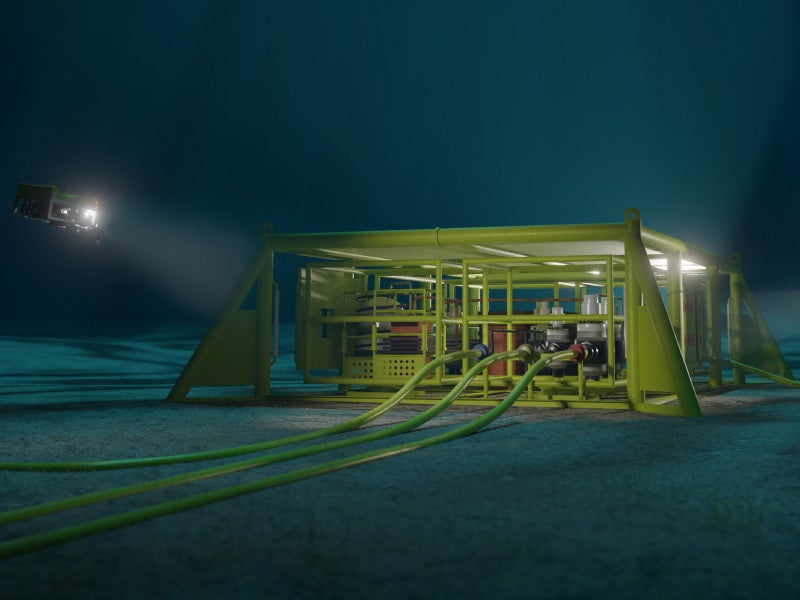

High-pressure, precision tubes

High quality, NORSOK-approved metal tubes custom-engineered to perform without failure for high corrosion and pressure resistance up to 60,000psi.

Alloys

Seamless and welded stainless steel, super duplex, titanium and nickel alloys.

Sizes

Outside diameters from 0.3mm (0.01in) to 45mm (1.77in). Specialist items up to 63.5mm (2.5in) on request.

Applications

- Downhole hydraulic control lines

- High pressure control & instrumentation

- Downhole data logging/smart wells

- Downhole MWD/LWD pressure housing

- Topside and onshore instrumentation

- Subsea Xmas trees and manifolds

- Flowmeters

Super Duplex tubes

Our NORSOK-approved Super Duplex alloy 2507 tubes (UNS 32750) are custom-engineered for the most aggressive oil and gas and chemical process applications.

Sizes

Our tubing sizes typical for Super Duplex range from 3.18 mm (0.125in) to 31.75mm (1.25in) outer diameter OD in seamless form.

Advantages

- NORSOK-approval

- Made to order in specialist non-standard sizes

- Superior strength and corrosion resistance

- Significantly extended product life

- Short lead times and small batch sizes

Greater corrosion resistance than standard duplex grades

Super Duplex stainless like S32750, is a mixed microstructure of austenite and ferrite (50/50) which has improved strength over ferritic and austenitic steel grades. The main difference is that Super Duplex has a higher molybdenum and chromium content which gives the material greater corrosion resistance than standard duplex grades.

Applications

- Offshore platforms

- Fire-fighting systems

- Injection & ballast water systems

- Heat exchangers

Hardfacing powder coatings

Our surface coating powders are manufactured to have precise thermal spraying characteristics to enhance the performance of a workpiece.

Advantages include improved hardness and machinability, corrosion resistance, wear and heat resistance to extend the life and offer total component cost savings.

Alloys

- Nickel base Alloys, both simple and Inconel® types

- Nickel-Chrome-Boron Systems – AMS 4775, 4776, 4777, 4778, 4779

- Nickel-Chrome Molybdenum systems such as Hastelloys®

- Tool Steels up to 70+ HRC

- Copper-Nickel and Nickel-Copper Monels®

- Cobalt Alloys such as Stellites and Tribaloys®

- Aluminides (both Ni-Al and Fe-Al)

- Stainless Steels

- Aluminum Bronzes

Applications

- Hardfacing: thermal spray, spray and fuse applications for highly abrasive and corrosive environments. Oil field equipment includes drill rods, shafts, tubes, couplings, cutter bars, augers, cylinders

- Precision chemical filtration in extremely corrosive environments

- Powder metallurgy, corrosion protection, and geometric re-tolerancing

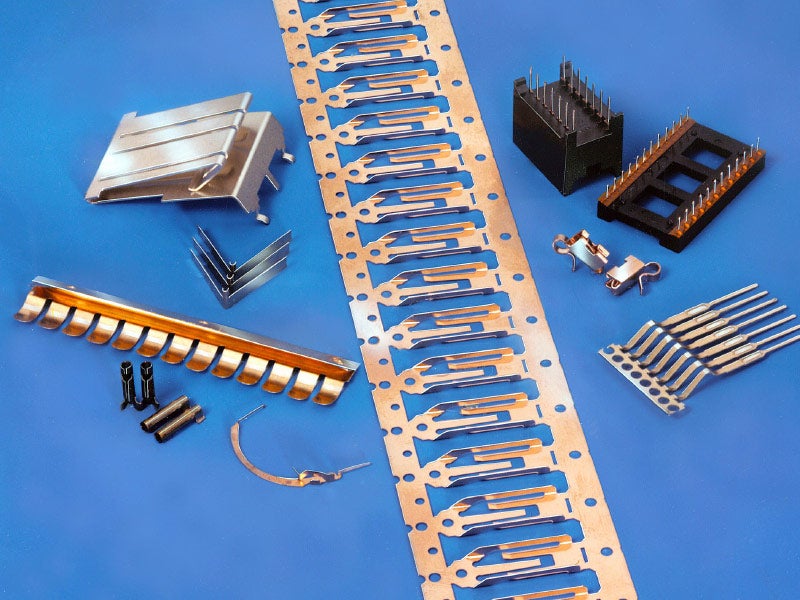

Hardenable and conductive metal strip

Our high-performance metal strip products are manufactured via wrought powder metallurgy.

Our materials can be roll-tempered to desired mechanical properties. Our Spinodal products (C72900 and C72650) can be further hardened for spring properties in electronic connectors. Our Nickel products are available with the highest conductivity of commercially available Nickel products.

Alloys

We offer two Spinodal alloy grades AM388™ (UNS C72650) and Pfinodal® (UNS C72900). These alloys are produced through wrought powder metallurgy as copper-based products with nickel and tin additions. Our pure nickel strip grades include nickel 200, 201 and 270.

Applications

- AM388™ (UNS C72650) strip for non-sparking tools

- AM388™ (UNS C72650) Pfinodal® (UNS C72900) strip for electronic connectors

- Pfinodal® copper alloy strip (UNS C72900) for parabolic cone-shaped charges used in well perforation

- Nickel 201/270 strip for rechargeable battery components

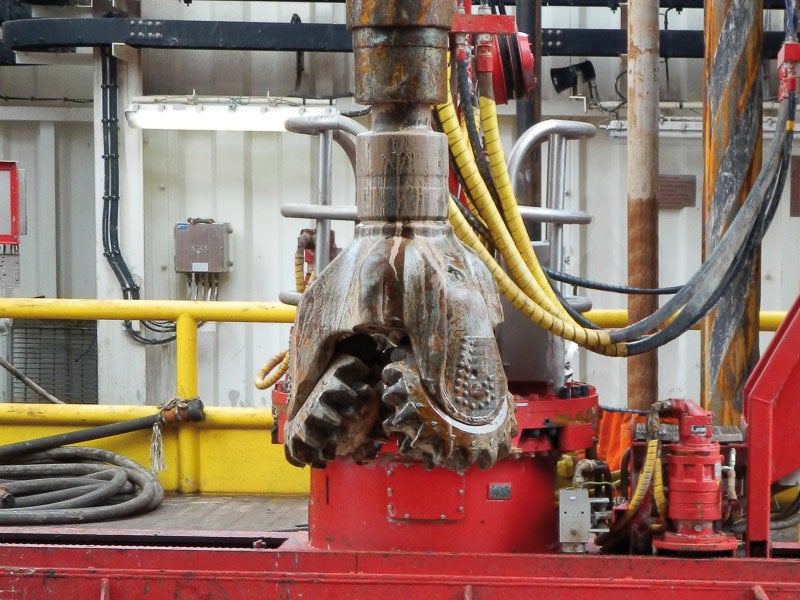

Engineered shaped components

We manufacture high strength Pfinodal® (UNS C72900) bearing materials used to extend drill bit life in demanding drill bit bearing applications.

Our production processes and heat treatments combine to ensure the high hardness and non-magnetic properties required in a bearing material for bearing sleeves, bushings, washers and caps.

Alloys

Spinodal alloy grades: AM388™ (UNS C72650) and Pfinodal® (UNS C72900)

Applications

- Pfinodal® (UNS C72900) ESC for tri-cone drill bits

- Pfinodal® (UNS C72900) shaped charges for well perforation

Corrosion-resistant clad plate

Roll bonded clad material combining corrosion-resistant alloys designed to meet critical standards in pressure vessels. Our high-performance clad plate incorporates two or more metals for superior strength, pressure and corrosion resistance whilst reducing weight.

Sizes

Available in standard widths to 120in and length to 540in. Thickness ranging from 3/16in to 1in.

Alloys

304L, 316L, 410S, Ni 200, Monel ® 400, Inconel ® 625, Inconel ® 825, Hastelloy ® C276

Applications

Pressure vessels and autoclaves.

AMETEK Specialty Metal Products

AMETEK Specialty Metal Products (SMP) is a division of AMETEK, Inc. a leading global manufacturer of electronic instruments and electromechanical devices with annual sales of approximately $5 billion.

With 80 years of engineering expertise, the Specialty Metals division consists of five businesses and operating facilities in the United States and the United Kingdom and include AMETEK SMP Eighty Four, Superior Tube, Fine Tubes, Hamilton Precision Metals and AMETEK SMP Wallingford.

All are proven experts in the manufacture of advanced metallurgical products for mission-critical applications.