Liqui-Cel® membrane contactors use a microporous hollow fibre membrane to remove oxygen from the water stream. Gas flows on one side of the membrane, and liquid flows on the other side at a higher pressure relative to the gas stream. Because the membrane is hydrophobic it prevents intrusion of liquid into the pores and acts as an inert support that allows direct contact between a gas and a liquid phase without dispersion.

Applying a vacuum and/or an inert sweep gas to the gas phase lowers the partial pressure of the target gas. This creates the driving force for dissolved oxygen in the liquid to transfer through the hollow fibre membrane pores. The transferred oxygen is then carried away by the vacuum pump or sweep gas.

Liqui-Cel membrane contactors have been used for over 20 years in many industries, including microelectronics, power, food and beverage, ink jet inks, coatings, pharmaceutical, laboratories and many others. To date, over 2.7million gpm (613,000m³ per hour) of liquids have been processed.

Reliable deoxygenation in a compact system

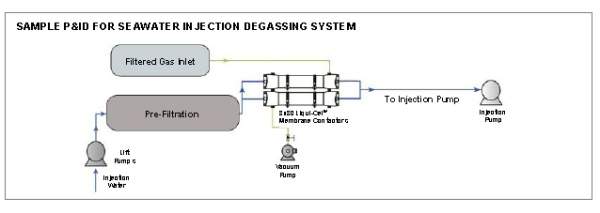

Liqui-Cel membrane contactors are reliable, compact devices used to control dissolved gases in liquid streams. On offshore platforms, 8in x 80in high pressure contactors deoxygenate seawater for water injection / water flooding down to 10ppb, using a footprint that can be nearly 40% less than a vacuum tower.

The weight reduction can be substantial. The reduced weight lowers the cost associated with a support structure that is needed for water-filled deaeration towers that have historically been used in deoxygenation.

8 x 80 membrane contactor system

A smaller footprint and reduced weight are not the only benefits of using Liqui-Cel membrane contactors. These devices maintain positive pressure after degassing which may reduce booster pump capacity requirements to lower CAPEX. Unlike bulky deaeration towers, membrane contactors are modular and can be easily expanded to meet water capacity requirements even after initial installation.

Additionally, chemicals used to deoxygenate the seawater may be reduced or even eliminated depending on operating conditions. The devices are ASME code-rated to 300psi to handle high inlet pressures. Similar in appearance to remotely operated vessels, maintenance and cartridge changes are familiar to platform operators.

Membrane contactors for degassing applications

In addition to water flooding applications, Liqui-Cel membrane contactors are used to remove dissolved oxygen and carbon dioxide in boiler feedwater and produced water for reinjection applications.

In boiler feedwater applications, Liqui-Cel contactors are installed to help reduce corrosion and pitting within the boiler and piping to protect capital investment. Degassing boiler feedwater is a common application in many industries, such as power generation. Several oil derricks are also using membrane contactor for this application.