RMI manufactures high-pressure reciprocating pumps for a vast range of applications and markets.

It has expertise in many sectors, with complex installations ranging from underground coal mine pump stations to critical applications such as umbilical pipe testing for the offshore oil and gas industry. Understanding the diverse nature of and the requirements for these markets has been crucial to the company’s success over the years. Its modular design allows RMI to manufacture systems to customers’ specifications and enables the company’s design team to collaborate with clients to provide the ideal solution, dependent on environmental and operating conditions.

Trimax reciprocating plungers

Trimax S50 to S350 Pumps are reciprocating plungers with three rams. The ‘S’ range of plunger pumps forms the core of RMI pumping systems. All pumps are fitted with a robust, fully supported crankshaft with conrods assembled with lead bronze and big and small end bearings. Extremely high wear-resistant solid ceramic plungers, combined with kevlar fibre seals, provide long-lasting high-pressure sealing. Trimax pump duties range from 46l/min to 670l/min at 148 bar to 1,000 bar (50Hz speed).

All pumps undergo a rigorous testing programme prior to dispatch, including oil temperature and pressure checks plus vibration monitoring, as well as the normal pump performance criteria. Pumps are under a continuous development programme to meet the most demanding operating conditions. Higher efficiency and reduced lifetime cost are key considerations in RMI’s design review process.

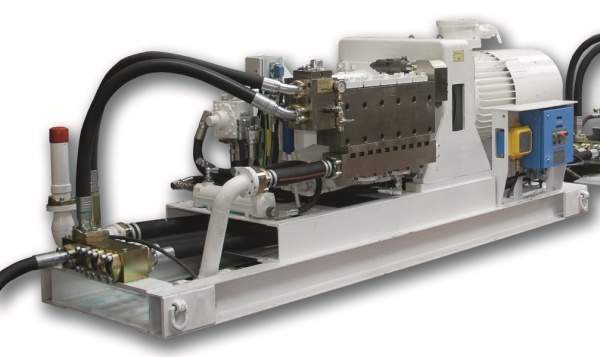

Quinmax S500 reciprocating plungers

The S500 is the latest addition to the very successful ‘S’ range. The key element of the S500 pump is its five-plunger design, which has several advantages over the more traditional three-plunger format. These include reduced forces on the crankshaft and associated bearings and a 40% reduction in fluid velocity per plunger. Reduced hydraulic noise and pressure pulses minimise the impact of surges on other critical items of equipment, increasing their life expectancy. Quinmax Pump Duties range from 340l/min to 1080l/min at 195 bar to 500 bar (50Hz speed).

Energy-efficient reciprocating pumps

An understanding of the complete process is critical and allows us to evaluate the running cycle of the pumps within the operating environment. To enable clients to realise maximum return on their investment, RMI evaluates the lifetime cost of the equipment, including original supply, servicing and running costs. All control methods are assessed and a full-life cost calculation submitted to the client.

Intelligent variable speed pumps have been supplied for many applications including heavy presses and steel pipe descale systems, with a calculated payback period of less than two years.

Reliable high-pressure pumps

RMI has established an enviable reputation for supplying the industrial market with some of the most reliable high-pressure reciprocating pumps available. Utilising the very latest technologies, coupled with the vast experience of its engineering team, RMI can deliver a system that will operate in the most extreme environments. Nickel plating is used to give longer life and better performance than stainless steel. Advanced ceramics improve surface hardness and reduce maintenance.

Control equipment

Pumps can be supplied as standalone products to be incorporated into the main process controls. However, to maximise system efficiencies, RMI will supply a complete control solution, including variable speed drives, automatic controls and all operating and health-monitoring functions, to ensure the equipment runs efficiently and fault free.

Quality controls

All RMI equipment is designed, manufactured and supplied in accordance with European ISO 9001 Quality Assurance accreditation, certified by Lloyd’s and governed by Quality Management Systems to provide and maintain client and user service. The company’s systems are regularly audited and updated to ensure full compliance.

Service and spares

All equipment is supplied with full operating and maintenance instructions. Full site training can be arranged to ensure site engineers can operate the equipment safely and can execute routine maintenance tasks. To support each product, however, RMI has fully equipped multiskilled service engineers who are ready to attend on-site whenever the case arises. RMI’s engineers are backed up by its many global agents, who have been trained to high standards on the company’s equipment and its operation.

RMI has a full range of spare pump modules and kits. Reducing maintenance downtime is critical and by utilising the company’s module approach, repairs can be carried out in record time. The need to hold or order large stocks of small intricate parts is removed, resulting in many associated savings in time and space. The pre-assembled kits come with a full manufacturer’s warranty and fitting instructions, providing additional reassurance.

Please use the enquiry form below and one of the RMI team will contact you to discuss your application need.