The PROCINT Group, a provider of pumps and pump packages, was founded by skilled people with extensive experience in the global sales and purchasing disciplines for the oil and gas industry. We deliver a full range of products and services that are required for building modular process modules for the on and offshore industry.

Plunger pump packages

PROCINT is the exclusive global sales office for S&K Supply pump packages for the oil and gas industry. All inquiries for pump packages outside of the US will be handled from our office in the Netherlands. Engineering, manufacturing and fabrication will be executed at S&K Supply in Texas, US, which is ISO 9001 certified.

S&K Supply is a well-known and specialist pump manufacturer in the oil and gas industry. We have provided pump packages to more than 18 FPSOs worldwide, and S&K has the capability to integrate engineering, manufacturing and fabrication in one single location.

PROCINT offers plunger pump packages from S&K Supply for the following applications:

- Well servicing

- Pigging

- De-scaling

- Hydrotesting / pipeline pressure testing

- Water injection

- Condensate transfer

- Crude oil transfer

- Methanol injection

- Chemical transfer for (petro) chemical and offshore industries

- Service pump packages

- CO2 transfer pump packages

- Other reciprocating pump packages

Besides S&K’s own pump design they have exclusive OEM arrangements with manufacturers such as Caterpillar, ABB and WEG. For the high-capacity packages we are partner with Gardner Denver. All this enables us to fabricate the package with competitive delivery time and prices. Therefore we are convinced that we can offer you high quality, well designed, specific pump packages at a competitive price for your future offshore as well as onshore projects.

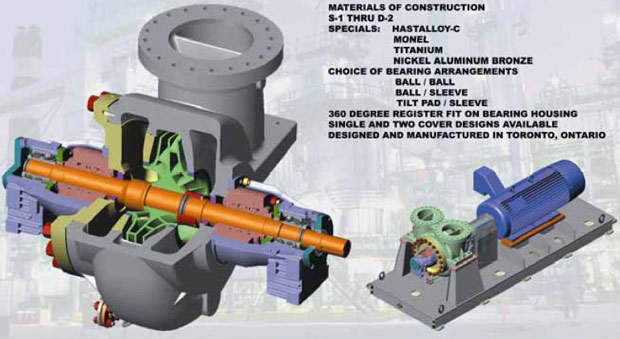

Centrifugal API 610 pumps

PROCINT supplies centrifugal API 610 pumps from CPC Pumps, a specialist in the design, manufacturing, testing and servicing of engineered, heavy duty process pumps. We also provide split single and multi-stage pumps for HC Process Industries, which meet the latest American Petroleum Institute specifications in API 610 and ASME codes.

CPC Pumps has extensive experience in the oil and gas sector, and operates in all sections of the hydrocarbon processing industry, from crude oil production and gas plants through to refining and petrochemical plants, as well as shipping and marketing terminals.

CPC Pumps can be successfully used in the following API applications:

- Crude oil transfer

- Pipeline boosting

- Liquid sulphur transfer

- Crude oil charging

- Special refinery services

- Hot asphalt transfer

- Vacuum tower bottoms

- Coke-crusher

- HF acid service

Heavy duty non-API services that employ CPC pumps include:

- Hot water boiler circulation

- LP boiler feed

- High pressure chemical services

- Gasification liquid transfer / charge

- Liquid sulphur disposal / transfer

- Mine dewatering

Metallurgy centrifugal pumps

All CPC pumps are manufactured in metallurgy to meet both service requirements and customer specifications. Pumps in API S-1, A-8 and specialty cast metal can be provided.

We are experienced in providing pumps made from duplex stainless steel, hastalloy, monel cladding, hard facing (TMT and Jet-Kote) titanium, ni-al-bronze and monel.

Hydraulic performance, hydrostatic pressure, vibration and noise pump testing

CPC Pumps’ hydraulic pump performance stand can test pump units up to 1,200hp at 1,800rpm or 1,200rpm. Hydrostatic testing can be performed using water or kerosene, up to 8,000psig. Variable frequency drives are available up to 150hp.

To ensure that CPC Pumps’ products meet our customers’ specifications and expectations, each unit must successfully pass tests in hydrostatic pressure, hydraulic performance, vibration and noise.

PROCINT is the exclusive representative in Europe for VME Process (VME), S&K Supply, ISLIP Flow Controls (IFC), RP Adams, Caloperm and represents S&W and CPC Pumps.