MACAW Engineering is a leading independent engineering consultancy working closely with global operators of oil and gas production facilities, pipelines and utility systems to reduce risk, maintain integrity and extend the service life of client assets. Our principal engineering consultants are able to draw on more than 25 years of industry experience in materials, corrosion, welding and asset integrity.

MACAW Engineering applies this knowledge to develop and provide cost-effective solutions to our clients across the energy sector. These solutions are often employed in maintaining the integrity of ageing assets and extending their service life.

Where new developments are proposed by operators (frequently those involving existing infrastructure), we identify and analyse technical issues that may impact the future integrity of a project, in order to specify an optimised plan.

MACAW has extensive knowledge and experience of:

- Integrity management

- Corrosion mechanisms

- Materials (carbon steels, CRA materials and polymers)

- Coating systems

- Inspection methods

- Welding consultancy

- Failure Investigation

Our client list reflects the fact that the energy industry operates in a global market. We have provided services to major oil and gas operators in more than 40 countries worldwide, ensuring that we are responsive and our services are customised to client needs.

MACAW services include:

- Pipeline and plant integrity management

- Materials and welding consultancy

- Corrosion control and management strategies

- In-line inspection (ILI) data review and diagnosis

- Risk assessments

- Planning and prioritising inspection, maintenance and repair (IMR)

- Fitness-for-service (FFS / FFP) assessment

- Site surveys and audits

- Failure investigations

- Experimental engineering

- Safety cases, regulatory issues and standards

- Representation on national and international standards bodies

Asset integrity management

MACAW provides asset integrity management solutions to a global client base. Whether your asset is an onshore terminal, offshore rig or processing plant, MACAW has the technical knowledge and experience to support all aspects of asset integrity management, with particular focus on ageing assets and maintaining operational integrity.

Asset integrity management services offered include:

- Risk-based inspection (RBI) schemes

- CP design, installation and performance audits

- Materials review

- Integrity issues for new developments

- Life extension studies for ageing assets (HSE KP4)

- Safety cases, regulatory issues and standards work

- Development and implementation of RBI and IMR planning systems and application software

- Company placements contributing to AIMS and PIMS

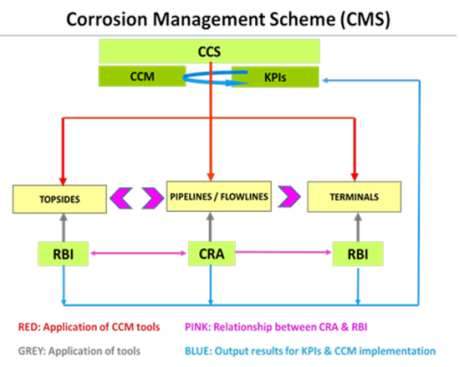

Corrosion management

MACAW’s understanding of the complex challenges that are associated with corrosion issues on ageing assets, particularly in offshore environments, has provided a cost-effective platform for many operators to form corrosion management strategies. We can offer solutions that maximise production uptime while maintaining the highest possible safety standards.

Corrosion management services include:

- Corrosion management systems audit and gap analysis

- Development of corporate corrosion management policies

- Corrosion control strategies (CCS)

- RBI of for assets (and processes) that affect pipeline integrity

- Corrosion risk assessment (CRA) for assets (plant, vessels, pipework and pipelines)

- Pipeline risk assessment (PRA) for subsea pipelines and risers

- Corrosion mechanism analysis, modelling, growth and failure assessment

- Review of cathodic protection (CP) systems

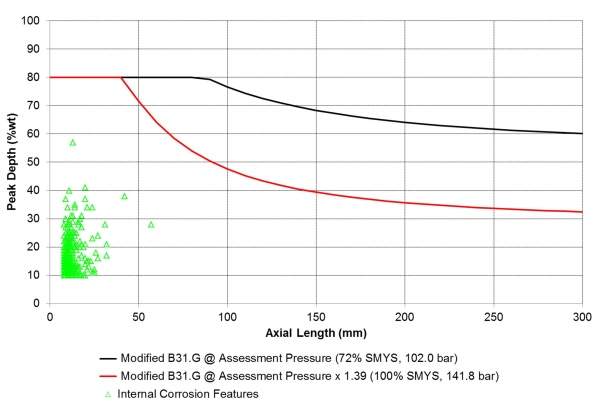

Pipeline integrity

Our Integrity Group has unrivalled experience in interpreting ILI data, providing fitness-for-purpose assessments and corrosion growth analyses, leading to optimised ongoing integrity management through scheduled repairs and inspection intervals.

Integrity services include:

- Risk assessment

- FFS / FFP assessments

- Corrosion growth analysis (including raw signal data comparison)

- Crack and lamination assessment (fracture and fatigue)

- Geometry assessment (dents and ovalities)

- Remaining life assessment

- Development of integrity management plans (IMP)

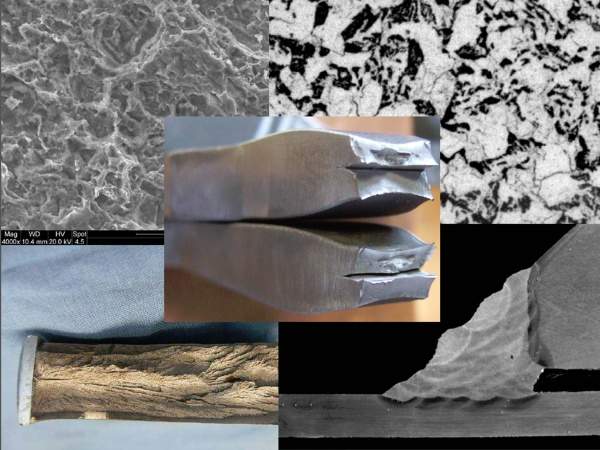

Welding and materials

MACAW’s team of welding and material engineers provide support to a range of global pipeline operators and fabricators. With unequalled experience in material manufacture and fabrication standards, we can support all types of projects. With a focus on quality and repeatability, our engineers can provide advice and assistance from the pre-FEED stage right through to commissioning and acceptance.

Materials and welding support services include:

- Welding procedures

- Pipe and fittings material specifications

- Supplier capability assessment and audit

- Weldability and in-service welding

- Pipeline construction audits

- Technical concessions / deviations

- Codes, standards and specifications

- Trouble-shooting and failure investigations

- Training

Engineering services

MACAW offers bespoke corrosion, pressure and experimental testing, as well as specifying, managing and witnessing standard mechanical tests and offering result interpretation from a range of UKAS-accredited laboratories.

Engineering services include:

- Material identification (including live pipelines and plant equipment)

- Failure investigation

- Soil resistivity and corrosion assessment

- Cathodic protection monitoring (land-based or near shore)

- Paint and coating inspection

- Full-scale testing of low-pressure steel / polyethylene pipelines / joints / assemblies

- Hydrostatic and pneumatic pressure testing up to 1,200bar (in-house and on-site)

- Micro and macro photography capabilities

- Range of research and development (R&D) services

- Condition assessment

- Material sampling

- Corrosion testing of coatings / materials (high temperature and pressure)

- Metallurgical examination

- Material and environmental studies

- Bespoke test rig design and operation for a range of experimental applications

Engineering services support includes:

- Material sampling

- Failure investigation

- CP consultancy

- Site inspections / audits

- Laboratory-based testing

- Bespoke test rig design and operation

- Failure analysis and metallurgical examination