VWS Westgarth specialises in the turnkey design and build of water treatment plants for upstream oil and gas markets. We are the world leader in seawater sulphate removal packages (SRP), and also supply complete produced water treatment and wash water systems on a global basis.

A blue chip client base coupled with extensive experience of offshore engineering standards and requirements means that VWS Westgarth is very well placed to continue to develop and install market leading solutions. VWS Westgarth is a member of the VWS Oil & Gas group within Veolia Water Solutions & Technologies (VWS), the world’s largest water treatment company.

Water injection systems

Water injection is the action of injecting water into a reservoir to maintain pressure and encourage hydrocarbons to the producing well. In many situations, the most convenient fluid for injection is the produced water from the well. Injection is also a convenient method of produced water disposal. In an offshore environment, seawater is often the preferred source of injection water.

The quality of the water for injection, from whatever source, will be required to be of a standard that will not cause problems such as plugging and/or scaling of the injection equipment. This is an important issue, especially offshore, where drilling a new well is extremely expensive.

In addition, because a reservoir is effectively sterile, injecting water containing oxygen and bacteria can cause ‘souring’ of the reservoir. A ‘sour’ reservoir is one where there is the presence of hydrogen sulphide (H2S) in the hydrocarbons. Souring reduces the value of the produced hydrocarbons and requires expensive production equipment and materials to cope with the aggressive nature of the produced fluids. Typical contaminants that need to be removed from injection water are:

- Hydrocarbons

- Solids

- Scaling compounds such as sulphate

- Sulphate reducing bacteria

Sulphate removal systems

Sulphate removal systems work through the injection of water into the reservoir to enhance oil recovery (EOR) by maintaining the reservoir pressure and to sweep displaced oil towards the production wells. Sea water typically contains 2,650mg/l of sulphate ions. Formation water in the reservoir will contain barium from a norm of 200mg/l to a high of 2,500mg/l. This barium will react with the injected sea water sulphate ions causing barium sulphate scale.

The industry recognised solution is to remove sulphate from sea water before injection; this also helps prevent well souring by controlling sulphate reducing bacteria (SRB). The "Sulphate Removal Process" was developed and patented by Marathon Oil/Dow in the late 1980s, and the technology design granted to global sub-licensees.

Produced water treatment systems

Produced water is any water that is ‘produced’ to the surface from an oil or gas reservoir along with the oil and gas. The contaminants need to be removed to enable the produced water to be re-used or disposed of. There are a number of options available for the disposal or reuse of produced water, each of which will have different water treatment criteria associated with it:

- Surface disposal into the sea, watercourse or into evaporation ponds, subject to local environmental regulations

- Injection into a disposal well, either a watered out part of the reservoir or to a disposal formation

- Reinjection for pressure maintenance, replacing sea/aquifer/river water as the source of water injection

- Reuse for irrigation or as industrial process water

Water treatment system turnkey package

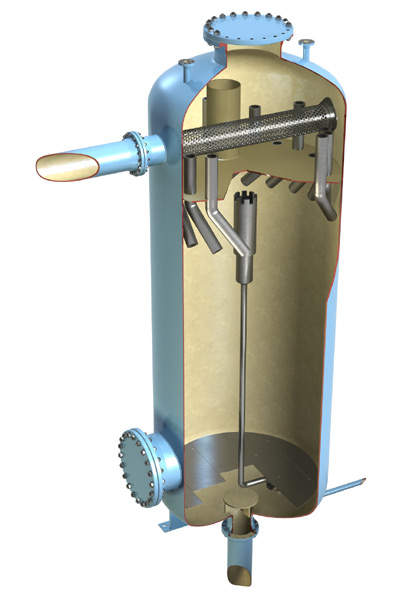

VWS Westgarth engineers, procures and project manages the complete produced water treatment system including:

- Oil/water plate separators

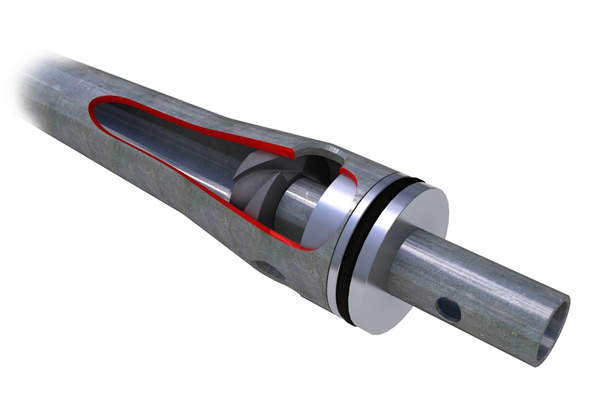

- STREAMLINER™ de-oiling hydrocyclones

- De-sanding hydrocyclones

- Degassing plant

- Cophase™ compact flotation units (CFU)

- Macro porous polymer extraction (MPPE)

- Dual-media filters

- Ultrafiltration with ceramic membranes

- Membrane sulphate removal

- System healthcare