PetroHab™ provides hot work safety enclosures (HWSE) systems and automatic shutdown systems to the oil and gas industry.

Safety compartments for the offshore sector

PetroHab’s HWSE products are designed to cater to varying onshore and offshore applications and include:

- The Petro-Habitat™ pressurised HWSE: suitable for use in classified hazardous areas and is used in conjunction with PetroHab’s Safe-Stop™ modular shutdown systems (MSDS) or Safe-Work™ modular control systems (MCS)

- The Petro-Lite™: a closed or open-toon pipelines from potentially hazardous environmental conditionsp HWSE that is ideal for applications at refineries and industrial plants, such as turnarounds or shutdowns

- The Petro-Shield™: a mobile enclosure that contains ignition sources generated by hot work and protects personnel working

Customizable hot work safety enclosures

PetroHab’s fully customizable and scalable Petro-Habitat HWSEs are constructed with interchangeable 1m² interlocking panels that are manufactured to exacting standards.

Made from a premium silicone-coated fiberglass cloth, the Petro-Habitat’s panels withstand continuous temperatures of up to 1,000°F (540°C), and meet the fire resistance and ignition prevention standards set by ANSI/FM 4950. To further ensure uncompromised strength and durability, the panels are stitched with virtually inflammable, military grade Kevlar® thread.

The robust 1m² window panels are also paired with easily replaceable Makrolon® polycarbonate window panes, which have ultimate shear tensile strength of approximately 10,000psi.

Flexible silicon-coated vermiculite fiberglass tiles cover the HWSE floor and are capable of resisting temperatures of up to 1,500°F (815°C).

PetroHab’s patented Quadra-Lock® panel attachment system allows unlimited configurations and promotes a high level of modularity.

The Petro-Habitat provides easy assembly and disassembly, as well as a faster, simpler and reliable escape method in the event of an emergency.

The Petro-Lite portable HWSE uses PetroHab’s proprietary and patented Quadra-Lock® technology to securely attach all of its panels to each other, each of which is made of silicone-coated, ANSI/FM 4950 certified fiberglass cloth.

The mobile and modular Petro-Shield HWSE is suitable for operations such as pipeline welding, wellhead testing, pipe coating and inspection, and hydro-testing. Its tubular frame is constructed from 6061 aluminum pipe and its length is expandable in 4ft increments.

Automatic shutdown systems for Zone 1 areas

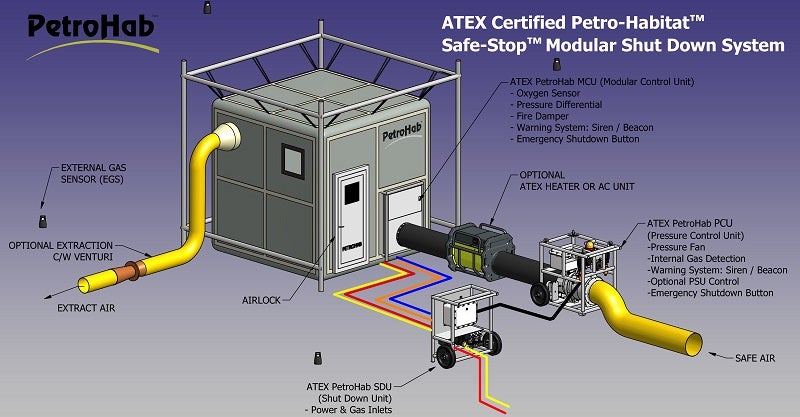

The PetroHab Safe-Stop MSDS works with the Petro-Habitat HWSE to provide safety whenever hot work is conducted near potential flammables, such as in Zone 1 rated areas.

By continuously monitoring the pressure inside the Petro-Habitat HWSE, the Safe-Stop MSDS enhances the Petro-Habitat’s safety by only allowing hot work to be performed within the HWSE at the correct balance of air pressure inside and outside the unit. This creates a ‘positive pressure environment’ within the Petro-Habitat, which prevents unwanted flammable gases from entering the enclosure, allowing hot work to be safely performed without the need to shut down the surrounding facility.

PetroHab’s integrated, ATEX certified Safe-Stop MSDS is a compact and lightweight alternative to older automatic shutdown systems, which almost universally require an extensive amount of hardware, ducting, and cabling.

While monitoring the pressure within the Petro-Habitat, the Safe-Stop MSDS also detects various gases both inside and outside the HWSE.

The Safe-Stop system consists of three main components; the Modular Control Unit (MCU), the Pressure Control Unit (PCU), and the Shut Down Unit (SDU). The MCU is incorporated into one of the wall panels of the Petro-Habitat HWSE, while the operating airflow inlet, fire damper, and oxygen sensor are housed in the compact MCU, maximizing working space within the habitat. A pressure differential sensor, and siren & beacon warning system, are also part of the MCU, while the PCU contains the main control unit, H2S & methane gas detection, a fan to pressurize the habitat, as well as an additional siren and beacon.

Upon detecting either a loss of pressure, or high or low oxygen levels inside the enclosure, the ATEX Zone 1 Safe-Stop MSDS will automatically shut down the hot work operations, while keeping the intake blower running in order to pressurize the Petro-Habitat. Should any hazardous gases be detected in the feed to the PCU, the Safe-Stop MSDS will shut down both the hot work operations and the flow of air.

Modular control system for gas detection applications

Petro-Hab’s economical ATEX certified Safe-Work™ Modular Control System (MCS) provides a safe work environment within Zone 2 rated hazardous locations. This system is integrated into the Petro-Habitat in the same way as the ATEX Zone 1 rated system, but eliminates the extra services, and costs required for Zone 1 rated areas.

About PetroHab

PetroHab aims to be the world’s leading provider of HWSEs and related automatic shutdown systems, which are both nationally and internationally recognized for their quality, durability and safety.

Headquartered in Houston, Texas, USA, PetroHab has recently established PetroHab UK in Dundee, Scotland, and collaborated with Al-Farah Contracting & General Transport Establishment in Abu Dhabi to cater to the Middle East region.

PetroHab also has strong local connections in Brazil, Nigeria, Angola, Malaysia, Indonesia and Thailand.

Depending on its customers’ requirements, PetroHab can fully train and certify personnel either on-site or at its state-of-the-art training facilities in Dundee or Houston.