Vee Bee Filtration, the world-leading designer, manufacturer and supplier of Strainers, Filters and Pressure Vessels has released a White Paper that details the use of simulation technology to optimise the design and performance of strainers engineered for LNG vessel transfer and liquefaction process plants.

The paper, entitled ‘Impact of simulation technology on design and engineering of optimized strainers’, looks in detail at the benefits of utilising simulation techniques during the design and engineering of pipeline strainers and the resultant prediction and pre-validation of the flow performance. Accuracy of performance prediction leads to greater reliability and protection of the LNG liquefaction and transfer systems during their expected operational life cycle.

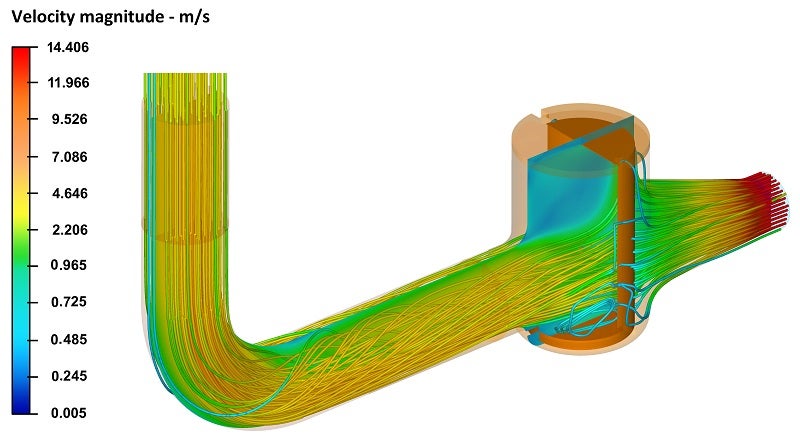

The White Paper objectively details how the simulation technologies employed by Vee Bee, focusing on Computational Fluid Dynamics (CFD) and Finite Element Analysis (FEA) modelling, provide an accurate insight into the real-life performance of the strainers. This allows client engineers to design systems to operate up to and within the safe operating limits of the strainer at the highest flow efficiencies.

“For critical strainer applications, we often recommend engineering contractors to employ an optimised solution, ensuring that the strainers are effective in their filtration duty whilst minimising their impact on the system flow efficiencies,” says Sales Director Guy Downie. “Engineering Contractors benefit from predictable performance from installation, shorter commissioning and start-up times and lower overall associated costs. Ultimately the site operator has the greatest benefit as these engineered strainers are able to perform to the highest standards with a minimum of maintenance for their operational life.

“We identified some time ago that by adopting a simulation driven engineering philosophy we could reach levels of efficiency in the design of our strainers that was far beyond anything the market had seen before,” Guy adds. “The application of this approach is well suited to LNG projects due to the criticality of output performance and the expensive assets the strainers are designed to protect.”

“The broader impact of poor strainer selection may include risk of damage to critical equipment, resulting in high potential replacement cost, commensurate downtime, exposure to litigation, damaged reputation and raised insurance premiums.”

“The comprehensive understanding Vee Bee has developed of strainer flow performance provides a pre-validated foresight of strainer performance at an accuracy level which has never been achievable before,” says Guy Downie.

“Due to the benefit this approach brings to our customers, we have taken the decision to share our approach more widely with the formal release of this White Paper, driving better understanding and raising the standard for the whole sector,” he concludes.