Torqueflow-Sydex is a sister company of progressing cavity pump manufacturer Sydex. The company has developed an extensive range of high-quality and cost-effective progressing cavity pumps, also known as helical rotor pumps, PC pumps and progressive cavity pumps, which are today used extensively all over the world.

By being able to provide state-of-the-art market-driven products, flexibility in providing customer-focused solutions and unparalleled levels of service, we are now one of the fastest growing progressing cavity pump manufacturers in the world. Our factory is fully certified to ISO 9001:2000.

Progressing cavity positive-displacement pumps

Torqueflow Sydex’s range of cavity positive-displacement pumps is extensive and includes the original Moineau pump design with the stator bonded into a steel tube. Pumps can be supplied in accordance with API 676 with seals to API 682 where specified.

Progressing cavity pumps are widely used in the offshore oil and gas industry. Applications include:

- Offshore oil and gas drilling platforms, fixed and floating (FPSOs)

- Flare knock-out drums

- Low NPSH applications (high suction lift applications)

- Crude oil processing

- Drilling mud

- Waste oil

- Oil-water separation

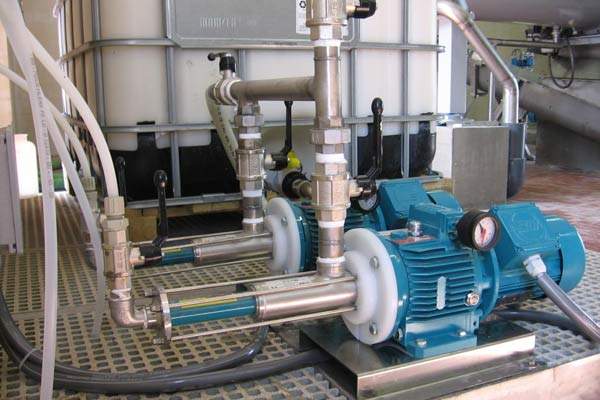

Horizontal progressing cavity pumps

The ‘K’ range of horizontal progressing cavity pumps is the core offering from Torqueflow-Sydex. The range is available in a wide range of materials, including cast iron, and stainless steel 304 and 316 through to duplex steel (SAF 2205), to suit highly corrosive and difficult applications such as high salinity laden liquids.

Vertical progressing cavity pumps

The highly versatile vertical ‘E’ range pumps are also known as barrel emptying, vertical sump or semi-submersible pumps. Vertical pumps are suitable for numerous applications within the oil and gas, and chemical industries where high suction lifts (low NPSHa) are an issue. The pumps can be directly mounted inside a tank, keeping the motor safe from any potentially hazardous and/or corrosive environments.

The ‘E’ range of pumps is available in a wide range of materials, including cast iron, and stainless steel 304 and 316 through to duplex steel (SAF 2205), to suit highly corrosive and difficult applications such as high salinity laden liquids. Other materials including plastic are available upon request.

Progressing cavity pumps

The ‘M’ range progressing cavity pump series is designed specifically for dosing any kind of liquid. Dosing pumps feature reversible flow, an excellent self-priming rate and low-shear pulsation-free pumping. Accuracy, which is often extremely important in this application, can be maintained at a maximum variation of ±1%.

This range is constructed in aisi 316 stainless steel with optional stator materials, including viton, EPDM and nitrile (perbunan).

Progressing cavity pump principles

The basic principle of a progressing cavity is deceptively simple. A single external helix (rotor) oscillates within a stationary double internal helix (stator). This forms a series of cavities 180° apart. As the rotor oscillates, these cavities gently convey liquid from the low-pressure suction end to the high-pressure discharge end.

Pressure is maintained by the contact point between the rotor and stator (seal line). The flow capability is determined by the size of the cavities (diameter of stator and rotor), and the pressure is determined by the number of stages (length of rotor and stator).

Progressing cavity pumps are extremely effective at handling solids laden, and/or viscous / non-Newtonian liquids. Careful selection and application expertise is Torqueflow-Sydex’s prerequisites. This, combined with a principle of ‘quality through service’, ensures we maintain the most exacting standards.