Hamworthy Water Systems has a track record of delivering reliable and tailored wastewater treatment systems to the offshore market. We aim to support our customers in meeting new industry and environmental legislation, developing technologies to gain efficiencies in the oil and gas markets. Our market-led wastewater treatment innovations ensure that we can supply easy-to-install, trouble-free systems with enhanced safety for some of the harshest environments on the planet.

Wastewater treatment for offshore

Hamworthy’s Super Trident sewage treatment plants have been installed on FPSOs, seismic vessels, drillships, semi-submersible rigs / jack-up rigs, production test ships, FSOs, LNG and LPG FPSOs, shuttle tankers and intervention vessels. Since 1963, over 10,000 Super Trident sewage treatment plants have been installed around the world, providing extensive operational and performance benefits.

Due to the extended aeration process utilised, Super Trident sewage treatment plants are highly developed and efficient for offshore application. Our proven capability ensures product performance above and beyond legislative guidelines.

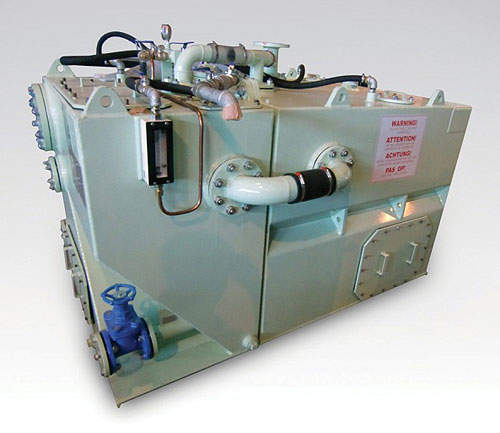

Optimised for treating black and grey wastewater flows and suitable for conventional gravity and vacuum fed collection systems, all plants in our STA-C and ST-C range are controlled automatically resulting in safe unattended operation, reducing maintenance requirements / man hours and operating costs long-term. Systems are compact and modular in design, suitable for between deck installations, and are adaptable to customer new build requirements / specifications.

Replacement wastewater treatment

Hamworthy also supplies a STA-C retrofit range suitable for replacement installations. The retrofit range is specifically designed to reduce the cost of installing sewage treatment equipment into existing rigs / platforms. Each size in the retrofit range is built up from three separate water tight tanks connected by external piping, aiding installation. The dimensions of each component tank has been arranged to permit its transportation through standard rig / platform access ways.

Our retrofit range is specified, installed and commissioned working in close cooperation with the world’s leading waste collection companies, ensuring smooth installation and reduced technical risk.

Hamworthy is able to assist in offering a complete system survey, reviewing current sewage treatment installations, providing an easy solution were required with considerable installation benefits for retrofit customers.

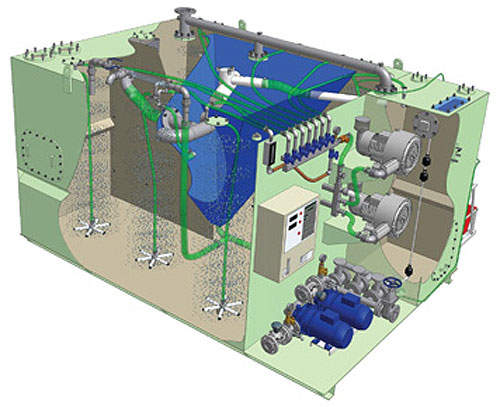

Membrane bioreactor (MBR) technology

Hamworthy’s membrane bioreactor (MBR) technology is an advanced black and grey wastewater treatment process designed to satisfy the most stringent effluent standards, meeting the challenge of protecting the environment head-on.

The innovative MBR system is an evolution of our proven sewage treatment technology. Through biological degradation and membrane separation, our systems can produce the highest quality discharge, exceeding international standards without the addition or generation of chemicals hazardous to the maritime or rig / platform environment.

Utilising side-stream cross-flow membrane configuration, each module contains large numbers of ultra filtration membrane tubes designed to achieve very high permeate production under cross-flow scouring velocity with minimal risk of blockages.

Hamworthy’s MBR technology achieved outstanding performance in Alaska under the scrutiny of the local authority, USCG and USEPA studies over the past seasons, meeting a permeate quality that exceeds the most stringent coliform standards.

Complete offshore wastewater offerings

Hamworthy Water System can offer complete system supply and a range of wastewater products, including sewage treatment systems, membrane bioreactors, vacuum collection systems, toilets, macerators, grease traps, holding tanks and transfer pumps, ensuring a reduced technical risk.

Hamworthy Services

Hamworthy Services offers a global network with a growing service resource of qualified engineers. Located in key strategic centres around the world and supported by our extensive network of agents and distributors in 70 countries, Hamworthy is well-placed to deliver. We build strong and reliable relationships with all our customers. Our through life system / technical support, and prompt service and delivery of replacement parts ensures the long-term safety and economy of your operations, minimising equipment downtime.