Enwa is among the leading manufacturers of water treatment equipment for the maritime oil and gas industry. We manufacture and supply a wide range of reverse osmosis (RO) freshwater maker systems together with pre and post-treatment for potable / drinking water.

Enwa is the manufacturer of the patented, chemical-free water conditioner, EMM by EnwaMatic®, for freshwater-based, closed loop, cooling and heating systems for engines and HVAC. The EMM by EnwaMatic is an environmentally friendly and chemical-free automatic unit that inhibits corrosion, controls scaling, filters water to less than 10µm, restricts bacteria growth and removes sludge, gas and oxygen from the water circuit. This is achieved by treating the water in a side stream filter regulating the water pH, alkalinity and hardness.

Enwa also manufactures the patented chemical-free bacteriological barrier, Enwa BIN-X®. The Enwa BIN-X is a patented cost-effective water treatment system used for removal of particles and bacteria such as Legionella and E-coli from potable / drinking water, offering maximum security against such epidemics. With the Enwa BIN-X® this can be achieved with a moderate level of investment.

Our systems are delivered worldwide, while our commissioning and training programme ensures first-class operation. We supply turnkey fresh water treatment solutions to some of the most demanding environments in the world. Our technology is both environmentally friendly and energy efficient.

Water conditioner for oil and gas applications

Enwa maritime water treatment (EMM by EnwaMatic) provides the user with a comprehensive water treatment system. EMM is designed to inhibit corrosion, control scaling, filter water to less than 10µm, restrict bacteria growth and remove sludge, gas and oxygen from the system water loop. This is achieved by treating the water in a side stream filter, regulating the water pH, alkalinity and hardness.

Environmentally friendly and self-contained, EMM does not require the use of hazardous chemicals or the critical exposure of employees during service and maintenance work. This has an obvious positive effect on both the environment and the HSE conditions for the employees operating and performing maintenance. There is also a financial upside as the requirements for chemicals are removed, and as a result of this the maintenance requirements are reduced significantly. The EMM by EnwaMatic is fully automatic and requires only minimal maintenance.

Enwa was one of the nominees of the ONS 2006 Innovation Awards with this product.

Reverse osmosis (RO) fresh water maker / desalination systems

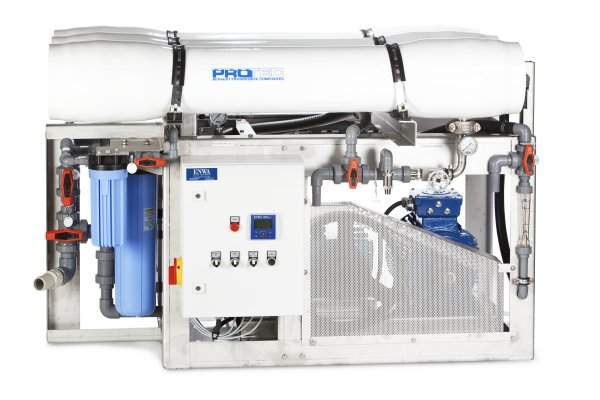

Enwa develops and produces desalination units based on reverse osmosis (RO). Used on ships, yachts, offshore vessels, drilling rigs and platforms throughout the world, RO units from Enwa are also used in numerous industrial applications such as refineries and terminals.

Enwa desalination units are cost-effective and known for their reliability and user-friendliness. Our container-based solutions are robust and compact. We manufacture standard off-the-shelf units of up to 100m³/d, larger units upon request. To date, Enwa has delivered over 1,500 RO systems.

Chemical-free bacteriological barrier

In drinking water systems, water is exposed to conditions that create a possible hazard to its quality. This can create danger to health and even life-threatening situations such as outbreaks of Legionella and E-Coli related epidemics.

Enwa BIN-X is a patented, cost-effective water treatment system used for removal of particles and bacteria such as Legionella and E-coli from potable water/drinking water, offering maximum security against such epidemics. With the Enwa BIN-X this can be achieved with a moderate level of investments.

Enwa was one of the nominees of the ONS 2006 Innovation Awards with this product.