CETCO Oilfield Services water treatment division specializes in the removal of hydrocarbons, solids, toxic materials, and other contaminants from oilfield wastewater streams produced during oil and gas operations, transportation, and storage. Working on applications such as:

- Produced water treatment and polishing

- Well stimulations and acid flow backs

- Pipeline maintenance

- Decommissioning waste waters

- Initial well flow backs/completions

- Workover fluids and coiled tubing job

- Brine filtration and recycling

- Heating / cooling medium treatment

FlexTreat™ treatment of problematic fluids

FlexTreat is a system which combines conventional water treatment technologies and proprietary media to effectively process problematic fluids of wide ranging and uncertain composition. Waste water from a variety of different sources which contains solids, crude oil, drilling waste and production chemicals is treated to stringent discharge criteria.

CrudeSorb® proprietary adsorption media for water treatment and polishing

CrudeSorb is a proprietary adsorption media based on resin, polymer and clay chemistry, which has proven to be extremely efficient at removing oil, grease and soluble organics from water systems. CrudeSorb has been developed for the treatment and polishing of various waste systems and is packaged in radial flow non-ferrous canisters, which allow for a quick media change outs.

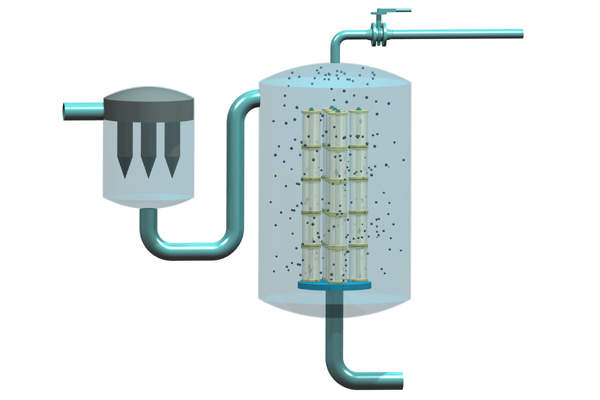

Hi-Flow® polymeric media for water treatment at high flow rates

Hi-Flow is a new generation polymeric media which removes free oil and grease from water by utilizing a combination of mechanisms. The majority of the oil is removed by merging of the oil droplets but the media also has some absorption and adsorption properties. Hi-Flow is a simple and robust system that can treat high rates of free oil in water, allowing the operator to discharge fluid back into the environment in compliance with legislative requirements.

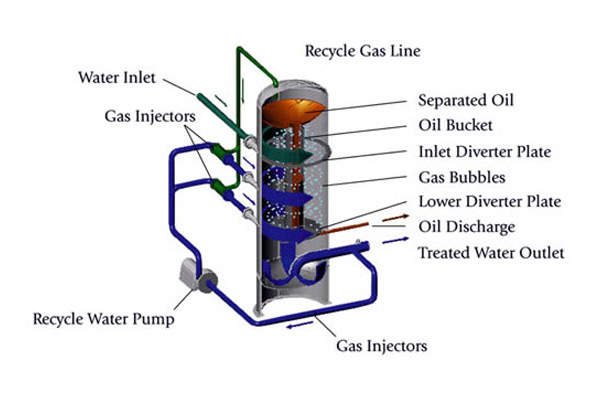

CrudeSep® produced water treatment separation technology

CrudeSep is a vertical column vessel, used for produced water treatment, typically operating near atmospheric pressure. Gravity oil separation is enhanced by induced gas floatation and cyclonic motion, which create centrifugal forces to separate fluids of dissimilar specific gravity. Operating the units in series configuration delivers excellent efficiency in the reduction of OIW levels.

Case study 1 – Hi-Flow® produced water treatment delivers outstanding results for Taylor Energy

Taylor Energy is utilizing Hi-Flow technology to increase oil and gas production in a field where the existing facility was at capacity with the amount of produced water it could handle.

For Taylor Energy, the Hi-Flow process was successful in removing more than 99% of the oil from the water.

“This new technology reduces processing, time and cost, while also saving us deck space due to its small footprint,” says Taylor Energy’s project engineer, Theo Gibson. “It is also very environmentally friendly, producing a small carbon footprint and reducing the volume of chemicals used within the process.”

Taylor Energy will also experience long-term benefits from using the Hi-Flow process, since its long lasting Hi-Flow media reduces operating costs.

Case study 2 – CrudeSorb® clean up of oily waste water for Chevron

CETCO Oilfield Services exceeded expectations during another successful clean up operation of oily water streams onboard the Stena Spey rig, as part of a series of well intervention and clean-up operations in Chevron’s Strathspey and Captain Fields.

The two part operation, which utilised CETCO’s CrudeSorb technology, exceeded client expectations with reduced operating time and lower discharge rates than the legal limits set by BERR.

CETCO also treated fluids which had come directly from secondary operations within the well. These included all wash water, including that from the solids washing operations and all other water from equipment involved.