Airpack Nederland B.V. is a Dutch based ISO 9001:2000 certified company active all over the world, especially in Europe, the Middle and Far East. Our main products are air and gas compressor packages, air and gas dryer packages, and nitrogen generator packages.

Our packages are completely automatic after installation on your system. Calibration or mounting of instruments and stand-by equipment are not required. In addition to manufacturing, we also have worldwide operating maintenance specialists.

Airpack offers the following benefits to its customers:

- Technical support by high qualified engineers during both the bidding and order stages

- One responsible manufacturer for all components mounted on the skids

- Completely mounted and tested packages

- Design, manufacturing and tests according to the specifications of the customer and international standards

- Optimal interface between all components on the skid

- Our packages work completely automatically after installation on your system

- Airpack packages are suitable for hazardous areas

- Airpack packages resist extreme low or high temperatures

- Short start-up time

- Spare parts delivery

- ISO certified

- Worldwide maintenance and commissioning / start-up supervision services

Compressor packages

Airpack has several available compressors types like:

- Reciprocating compressors, oil free and oil flooded

- Screw compressors, oil free and oil flooded

- Gas compressors, reciprocating only

- Booster reciprocating compressors

- Centrifugal compressors (only for explosion proof areas, extreme ambient conditions and up to 25,000Nm³/hr)

For gas compressors and larger capacities we apply Ariel bare compressor block. Ariel is world’s largest gas compressor manufacturer.

Accessories like oil and air/gas coolers and filters, and oil and water pumps are available in dual or single configuration in all possible constructions. These include pressure vessels, separators, pulsation dampers, control panels, PLC, instruments and valves which can be applied in all materials, types and makes available in the market.

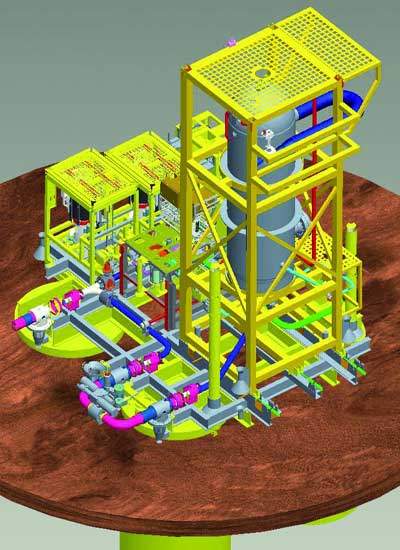

All compressor packages built on heavy-duty skids can be engineered and manufactured fully according to clients specifications. We offer optional stainless steel piping, explosion proof requirements, SIL and redundant certified PLCs and earthquake proof variants.

Air and gas dryer packages

The air and gas dryer packages consist of a complete skid-mounted dryer of several types. Each dryer will be designed according to its required dew point, operating capacity, pressure and temperature. Along with the dryer itself all types of filters in single or duplex configuration, control panels, PLC, instruments, valves etc. can be applied in all materials, types and makes. Airpack engineers and manufactures according to ASME VIII div. 1 standard and in stainless steel and explosion proof variants.

Pressure dew points up to -80°C under pressure can be obtained for heatless regenerated and heat regenerated dryers. Refrigerated dryers can achieve pressure dew points up to 3°C. A complete air or gas dryer can, along with its dedicated air or gas compressor, be packaged together on a common skid.

Airpack has several available dryer types:

- Heatless regenerated dryers

- Heat regenerated dryers

- Refrigerated dryers

- Membrane dryers

Nitrogen generator packaging

Airpack has a complete program of nitrogen generators. Nitrogen generators separate compressed air in a product stream of nitrogen and a (waste) stream of enriched air. The waste stream will be vented to the atmosphere, while the nitrogen is directed to the system. Nitrogen is most often used as a safety gas to avoid hazardous situations, such as fire or explosions, and is often applied in a gas environment. Applications can be purging, blanketing or inerting.

There are two principles available to generate nitrogen, which are:

- Hollow fibre membrane

- Pressure Swing Adsorption (PSA)

The nitrogen generator package consists of a complete skid mounted unit with membrane separator modules or PSA system, all types of filters in single or dual configuration, control panels, PLC, instruments, valves etc. and compressors and dryers providing required quality of feed air to nitrogen generator, which can be included on request.

All these components can be applied in the different materials, types and makes available in the market.