IODS are international specialists in weld cladding, pipe cladding, clad pipe fitting and fabrication, combining cutting-edge technology with 25 years of world-renowned expertise. IODS offer full supply of weld clad components, pipe and fittings to the oil and gas and offshore industry.

IODS OIL TOOL EQUIPMENT CLADDING

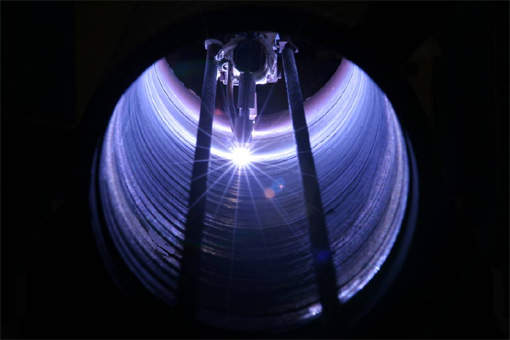

IODS moved into a custom-built facility in 1994 complete with fully automatic hot-wire tig-weld overlay stations and offers component cladding by means of fusion welding, using alloys such as Inconel 625, 725, 825, C22, C276 and a full range of 3 series and 4 series stainless steels.

Due to their vast experience and knowledge IODS are able to offer a cost effective solution for all industry problems involving corrosion, wear, erosion and cavitation.

PIPE CLADDING – CLAD PIPE AND INDUCTION BENDS

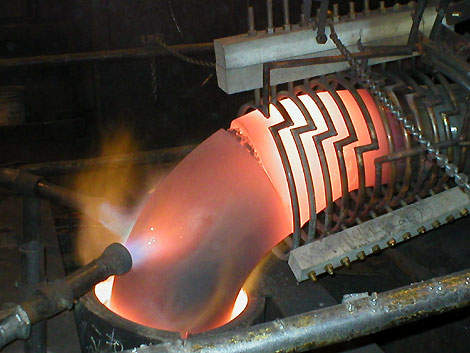

IODS PIPE CLAD is the division of IODS primarily concerned with the manufacture of clad pipe and induction bends. IODS PIPE CLAD operates 15 technologically advanced pipe-cladding machines capable of welding of double-random lengths (up to 12m):

- 90mm to 600mm nominal bore depending on length

- 6mm to 75mm in thickness

- 1D, 3D, 5D and 7D radius bends

- Surfacing materials range from 3 and 4 series stainless steels to high nickel alloys

CLAD PIPE FITTINGS – EQUAL AND REDUCING TEES, LATERAL TEES, CONCENTRIC REDUCERS AND ECCENTRIC REDUCER

IODS manufacture a wide range of clad pipe fittings including equal and reducing tees, lateral tees, concentric reducers and eccentric reducers and elbows (both long and short radius), weld caps and extruded header manifolds. We also supply a wide range of weld neck and blind flanges:

- Material grade fittings: ASTM A234 Grade WP 5, 9, 11, 22, 91

- Material grade flanges: ASTM A182, Grade F5, F9, F11, F22

FABRICATION

Fabrication using computerised, fully programmable orbital welding machines on clad materials:

- Stainless steels 304L and 316L

- Inconel 625 and 825

- 22% and 25% Duplex

- Highly trained experienced welding operators ensuring high quality, both radiographically and surface finish

PROJECT MANAGEMENT

IODS dedicates a project manager to individual projects in order to enhance the flow of communication between IODS and their customers and create a trusting relationship between manufacturer and client. The remit extends from contract award to after sales and includes decision-making power regarding allocation of additional resources that may be required during any phase of the project.

COMPANY HISTORY

IODS was formed in 1983 as a member of the Glenalmond Group of companies. IODS have been BSI registered since 1988 and are currently certified BS ISO:9001 2000.

Sister company VALVE COMPONENTS LTD are a valve and actuator manufacturer offering turnkey engineering solutions to original equipment manufacturers within the oil, gas and petrochemical industries.