Sulzer has been contracted as the pumps provider for the critical liquids removal system of the INPEX-operated Ichthys liquefied natural gas (LNG) project in September 2014.

The pumps will be installed on the offshore central processing facility (CPF). Sulzer will deliver six large API 610 (ISO 13709) Barrel Casing Pump sets in 2015.

The scope of supply of the pumps includes the six pump skids with electric motors and complex seal systems, which are being manufactured, packaged, and tested in the Sulzer state-of-the-art test facility in Bruchsal, Germany.

The installation of the pumps into the module will also be supervised by our experts in the Asia-Pacific region, with future offshore support from Sulzer Australia.

The Sulzer pump model GSG was chosen to meet very challenging mechanical and process requirements by INPEX to stringent project specifications. Some of the most critical requirements are very high-suction pressure design with four operating cases on different liquids with various densities. The pumps are suitable for the future duties with only a cartridge retrofit to a fully staged pump and no change to the fixed speed electric motor. This gives the advantage of minimal downtime and ease of pump retrofit offshore.

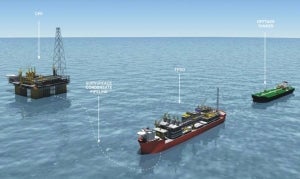

The processing on the CPF will separate the gas from liquids. The Sulzer pumps will transport the liquids from the CPF to the FPSO (floating production storage and offloading unit), stationed about 3.5km away. Sulzer has previously received an award from INPEX for 69 API 610 pumps for the FPSO; the largest of these pumps are manufactured and tested in our factory in Germany.

For more information, please contact Sulzer.