AREVA NP Uddcomb, a leader in high-tech engineering and welding technology, offers technical solutions for increased performance, availability and safety at our customers’ facilities. Our assignments cover everything from small consultancy services up to large projects running for several years, both nationally in Sweden and internationally.

Cladding / overlay welding for pressure-vessel repair, pipe and tube upgrade and corrosion protection

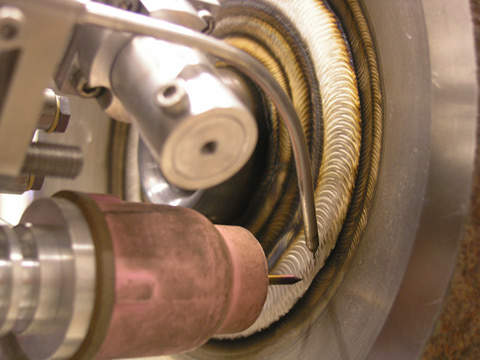

With overlay welding, AREVA NP Uddcomb is in a position to considerably improve corrosion protection in process equipment through its own, in-house developed methods: Uddcomb Method™ and Opticro™. These provide a permanent solution.

The methods are used in process industries for corrosion protection of pressure vessels or other equipment/components. The methods are also used in the power industry for corrosion protection of tubes in boilers of different types.

The methods are flexible and can be adjusted to the present corrosion conditions and the geometries of the equipment in question. Twin-torch technology, programmable system architecture, and multi-system capability ensure that we have the highest quality standards.

The Uddcomb Method is a proven technology for the repair and upgrade of pressure and process vessels. We understand the need for permanent repair solutions that are delivered on time and to budget.

Welding development, manufacture, repair and consultancy

Advanced welding is a key element in most of our operations. We undertake weld repairs in challenging materials; develop weld repair concepts; manufacture welded products; and provide consultancy services.

Mechanized weld equipment for MIG/MAG and TIG

We have mechanized weld equipment for MIG/MAG and TIG. We can adapt our equipment for specific applications, e.g. weld operations in narrow areas or remote control with a camera.

Our equipment and weld technology provide flexibility, productivity and top-quality welding. Application areas include:

- Cladding / weld overlay of pipe flowlines

- Development of a weld repair concept for cracks in difficult materials, where we also perform the weld repair operation with our qualified weld engineers, project managers and welders

- Weld overlay of nozzles or other components in all combinations of materials, including in difficult-to-access places like oil platforms

- Welding of components for the process industry or industries with similarly high demands on welding and documentation

Welding of customised components

A background as a pressure vessel manufacturer has provided AREVA NP Uddcomb with a wide knowledge of materials and welding technology. We manufacture and design components on the basis of the client’s wishes, including:

- Pressure vessels

- Subsea cable joints

- Heavy equipment

- Filters

- Piping

- Heat exchangers

- External and internal weld overlay tubes

- Advanced welded components

All production takes place in our own premises. Welding work is certified in accordance with SS-EN ISO 3834-2:2005.

Welding qualification and consultation

We provide qualification of welding procedures and consultation on complete solutions for advanced weld applications; our accredited laboratory provides efficient support to these processes.

Selection of base and filler material; development of weld systems; welding procedures and weld qualification programs; and examination and analyses of defects associated to welding are also among our capabilities.

Project management, analysis, calculation, mechanical design, and weld technology

Our competencies are in project management, analyses, calculation, mechanical design, and weld technology. We deal mainly with process systems and mechanical engineering, where we often offer a turnkey service.

We are actively seeking strategic partnership with key customers. Our operations are signified by top-of-the-line competence, reliable delivery and cost-effective solutions.