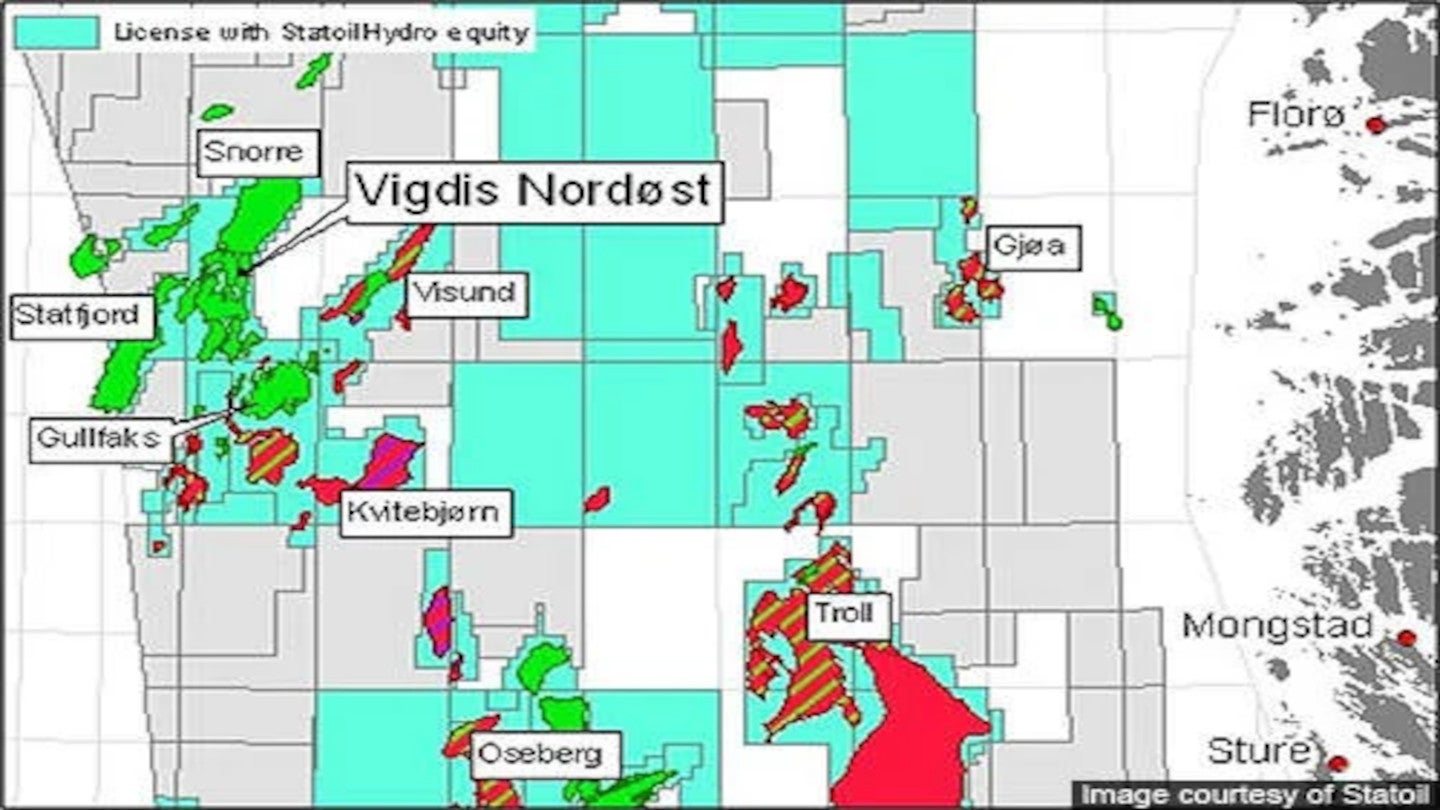

Pipeline Research Limited was established in 1999 to provide design and consultancy advice on difficult-to-pig pipelines and pigging problems. Issues such as dual and multi-diameter pigging, compressible flow and two-phase gas / liquid pigging, pipeline cleaning and dewaxing, cleaning frequency, bypass pigging, pig development and testing, and pipeline pre-commissioning have formed part of the service over the years. Clients include BP, Statoil, Total and Woodside.

In addition, Pipeline Research is the technical advisor to the Pigging Products and Services Association (PPSA) and has provided expert witnessing and support for pigging-related problems.

Dual and multi-diameter pigging

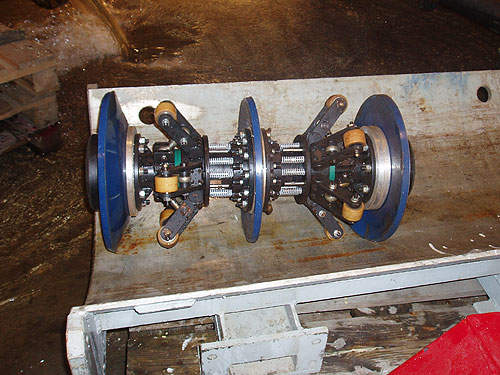

Design and development of dual and multi-diameter pigs is a major part of our business. These pigs have been developed for batching, sealing, cleaning and towing inspection pigs through difficult lines with major diameter changes.

Recently, dual-diameter, bi-directional sealing pigs have become important for pipeline pre-commissioning. We have tested and developed such pigs for Statoil, Norway, in conjunction with FTL Seals Technology and Pipeline Pigging Technology.

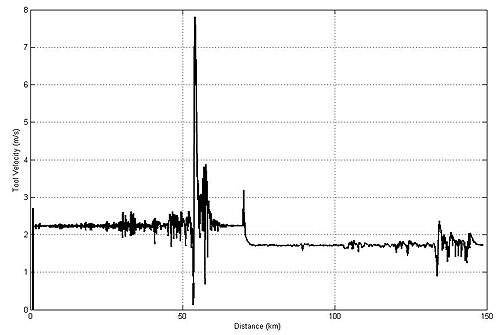

Compressible pigging model

We have developed an in-house tool, known as PIGLAB, for determining the pig velocity profile when pigging gas pipelines. This has been applied to MFL tool deployment in low-pressure gas lines, UT tool batch pigging and the removal of plug trains from gas pipelines. The output is pig velocity against distance.

Work is proceeding on a two-phase gas liquid model to determine the velocity profile of a pig and liquid hold-up downstream of the pig in a two-phase gas / liquid pipeline.

High-bypass pig analysis

The removal of liquid from a gas pipeline or water from an oil pipeline is an area that can often cause issues with receipt of large volumes of liquid or water. Pipeline Research Limited provides analysis of the use of high-bypass pigs to limit the flow of liquid in the process facility.

Pipeline cleaning and dewaxing

The removal of wax and debris from pipelines is important for efficient product throughput and for pipeline inspection. Pipeline Research Limited aid in difficult-to-pig lines, including low velocity and lines that have not been pigged regularly.

Pipeline Research Limited has developed a method of establishing dewaxing pigging frequency and is involved in an R&D project with Statoil on this issue. This leads to a pigging strategy. Avoiding wax plugs in small bore lines is vital and bypass pigging is an important consideration.

Pig testing and development

Pipeline Research Limited is often tasked with providing assurance that a pig will negotiate a pipeline. If this cannot be established on paper and drawing, then a test is required. We have been involved in testing at K-LAB in Norway and other establishments. We have helped to organise the test work and reviewed the testing to assess piggability.

We provide design advice and specification of the pigs for manufacture. Interpretation of damage to pigs and why such damage occurs is considered. We advise on recovery of stalled and stuck pigs using recovery pigs or other methods.

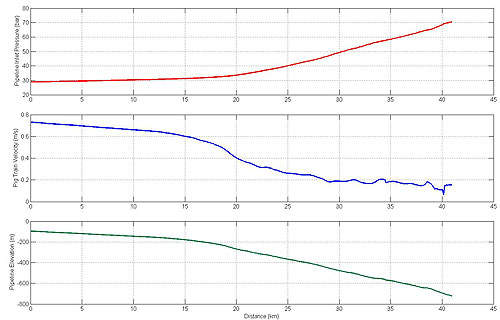

Pipeline pre-commissioning

Pipeline Research Limited has a model to provide details of batching requirements, pressure requirements and pig train velocity during pipeline pre-commissioning – flooding for hydro-test and subsequent dewatering. Other calculations such as venting times, vessel deployment time and pressurising time can also be accommodated.