For over 23 years, Advanced Piping Products (APP) has set the benchmark for developing highly engineered and dependable composite pipe support technology that provides excellent protection against corrosion, therefore prolonging the life of valuable piping systems. The world’s leading energy and chemical companies have trusted APP for continuing to innovate the next generation in pipe supports.

Recent piping projects

We at APP are proud to say we have a proven track record with zero failures. Our more notable projects include:

- Exxon’s Kizomba A & B

- Exxon Mobil Baytown

- Exxon Mobil Baton Rouge

- Petrobras’s Caratinga

- Petrobras’s P-51, P-52, P-56, P-57, P-58, & P-62

- Chevron’s Jack & St Malo

- Chevron’s Bigfoot

- Chevron Oronite

- BP’s Thunder Horse

- Valero Refinery in Texas City

- Conoco Phillips’s Magnolia (TLP)

We have also worked with a number of EPC partners, such as:

- Jacobs

- Mustang

- KBR

- Foster Wheeler

- Fluor

- McDermott

- Technip

- CB&I

- AMEC

- Modec

- Sofec

- Burns & McDonald

- Worley Parsons

- Alliance

APP is a unique manufacturer of composite pipe supports that provides dependable solutions and stellar customer service by strategically planning, executing, training and inspecting projects as necessary. Our value-added services bring an additional dimension of support for end users, engineers, contractors and supply houses.

As a corporate member of NACE International, Cryogenic Society of America and Society of Piping Engineers & Designers, APP is at the forefront of industry changing composite pipe supports.

Cost-effective composite pipe supports

As an industry leader in composite pipe supports, we offer products that save the oil and gas industry millions of dollars in maintenance throughout the total cost of ownership.

Pipe support solutions for extreme temperatures

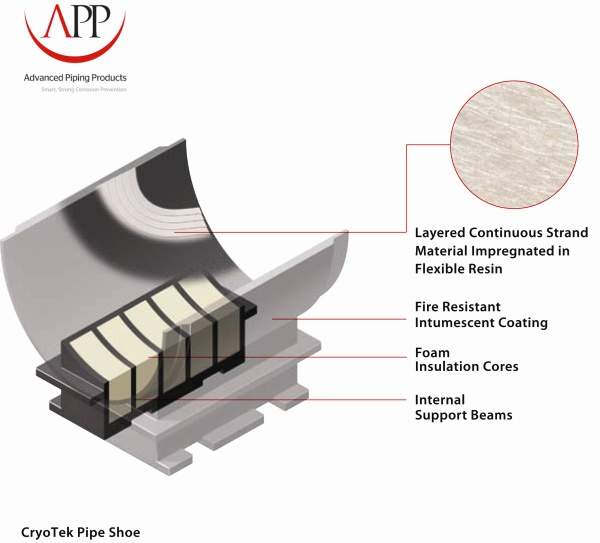

APP CryoTek pipe shoe is an excellent non-metallic pipe support solution for extreme temperature conditions, such as in pipe systems with extreme cold pipe temperatures, and LNG terminals, carriers and ethylene plants.

Newly developed composite technology provides 8% flexibility while maintaining a compressibility factor of 27,500 PSI, and it is operational on temperature ranges of -320°F to +400°F.

Resistant to degradation from electrochemical corrosion and/or UV exposure, its intumescent coating allows a fire rating of two hours at 2,000°F without compromising structural integrity, and its monolithic design eliminates secondary adhesion problems for maximum strength.

The APP CryoTek shoe has a sealing structural member that safeguards the moisture seal from being compromised, and a fibre-reinforced internal partition that supports the weight of the pipe and contents while protecting the low-density polyurethane insulation cores.

Advantages of APP CryoTek include:

- Maintainance of operating temperature and elimination of condensation at pipe supports

- Installed cost is usually less than half the cost of pre-insulated steel cryogenic supports

- Weight of CryoTek shoe is significantly less than the alternatives, reducing freight and handling costs

- Eliminate corrosion due to metal-to-metal contact

- No welding or lifting machinery needed for installation

- Customisable to any height, length or width

Elevated pipe systems

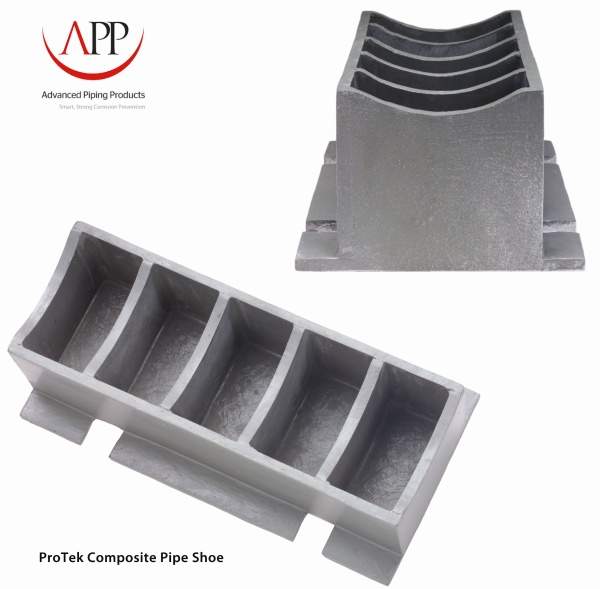

APP ProTek pipe shoe is a UV-resistant non-metallic solution for elevated pipe systems at support points, with 165,000lbs of compressive strength, with a temperature range of -320°F to 400°F and resistance to chemical attack. Designed as support for insulated piping systems and other offshore applications, as well as in plants and refineries.

Advantages of APP ProTek include:

- Prevents corrosion at support points

- Maintain operating temperature by not transferring heat

- Weight of ProTek shoe is less than a quarter of metallic equivalent

- Reducing freight and handling costs.

- No welding or lifting machinery needed for installation

- Customisable to any height, length or width required

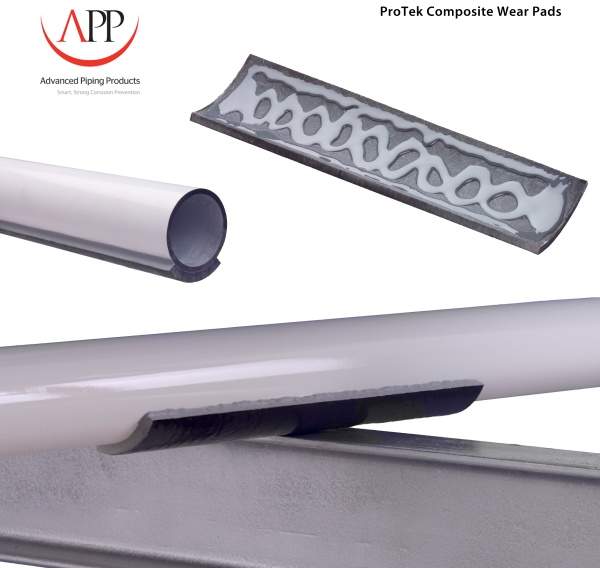

Un-insulated pipe systems for upstream, midstream and downstream applications

APP ProTek wear pads are a non-metallic solution for un-insulated pipe systems at support points, with 54,000lbs of compressive strength, 8% flexibility and a pre-roughened inner diameter profile.

Advantages of APP ProTek wear pads include:

- Prevention of corrosion at support points

- No metal to metal contact

- Easy installation

- Provision of a non-metallic load bearing surface between the pipe and pipe support

- Reduces cost of maintenance

Hold down clamps for vibration dampening

APP VibraTek hold down clamp is a great solution to dampen vibration, with a VibraTek lining to absorb the vibration and prolong the system. With specialised Teflon mechanically bonded to the lining for a low-coefficient of friction, the APP VibraTek clamp prevents corrosion at hold down points and offers easy installation and reduced cost of maintenance.

Applications include vibrating lines such as a centrifugal pump, as well as other upstream, midstream or downstream applications.

Metallic pipe support options

Although composite pipe supports have a wide range of benefits and applications, we at APP understand that sometimes the industry requires a broad aggregate of metallic pipe supports to meet their project’s needs. That is why we at APP also offer an expansive selection of metallic pipe supports and accessories.