Novarc Technologies is a full-stack robotics powerhouse that prides itself on specialising in the design and manufacturing of collaborative robots (cobots) and artificial intelligence (AI)-powered machine vision solutions tailored for autonomous welding. Our Spool Welding Robot (SWR™) holds the distinction of being one of the world’s pioneers in pipe welding applications.

With a team of dedicated experts and innovators, Novarc constantly pushes the boundaries of technology. Our objective is to address and resolve the most pressing welding automation challenges, ensuring our customers experience not only improved production rates but also an enhanced bottom line.

Novarc Spool Welding Robot (SWR™): changing the landscape of the offshore industry

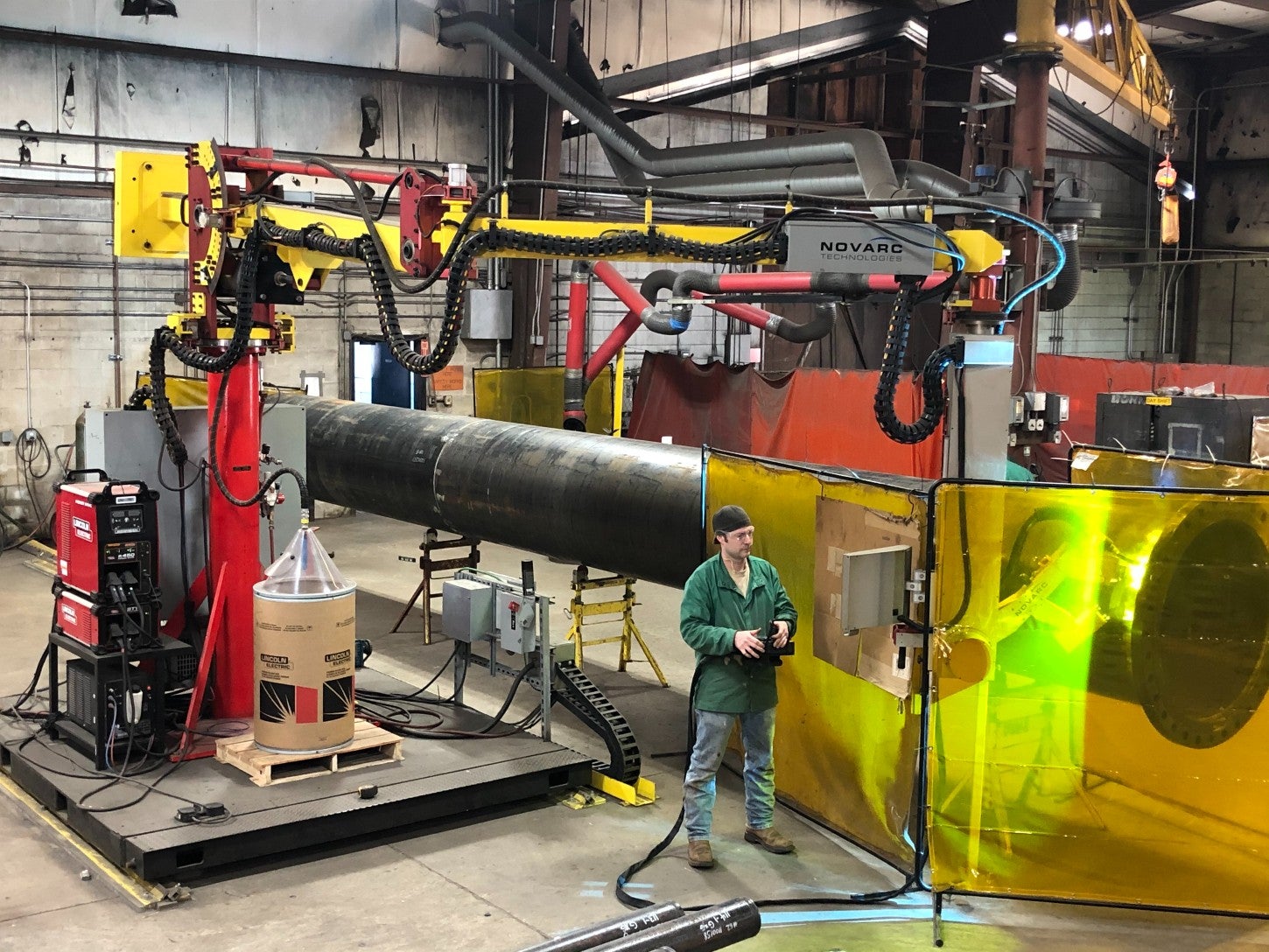

The Spool Welding Robot is a welding cobot designed specifically for pipe, small pressure vessels, and other types of roll welding.

The SWR™ is designed for carbon/low alloy (P1) and stainless steel (P8) alloys and can weld from 2in to 60in-diameter pipes and pressure vessels. With its compact 4’x4’ base, the SWR™ offers the smallest industry footprint, fitting seamlessly into most shops. Combined with its ability to integrate with up to five positioners, it ensures maximum welding productivity.

In the offshore industry, where safety is paramount, the SWR™ stands out as a prime example of using technology for worker protection. As a collaborative robot, it keeps human welders away from harmful fumes, UV light, and intense heat.

By leveraging the SWR™, our customers are not just adapting, but they’re setting new industry benchmarks:

- Improved Productivity: Our customers are achieving up to 12X increase in pipe welding productivity.

- X-ray quality welds: The SWR™ lowers the repair rates to less than 1%, compared to the industry average of 3%-5%.

- Competitive Edge: Our customers have been able to increase the margin on their existing projects, and shorten their project timeframes.

- Addressing Workforce Gaps: The SWR provides a solution to the ongoing welder shortage, supporting steady operations.

Efficiency and productivity

The Spool Welding Robot is designed for optimal efficiency. Traditional welding methods are labour-intensive and time-consuming, resulting in extended project timelines. In contrast, the SWR™ can weld non-stop from root to cap and work around the clock without breaks or fatigue. This continuous operation significantly accelerates the pipe welding productivity in the offshore industry. With the SWR™, fabrication shops are seeing between 3x-5x increase in productivity on carbon steel, and up to 12x productivity increase on stainless steel pipes.

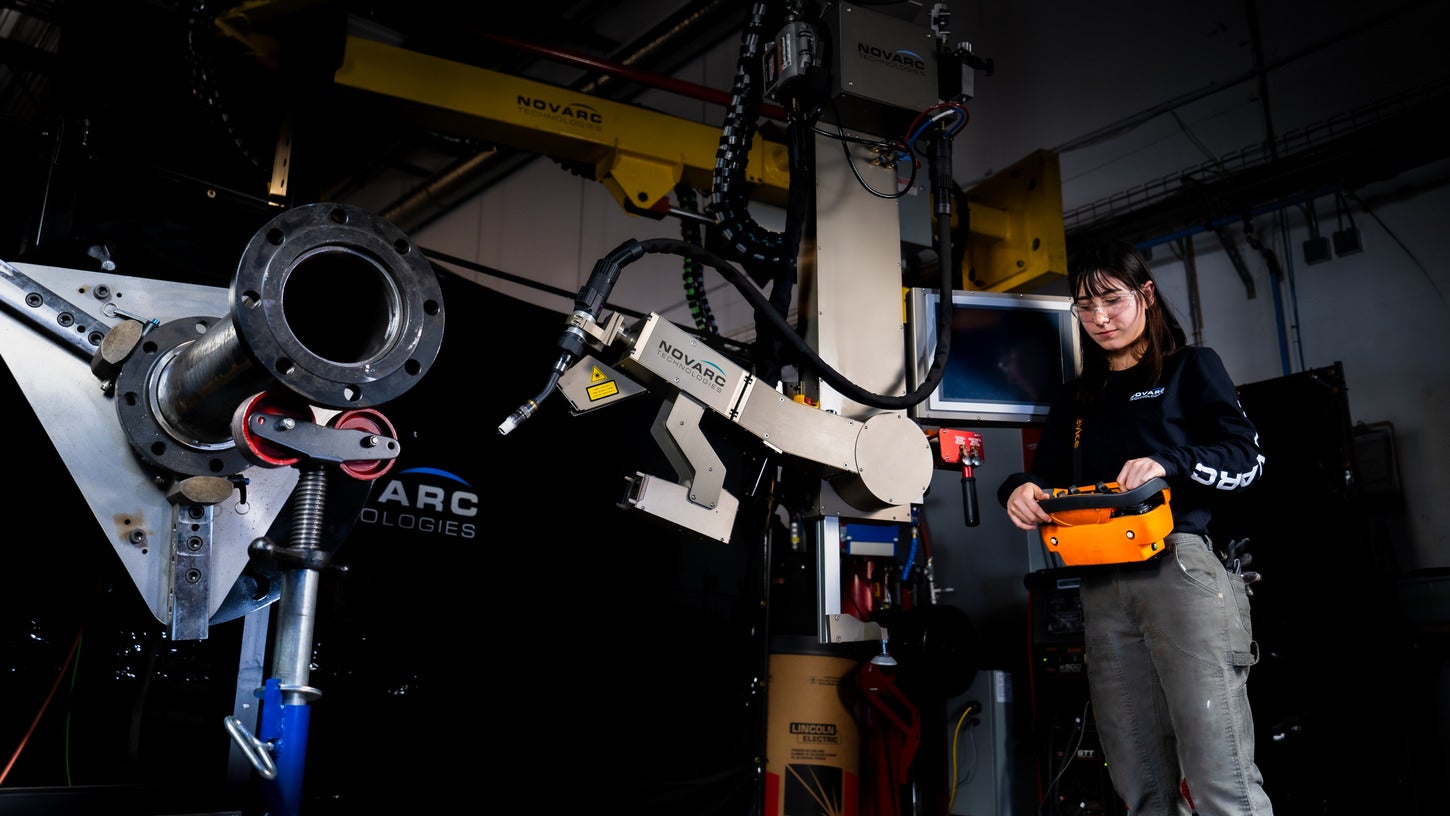

Precision and quality

Pipe welding demands a high level of precision, and even the smallest error can have significant consequences. The SWR™ is designed to tackle this challenge head-on. With its advanced vision system, it ensures welds are executed with pinpoint accuracy, minimising the possibility of human error. This level of precision is vital not only for structural integrity but also for reducing rework and costly repairs. QA and QC managers will be pleased to know that the SWR meets key quality test requirements such as the Radiography test, the Charpy Impact test, the Hardness test, the Bend test, the Tensile test, and more. The SWR welds to ASME B31.1, ASME B31.3, EN 13445 and EN 13480 standards. Shops that use the SWR consistently hit under 1%, while some shops achieve 0% repair rates.

If you’re currently producing 6,000 welds per year with a 3% repair rate, you’re likely spending around $180,000/year in repairs. By reducing the repair rate to less than 1%, you can put the repair costs back onto your bottom line.

Cost savings

SWR™ is an epitome of long-term investment returns. Its deployment results in tangible savings—be it reduced labour costs, minimized rework, or expedited project completion. All these factors combine to present a compelling financial case for fabrication shops to make the switch.

To illustrate the remarkable efficiency of the Spool Welding Robot, let’s delve into a real-world case study from Novarc Technologies.

Case study: enhancing fabrication for offshore platforms

One of North America’s largest and most respected Engineering Procurement and Construction companies purchased two of Novarc’s Spool Welding Robots to work collaboratively with welders at their fabrication facility constructing large, complex offshore platforms.

The results of this collaboration were nothing short of remarkable:

- Achieved an eight-month ROI on the SWR™

- Ability to produce more units on the same shop footprint. The facility on average welds about 500 spools a week, in a 100’ x 100’ building. A typical pipe shop is about three times that size and has the same production rates.

Offshore platform construction and maintenance is challenging, high-risk work. In addition to safety concerns, the welding industry is faced with a shortage of skilled welders as many are retiring, and not enough young labourers are entering the profession. And then there’s the competitive nature of fabrication shops serving the manufacturing industry.

One of the executives said: “The cost of labour is rising and labour is getting scarcer, so more companies are moving towards automation because it’s the only way to survive. If they don’t invest in technology automation, then they probably won’t be around for another ten years.

“There’s nothing that I’ve seen in the market in the last two years to even come close. What sets Novarc apart is the ease of use of the tool and the fact that it is user-friendly. The SWR has the end-user in mind. Once you buy the robot, you have the tech support and everything to assist you so you’re not standing alone. And on top of that, it’s hard to replace the machine once you have it, because there’s nothing really that can weld much faster or better.”