Optical Metrology Services (OMS) is a leading measurement, inspection and remediation company offering services and technology to the energy sector. Our robotic crawlers, tools and services have been used on most major energy extraction projects worldwide.

Clients value our unrivalled experience of providing measurement, inspection, and remediation services within the energy industry, which includes oil and gas projects and renewable installations. We work closely with clients to forge partnerships lasting many years.

Weld inspection and remediation

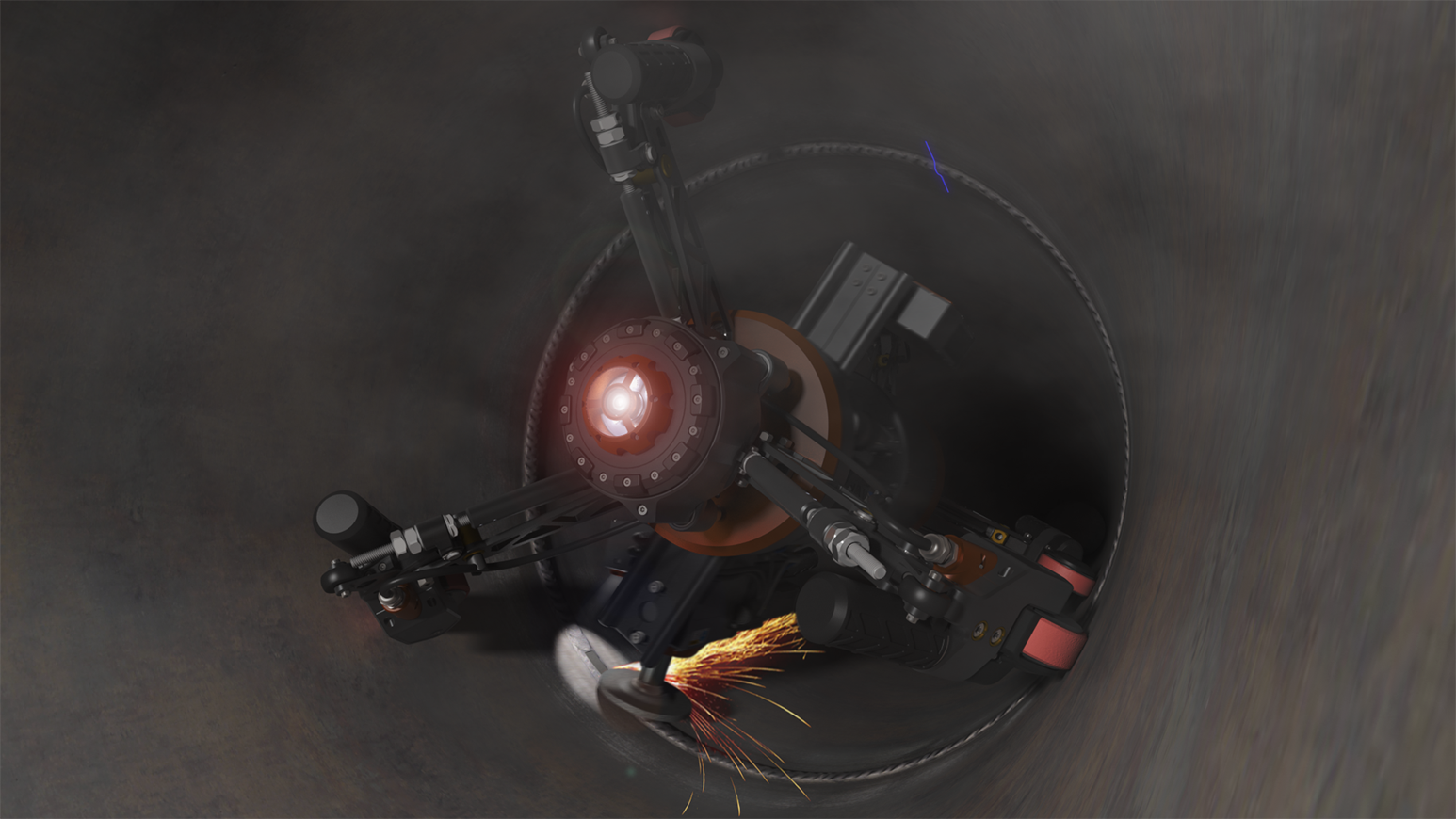

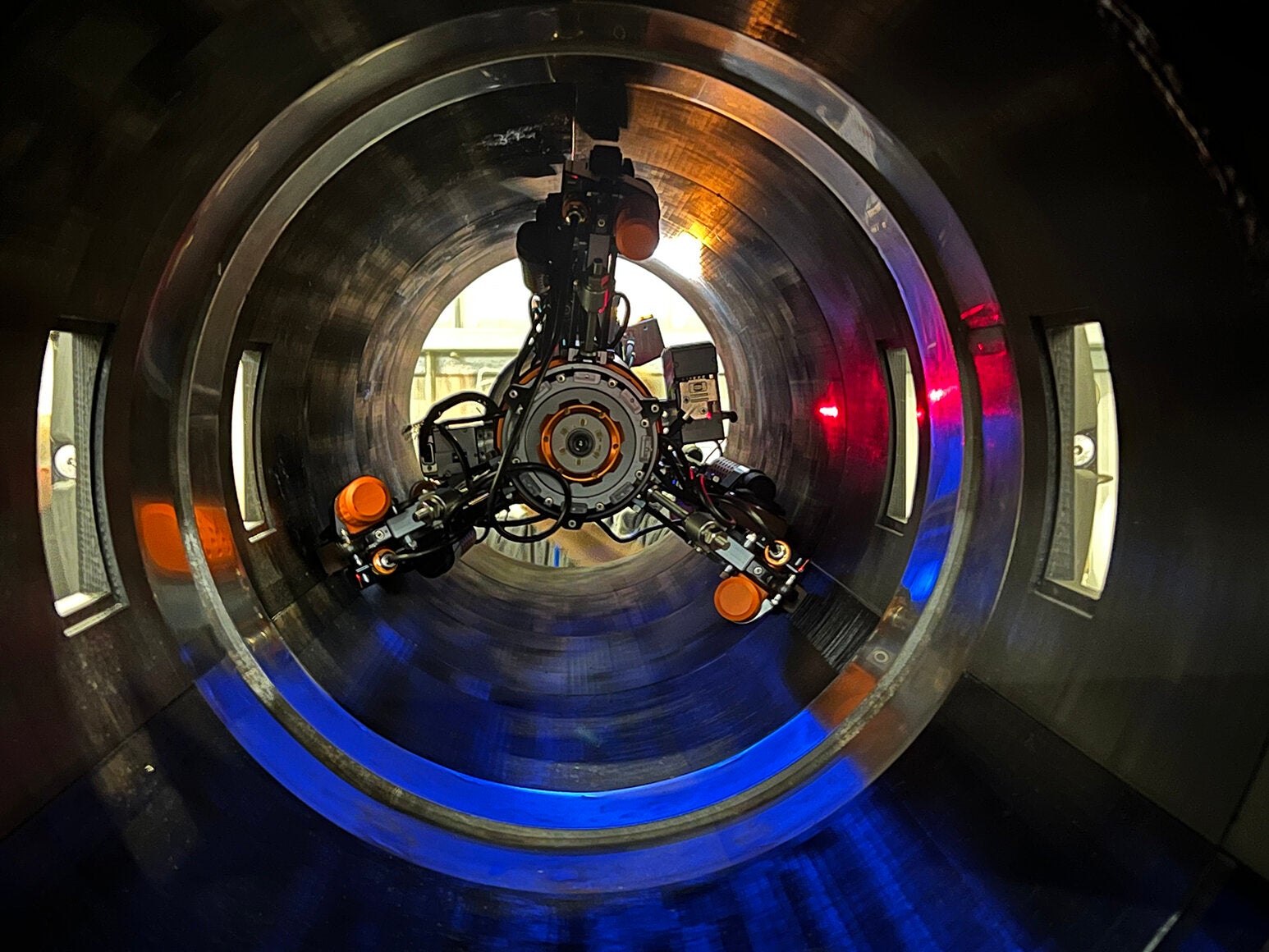

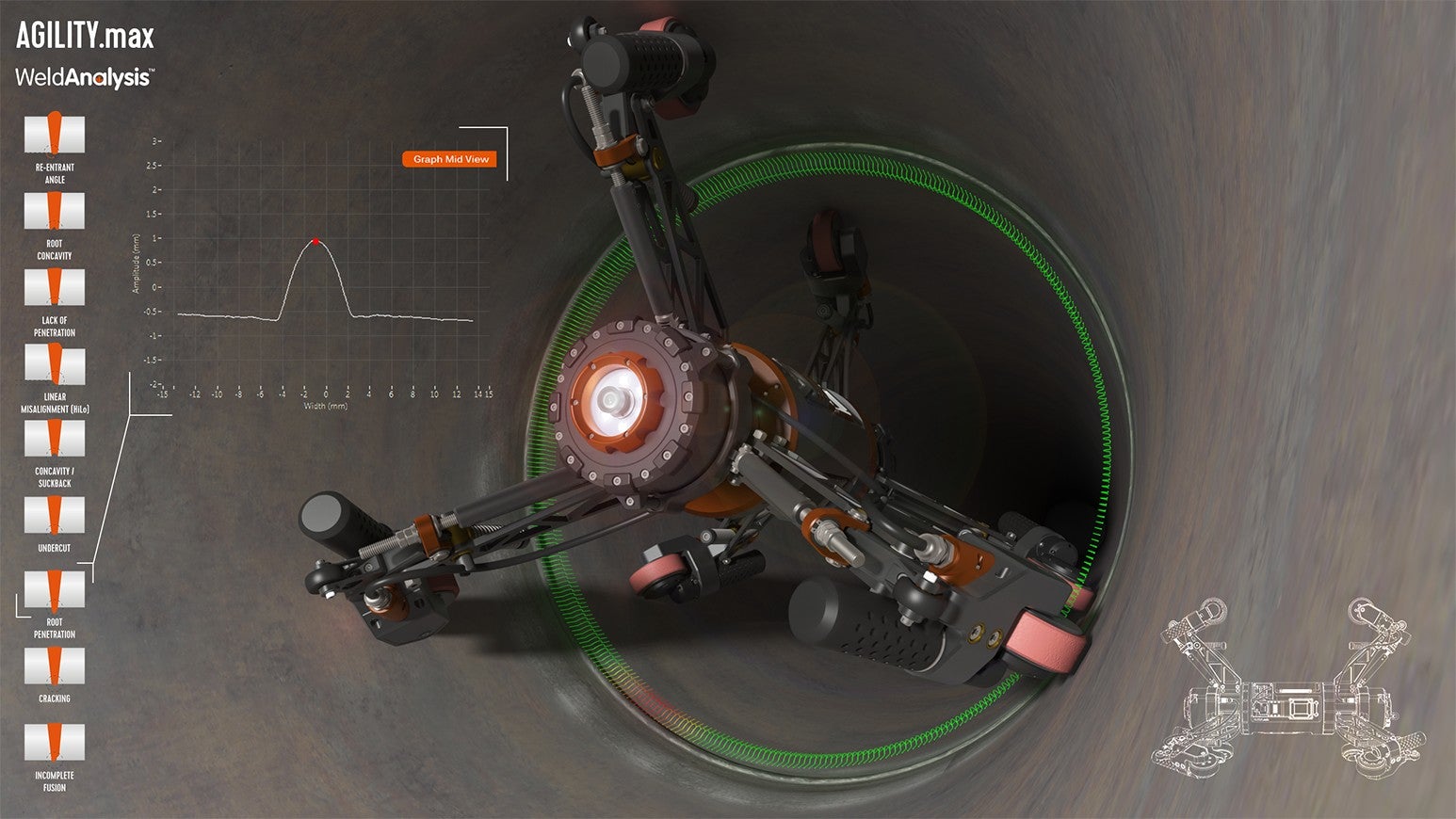

OMS provides an award-winning weld inspection service that uses a combined camera and laser system to locate and quantify defects such as weld problems or corrosion within critical pipeline sections. Our system, the AUGA.node, is deployed either through our AGILITY robotic crawlers, which are designed and built in-house, or via other methods including linear actuators and push rods. Services include cleaning and surface preparation, weld scanning, defect identification and remediation, pre-coating inspection and data analysis.

The OMS AUGA.node weld inspection system allows clients to make rapid, accurate, in-field decisions using ultra-HD cameras and laser sensors to record comprehensive visual and dimensional information on a weld. Data captured within a 25-25 second scan provides a 3D map of the weld, including its full profile, and is compatible with grinding or other remedial action.

OMS has recently launched SmartGrind, a modular addition to the AUGA.node weld inspection service. SmartGrind identifies and quantifies weld defects, such as excess penetration and spatter, and then carries out targeted repairs without loss of wall thickness before re-scanning to confirm weld quality.

Laser measurement and data

We offer market-leading laser pipe-end measurement and fit-up with a variety of tools for the measurement and detection of deviations in pipe shape. Comprehensive measurement information is available through up-to-date data reports, which also provide project specification options.

When pipes are joined together to build pipelines, any incongruity between the two ends creates welding difficulties and stress concentration areas that can later result in fatigue and even failure later down the line. Our measurement technology measures pipe ends in less than 12 seconds with a rapid laser scan that provides a full range of data on ID, OD, WT, and out-of-roundness. SmartFit software can then be used to sort, group and sequence pipes, with a ‘golden’ pipe selected for critical pipeline sections.

Laser bevel measurement

The OMS Bevel 360 tool eliminates doubt about bevel compliance and provides unrivalled insight into critical pipe bevel geometry. Ideal for pipe sizes from 6in to 32in, the Bevel 360 provides total 360° coverage of the bevel. Clients can maintain production control of bevel quality while streamlining welding processes and increasing installation efficiency.

OMS pipe measurement and fit-up services help our clients achieve optimum fit-up, even in complex critical sections, which leads to stronger, safer and longer-lasting pipelines that can be installed more efficiently.

Robotics

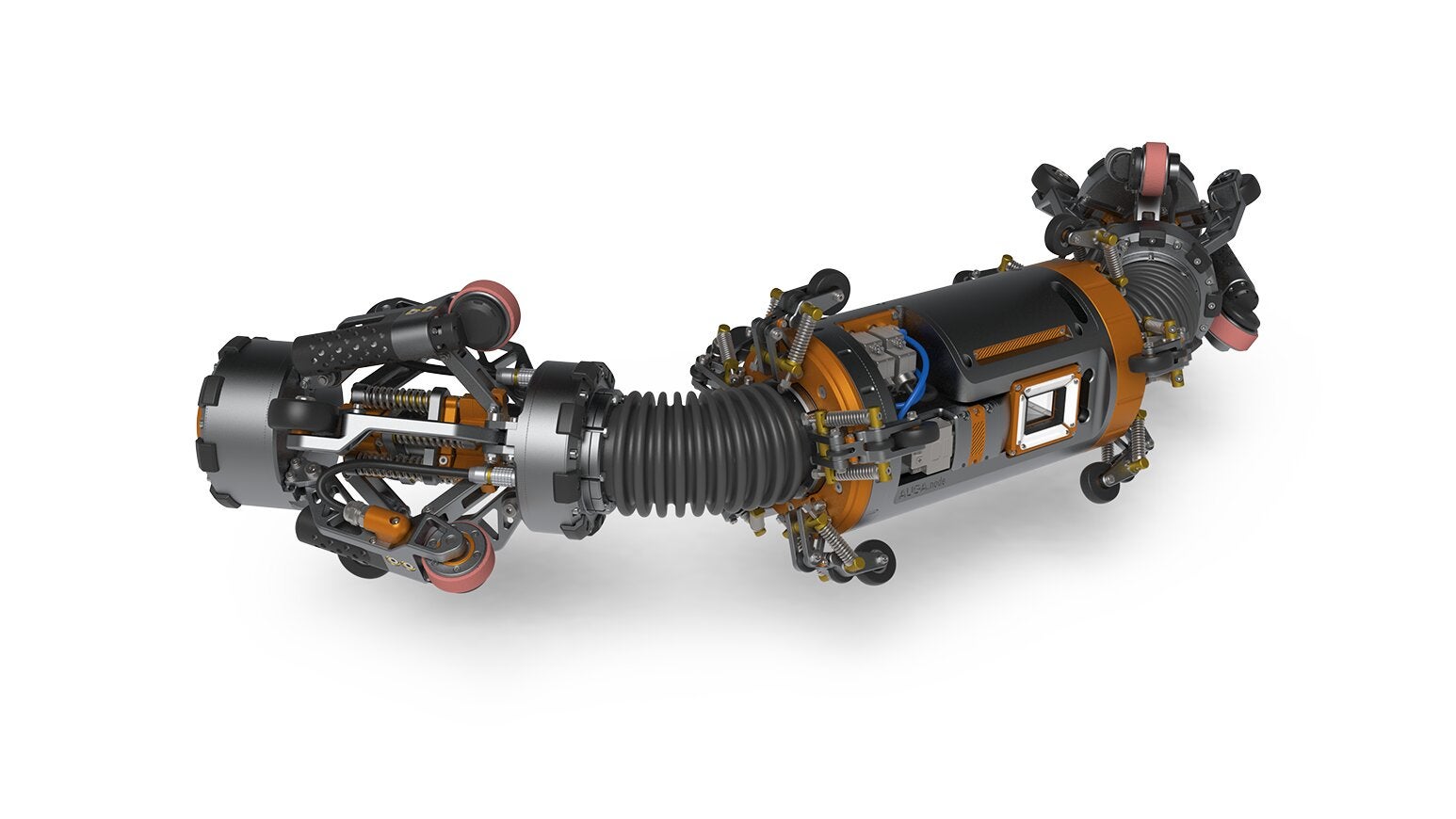

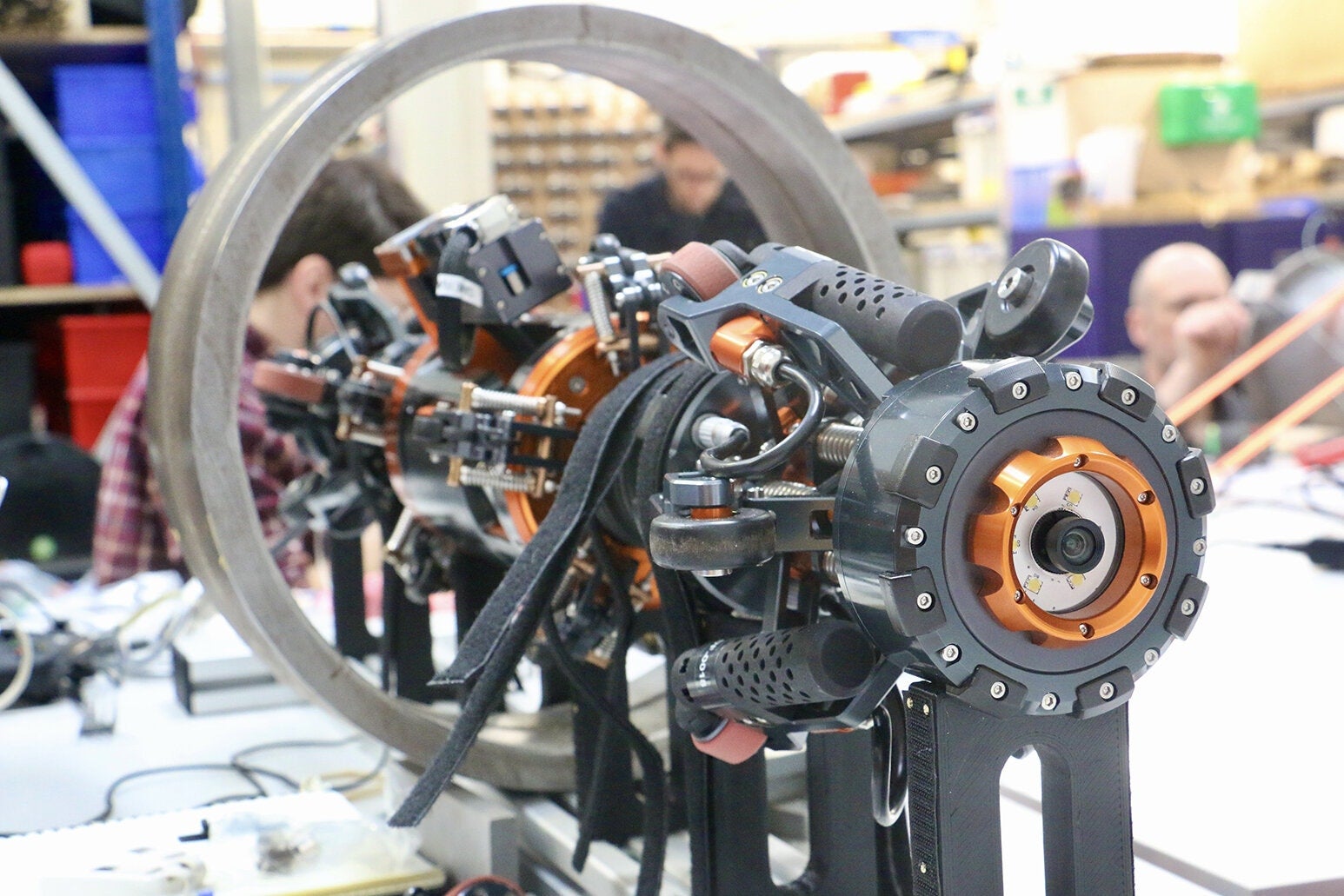

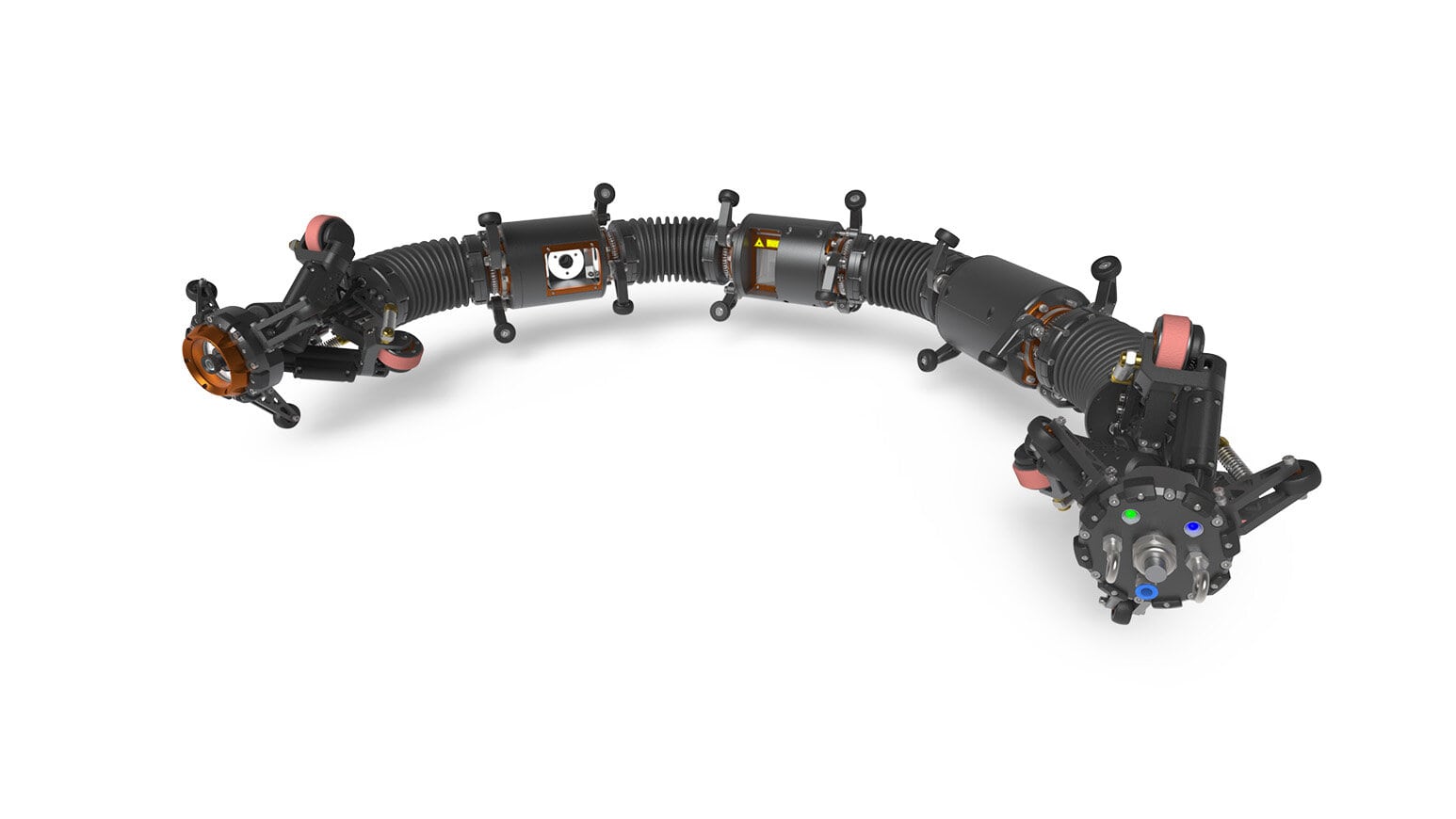

OMS designs and builds state-of-the-art robotic crawlers capable of navigating complex pipelines with multiple elbows, bends, and vertical sections. They are lightweight, portable, and easy-to-use systems that can travel more than 1km from point-of-entry. Equipped with the very latest in ultra-HD camera and laser technology, the AGILITY crawlers can access critical weld sections formerly considered unreachable.

Software development

Our software team creates and continuously enhances the flexible and customisable programs that support our technology. They frequently work on complex projects that require integration with third-party systems. OMS software is designed with user-friendly interfaces and go/no-go indicators, which are ideal for use in challenging energy environments.

Digitalisation and data tracking

OMS technology captures all digital information in one easy place for clients to access from anywhere in the world. Data is traceable and can be used to improve efficiency, safety and asset lifetime. All OMS services provide real-time data capabilities, which allow clients to gain every possible business advantage. These include cost reduction, efficiency improvement and streamlined compliance processes, all of which are vital in the heavily regulated energy sector.

Logistics

OMS clients can rely on us to respond rapidly and effectively to their requirements, even if those are complex and the situation is highly pressured. Our agile approach allows us to mobilise teams and equipment quickly, even to some of the most difficult locations. We provide a range of remote working options to help reduce costs and manage situations, such as the coronavirus pandemic and have a wealth of experience managing challenging projects that require innovative logistics solutions.

Innovation at OMS

Innovation is at the centre of OMS ethics. With over 20 years of solving energy challenges, our agile research and development (R&D) team is in a perfect position to lead new solutions inside and outside the sector. Since 2007, we have won three Queen’s Awards for Innovation, most recently for our ground-breaking AUGA.node weld inspection system.