SAFETYTAINER safety modules are designed to ensure that equipment is protected in areas where explosive atmospheres can be caused by flammable gas, vapour, mist or combustible dust. The company’s modules, built according to ATEX directives, are designed for use on offshore production platforms, drilling rigs and in refineries and SEVESO areas.

SAFETYTAINER’s new integration of equipment and functionalities of ATEX safety (IEFS) groups supply ATEX protection functionalities to any new or existing shelter, after certification of the complete system. Each individual shelter is designed according to the hazard level on-site.

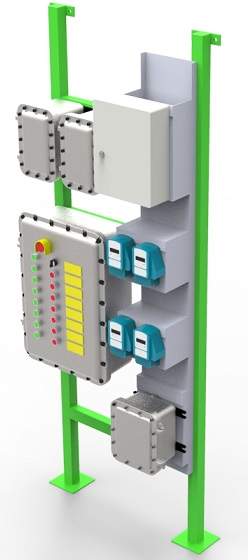

Offshore safety modules

The company’s IEFS group consists of the following.

Fresh air (outside the shelter):

- Fresh air drawing within safe zone

- Ventilation and pressurisation in normal operation

- Sweeping when ATEX safety commissioning

- Fresh air filtration through high efficiency filters (lack of corrosive particles for offshore implementation and onshore installations)

Command control skid (inside the shelter):

- Control of fresh air flow and overpressure at 25Pa

- Control of ATEX active safety

- Control of protected installation safety

- Management of possible air lock

- In case of fire or gas alarm, automatic safety layouts arrangements

- Local and remote alarms activation

ATEX certification in two steps (zone 1)

Shelter’s project (first step):

- After design file approval by customer, the file is submitted to certification body for technical review

Shelter’s completion (second step):

- Certification test preparation

- Test procedure implementation

- Issue of certificate of conformity by certification body

ATEX self-certification in zone two

Self-certification is done by the manufacturer, which will issue a complete file with all documents able to show the accordance with all ATEX standards.

Additional equipment for ATEX zones:

- Air conditioning units (power adjusted to external and internal thermal intakes)

- Fire detection and protection, volume confinement to be protected

- Lighting, emergency lighting, sockets, etc.