Texas-based PetroHab is a leading provider of Hot Work Safety Enclosures (HWSE) for worldwide oil and gas industry, also known as ‘Petro-Habitats’.

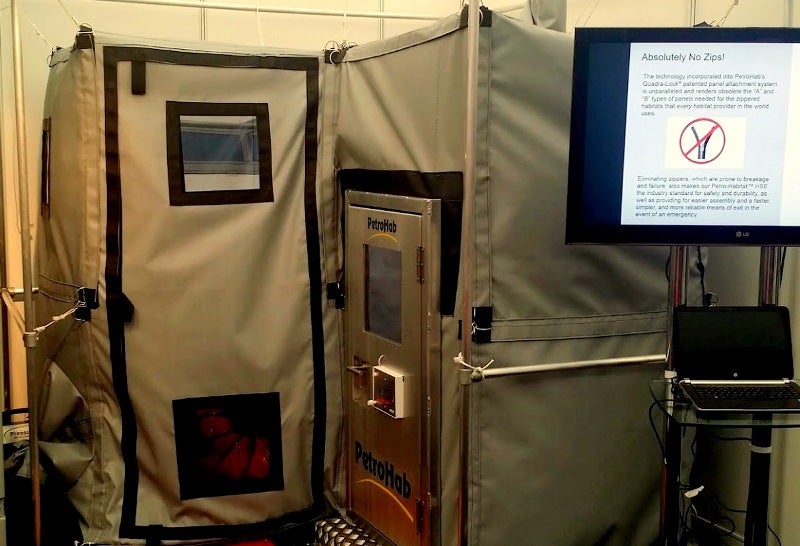

That leadership position was buttressed in December of 2016 when the United States Patent and Trademark Office granted PetroHab United States Patent No. 9,517,609 on its Quadra-Lock: the one-of-a-kind, panel interlocking technology which has effectively rendered all of its competitors’ zippered and trouble-prone habitat panels practically obsolete.

No longer needing an A-type panel and a B-type panel in order to zip two panels together, the Quadra-Lock 1m-by-1m panels are all standard and completely interchangeable, boasting incredibly fast assembly and disassembly times.

Moreover, like the powerful in-house manufactured 5HP pneumatic intrinsically safe blower, which is capable of throttling air up to a flow of 7,000cfm, all of the panels making up every Petro-Habitat are also proudly made in the USA.

Whereas most, if not all, of PetroHab’s competitors adhere to a ‘lease only’ model for the provision of their habitats, PetroHab realized that in these times of depressed oil prices, selling such products to customers, and then training and certifying their personnel on the assembly, disassembly and maintenance of the Petro-Habitats, makes far better economic sense to an end user.

In fact, in what an average user spends on leasing a habitat for approximately 30 days, that customer can actually own a Petro-Habitat, thereby avoiding both personnel and equipment mobilisation and demobilisation fees, reducing the ever-problematic Persons on Board (POB) issue, and using our Petro-Habitats whenever they please without having to pay stand-by rates for times of non-use.

All HWSEs are designed to contain the by-products of hot work operations, such as sparks and molten material.

Since our Petro-Habitats are sealed and pressurised, they deny the ingress of hydrocarbons, thus allowing hot work operations to be safely executed within the HWSE even when the surrounding process plant or equipment is fully operational.

This is due to the positive pressure environment created in the Petro-Habitat (from the blower that intakes air from an unclassified area) coupled with the 1,000°F continuous heat resistance offered by the ANSI / FM 4950 certified premium silicone coated fiberglass materials from which each Petro-Habitat panel is made.

Meanwhile, the floor tiles that are used to cover the flooring of the Petro-Habitats is made from a silicone coated, 75-ounce-per-square-yard vermiculite fiberglass cloth that is rated up to 1,500°F of continuous heat resistance.

Although our Petro-Habitats are primarily used in offshore platform settings, they can be utilised in refinery and industrial plant settings as well as any type of industrial layout where hot work is conducted in the vicinity of potential flammables.

Since sparks and molten materials from hot work activities such as welding, grinding and cutting can be scattered more than 35ft, it comes as no surprise that hot work is a leading cause of industrial fires, consistently ranking in the top five causes of fires across all industries.

As such, safety professionals are constantly challenged to ensure the health and safety of workers conducting hot work operations.

The win-win situation enjoyed by users of Petro-Habitats is that in seeking to enhance the safety of their workers, PetroHab’s clients gain the added benefit of guarding against the destruction and / or replacement of their companies’ physical assets.