Geveke Pompen specialises in the engineering and packaging of a range pump and other packages for suppliers and operators in the oil and gas industry.

Geveke Pompen specialises in the engineering and packaging of a range pump and other packages for suppliers and operators in the oil and gas industry.

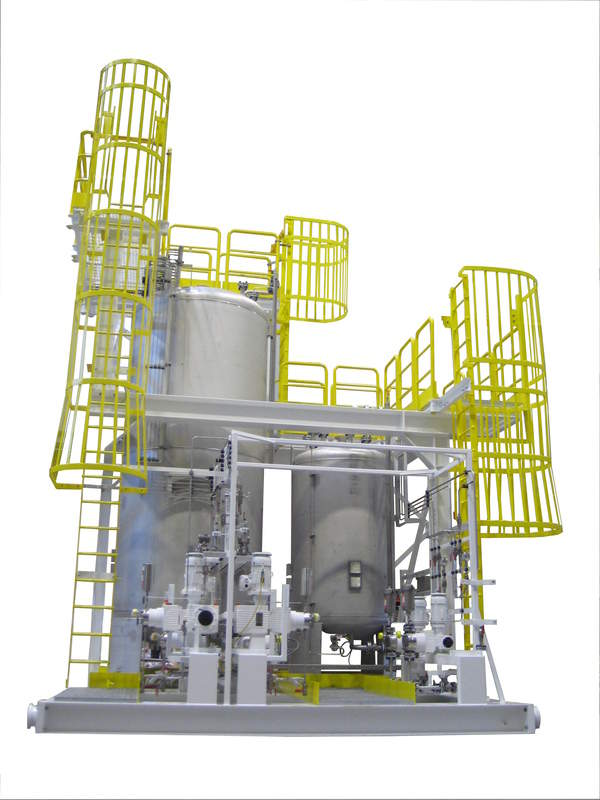

Integrated offshore packages

Geveke Pompen provides reliable and efficient solutions on time and within budget. All packages are designed as a fully integrated unit.

The packages are custom-made and are designed by the company’s experienced team of project engineers, based on customer specifications and compliant to specific requirements for FPSOs, TLPs, MOPUs and other onshore and offshore installations.

Geveke Pompen offers a wide range of packages, including:

- Chemical injection packages

- (M)ethanol injection packages

- LDHI injection packages

- IRCD distribution racks

- Chemical transfer packages

- Glycol injection packages

- Produced water injection packages

- Wellhead service pump packages

- Nitrogen generation packages

- Bottle racks

- TuTu and valve panels

- Eductor packages

- Instrument air packages

- Air dryer packages

- Gas booster skids

- Other specialised pump packages

Chemical injection packages

Geveke produces tailor-made chemical injection packages based on customer requirements and specifications, and are compliant to international standards.

Packages are available for onshore, offshore and floating productions facilities.

Welljead injection packages

Geveke supplies methanol injection packages, ethanol injection packages, LDHI injection packages and/or glycol injection packages.

These are similar to the chemical packages, however, normally pump flows are much higher. As these units are designed for injection in the wellheads the installed power may exceed several hundred kilowatts.

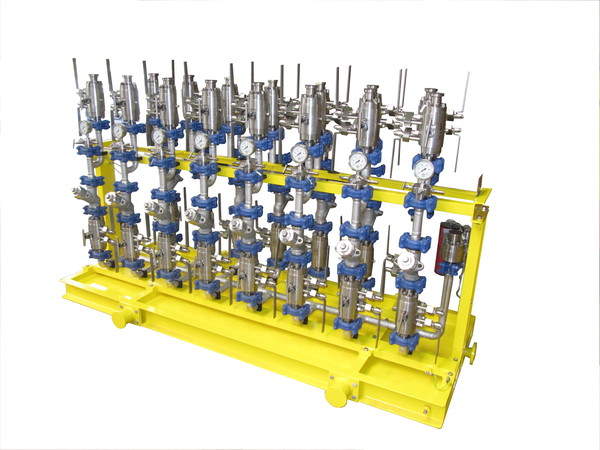

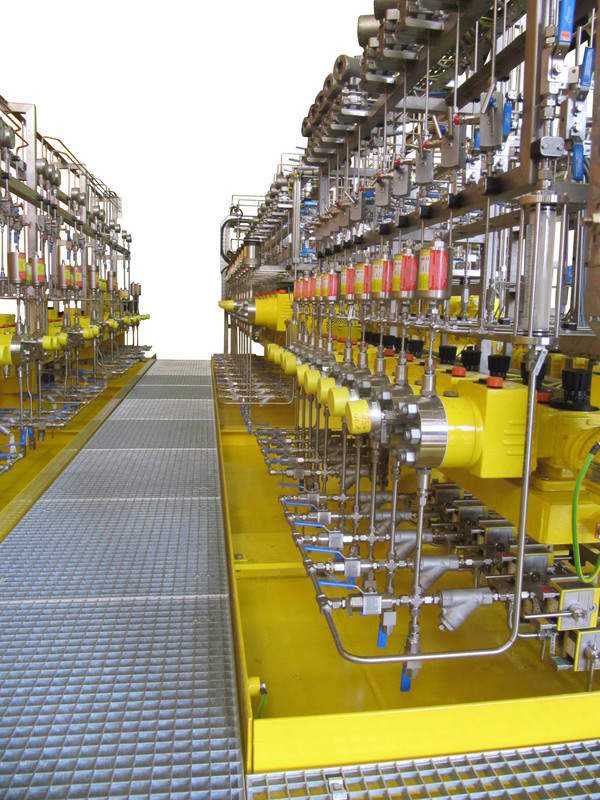

IRCD distribution racks

Injection rate control device (IRCD) distribution racks are used for multiple injection of chemicals. These systems reduce the number of rotating equipment, but maintain the possibility to inject chemicals in a large number of wells at the same time. Proper lay-out of IRCD’s and pumps is required, to avoid metering errors.

Chemical transfer packages

To fill tanks or transfer chemicals, specialised pumps and pump packages are available. Air-operated double diaphragm (AODD) pumps are used as these are low-cost, easy-to-perate and can be supplied as portable units.

Magnetic drive centrifugal pumps are also available.

Nitrogen-generation packages

Nitrogen-generation packages are used in the event of large capacities or at remote onshore and offshore locations. They are employed for a wide variety of applications to reduce fire or explosion risk or avoiding oxidation.

Eductor packages

Eductor packages may be implemented for evacuating gases, using a power gas to transport the waste gas to a flare or other location. The packages usually use large-diameter piping, valves, control valves and instrumentation.

Compressed air packages

Compressed air is used for both process and utility applications in many installations.

Based on the need for free air delivered at maximum working pressures, different compressor designs represent the optimum solution. The compressed air packages are based on different compressor types, such as centrifugal, rotary screw, rotary vane and piston.

Specialised pump packages

Geveke Pompen provides special pump packages for other applications. Their design is usually based on specific pumping principles to solve operational problems such as high-viscosities, sand content and corrosive or erosive properties.

Examples are packages based on sludge, screw, thermal oil, vane or disc pumps.

After-sales services and support

Geveke Pompen offers clients a 24/7 service, tuned to their requirements. The company has a service organisation for start-up and commissioning, preventive and corrective maintenance, including:

- Worldwide operation

- Experienced staff

- Workshops

- Test facilities

- Trouble shooting

- Training

- Parts supply

About Geveke Pompen

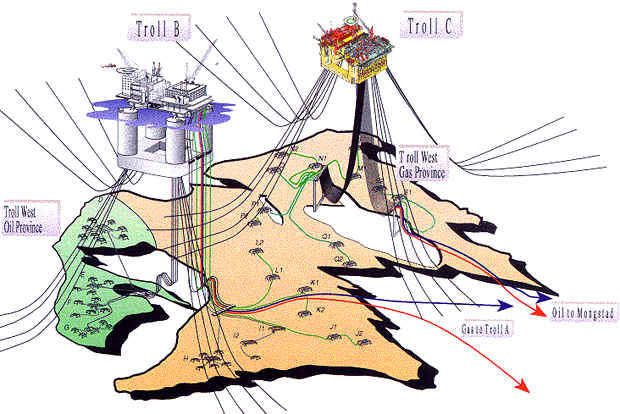

Since 1979, Geveke Pompen, a business unit of Geveke Werktuigbouw, a member of the Nikkiso group, has supplied thousands of pump packages to a wide range of clients worldwide.

For the FPSO market, Geveke Pompen’s first chemical and methanol injection packages were supplied in 1995. Since then many packages have been engineered and supplied. Clients include well known suppliers of leased FPSOs, major oil companies and various specialised module builders.

The company provides various industrial services, including:

- Consulting

- In-house engineering

- Procurement

- Project management

- Factory acceptance testing

- Start-up and commissioning

- Service and maintenance

A member of Achilles FPAL and TRACE, Geveke Pompen offers a number of management structures, including a quality assurance system according to ISO 9001:2015, and a VCA* system for safe operation of field mechanics and engineers onsite, both approved by Lloyds.