The newly merged Camfil Farr group is a leading supplier of heavy-duty filtration and noise control equipment for major power generating and offshore operators worldwide.

For over 30 years, Industrifilter has been known as a strong and reliable global supplier of filtration and acoustic packages for turbomachinery. Camfil, a worldwide air filter supplier located in Trosa, Sweden, acquired Industrifilter in 1998. In 2000, Camfil acquired the US company Farr Co. building a world leading air filtration group.

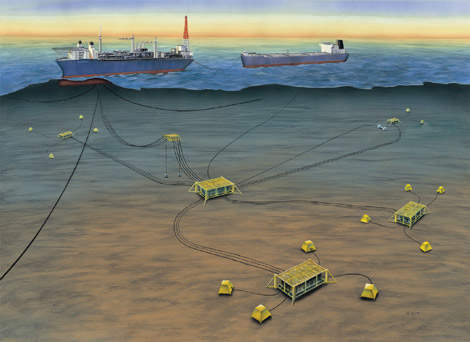

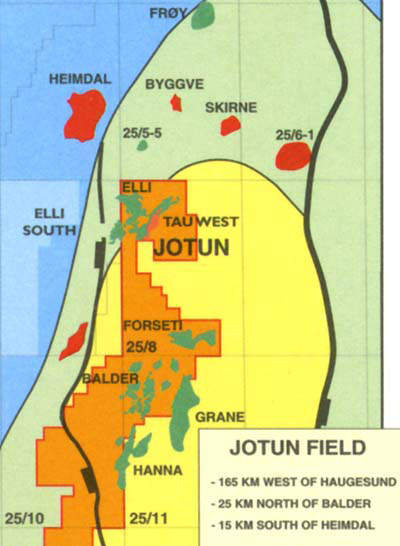

OFFSHORE FILTER SYSTEMS

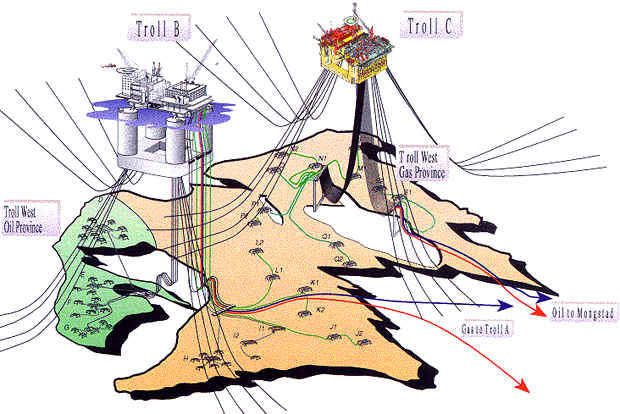

The supply of filtered combustion and ventilation air offshore is a technical challenge. In addition to the marine environment, with salt particles in dry and wet phases, there are also industrial contaminants, such as hydrocarbons, cement, shot-blast sand, drilling mud, etc. In this environment, reliability is absolutely essential. Offshore filter systems are designed to clean process and ventilation air on stationary and floating platform installations. High-efficiency filters clean the air and help ensure the reliability, efficiency and operating economy of the process.

Camfil Farr supply filters exclusively developed for rotating machinery. They are suitable for high humidity conditions, resistant to vibrations and pulsations, efficient across a broad range and have high dust holding capacities.

We have two different types of filter systems for offshore application. They are based on two different principles in order to cope with salt in dry and wet phase.

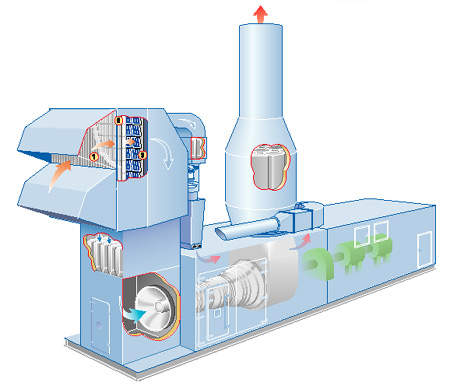

MEDIUM VELOCITY BARRIER SYSTEM

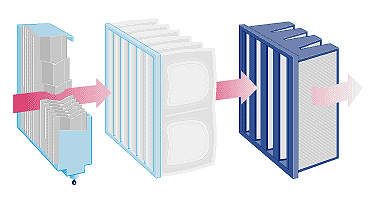

The Medium Velocity Barrier System offers high filtration efficiency (class F9, EN 779) and low-pressure drop. It is a non-entraining filter system so it eliminates droplets from being carried into the airstream. The final stage filter CamGT has been developed for use under high humidity conditions. Face velocity is 2.5m/s to 3.9m/s. Air cleaning takes place in three stages:

Weather Protection: a weather hood prevents wet snow and large droplets from entering the air intake. A CamVane droplet separator (a vertical vane medium velocity inertial vane separator) removes the small droplets from the air stream and provides with its high water handling capacity an optimum weather protection.

Prefilter / Coalescer: the prefilter / coalescer, normally in one combined stage, of type Hi-Cap G4 or 30/30WR, is a prefilter with synthetic filtermedia. Beside being a prefilter with high dust holding capacity (DHC) for long filter life, it also act as a coalescer, removing the smallest droplets which are not knocked-out by the droplet separator.

Final Filter: the CamGT is developed for offshore and coastal installations. It has high efficiency, low pressure drop and maintained performance in wet conditions.

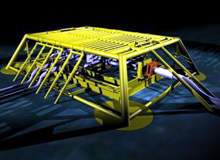

HIGH VELOCITY BAGFILTER SYSTEM

Weather Protection: a weather hood prevents wet snow and large droplets from entering the air intake. A high velocity droplet separator (a high velocity inertial vane separator) removes small droplets from the air stream and provides optimum weather protection with its high water handling capacity.

Filter Stage: this uses a bagfilter of F6/F7 efficiency with synthetic media and reinforced for high velocity. Depending on dust load and filter performance (dust holding capacity) the bagfilter can be protected by a prefilter.

Final Stage: a high velocity droplet separator (a high velocity inertial vane separator) removes droplets which carry over from the filter stage.

Efficiency is limited by high velocity systems, allowing the sub-micron particles to penetrate. The high velocity system is therefore only recommended when size constraints make it impossible to install a medium velocity system or when high efficiency on small particulate is of less importance. The risk of re-entrainment of dry deposits on the final stage must also be considered.

OTHER AIR INLETS FOR OFFSHORE USE

With our knowledge of offshore conditions and air filtration know-how, we can supply complete air inlet and acoustic systems, for example, for HVAC-installations, diesel engines, power generators and compressors.