Intrepid Global houses a specialised subsea team with over 75 years of practical experience in supporting the oil and gas industry from the well perforations to the water’s edge.

Intrepid plans, manages and executes marine operations in the worldwide offshore oil and gas industry in an innovative and cost-effective manner. We provide consulting services, marine expertise and marine supervision at the highest level of safety and quality in the industry, supported by our internal engineering and design staff.

Marine operation project management and consulting

Intrepid offers project management and engineering services for a range of marine operations.

Mooring and FPSO operation services

Intrepid provides mooring installations, FPSO hook-ups and mooring maintenance services to the offshore oil and gas industry.

In-field operations

We deliver a range of in-field operation services such as in-field jumpers and flowlines.

CALM buoy installation and maintenance

We offer CALM buoy installation and maintenance to the offshore industry, including swivel maintenance, hose replacement and mooring system maintenance.

Marine towing operations

Our range of towing operations includes define tow rigging, supply tow rigging, tow rigging installation and tug hook-ups.

Subsea operations

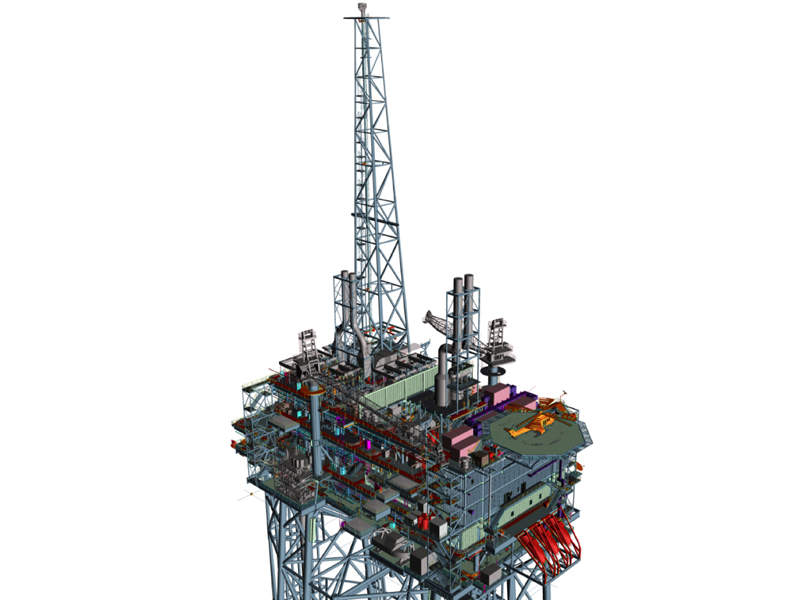

Intrepid provides a wide range of subsea operations services, including the following:

- Manifold, template and jumper installation

- Flying leads

- In-field flowlines and risers

- Remote pull-in operations

- General ROV operations

Offshore field architecture configuration and layout

We assist clients with offshore field architecture configuration and layout to promote constructability.

Preset mooring and floating production systems

Intrepid designs and pre-installs mooring systems well in advance of the arrival of hook-ups of floating production systems. We also plan, manage and execute the towing and hook-up of floating production systems.

Subsea umbilicals, risers and flowlines

We provide design, operation, repairs and maintenance services for subsea umbilicals, risers and flowlines (SURF).

Highly experienced personnel

Intrepid delivers flexible solutions, meeting our clients’ needs at the highest standard with no compromise on the Health Safety Security Environment (HSSE). We have a mix of highly professional personnel, including experienced engineers, mariners, hydraulic system specialists, HSSE mechanics, welders and riggers, who are key to our success.

Anchor handling tug supply vessel

The Lewek Falcon is designed to meet the harsh North Sea’s condition to undertake supply duties between land bases and drilling sites, towing assistance during tanker loading, towing of threatening objects and deepwater anchor handling. Vessel service capabilities include: field inspection, maintenance and repair (IMR) duties.

- Length: 93.4m

- Breadth: 22.0m

- Total: 23,467 BHP

- Deck area: 815.0m²

- Bollard pull: approx. 300t

- Dynamic position DP (AA)

- 100 men accommodation

- Rig chain locker: four tanks, 780.0m³

- 2 x 150hp 3,000m workclass ROV

- Multiple deepwater A/R winches

- 150t subsea crane

- 350t A-frame

Construction and flexible lay vessel

The Lewek Crusader is a state-of-the-art construction, installation and commissioning DP-3 vessel fitted with advanced systems such as a vertical lay system (VLS) for flexibles and control umbilicals, a 600t main lift crane and a 200t knuckle-boom AHC. These advanced platforms provide a broad set of capabilities in water depths up to 3,500m.

- Length: 134m

- Breadth: 32m

- Cargo deck area: 2,100m²

- Two heavy work class ROV rated at 4,000 MSW

- Class III DP (AAA) system with LRS

- 400t Huisman pedestal crane

- 200t active heave compensated knuckle boom crane 3,000m

- 7.1 m x 7.1 m moonpool for deployment of equipment or rigid well workover

- 600t SWL A-frame / deployment system to 3,000m inclusive of traction winch system (optional)

- Huisman flexible vertical lay system (optional)