Urbica is a French service company that specialises in three-dimensional (3D) laser surveys. For a number of years, Urbica has undertaken the capture of 3D measurements in the industrial sector. 3D scanning has already revolutionised the methods applied by design offices, maintenance companies and major industrial operators, specifically in the oil, gas and chemicals sectors.

Urbica’s surveyor team operates on offshore and onshore industrial facilities to take accurate measurements. With ten years of experience in drilling and production platforms, refineries and petro-chemical plants, Urbica has been trusted by major firms such as Total, ENI, Perenco, Saipem, Technip and Ponticelli. With Urbica, discover how 3D laser scanning can improve revamping operations and day-to-day maintenance.

3D laser scanning for EPC companies

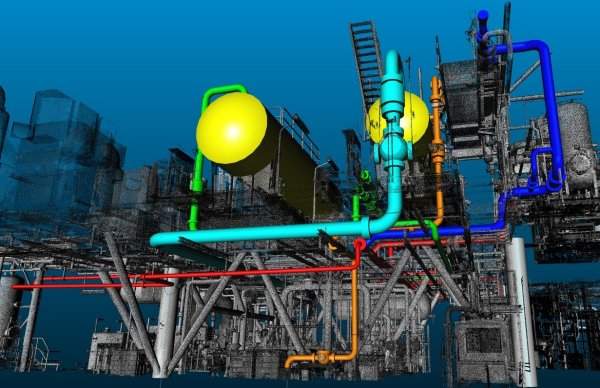

Thanks to 3D laser scanning, many EPC companies simulate heavy revamping projects directly in 3D. The files delivered by Urbica can be injected in most popular CAD software. Now, clash detection, pipe tie-in, de-bottlenecking or simple measurement checking can be done in an ‘as built’ 3D virtual model.

Engineers are able to verify the correct position of equipment, check piping diameter and visit the site from a distance, therefore simplifying maintenance.

Survey scanners for refinery and onshore production plants

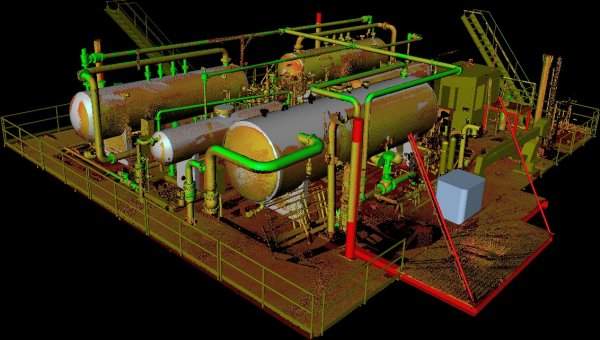

Land-based oil and gas facilities are big. From the refinery to the pipe rack, the distances involved run to hundreds of metres. Notwithstanding this size, surveying requirements also encompass more confined zones of the installation, where higher accuracy is required.

For this reason, Urbica has a scanner with a range of 300m, together with four more high-speed and accurate devices for measurements within a range from 20cm to 80m. As a consequence, time spent on-site can be optimised – and time is more than just money.

3D laser measurements for offshore utilities

Works executed on an offshore platform, FPSO or vessel are, to say the least, singular, remote in the extreme, subject to stringent safety rules and, as they are conducted in obvious confinement, can hardly be said to offer a congenial environment.

3D laser measurements are very advantageous and cost-effective because a simple team of one surveyor can measure in a few days what a team of five (electrician, instrumentation, piping, structure, process) engineers would in a couple of weeks.

Laser scanning provides an immediate solution to the major proportion of these obstacles: in just a few hours, Urbica can capture and compile a 3D model which is faithful to the actual conditions on site. It’s all there!

Once back from sites, Urbica generates 3D models with accuracy and exhaustiveness using the following:

Point cloud database for 3D laser scans

The point cloud is the first 3D end product which will be available for processing after the completion of a laser scan. A point cloud may contain millions, or even billions of points; at present, even the latest CAD software is not capable of managing spatial information in these quantities.

A number of software publishers are developing complementary solutions (as plug-in applications) for integration into professional software (Autocad, PDMS, Microstation, PDS, SmartPlant). There are also stand-alone softwares for the processing of these ‘point cloud’ files: Pointools, Realworks or Cyclone, for instance.

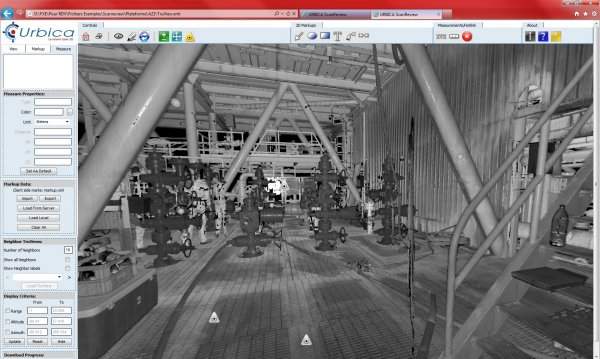

Internet distribution software for 3D laser scan results

ScanReview is a new facility for the internet distribution of the results of a 3D laser scan. This facility is intended to complement conventional distribution methods, and delivers added value to analyses.

Within a short time of on-site operations, this tool allows the free exchange and distribution of panoramic 3D images, the display of digitised view points, the annotation of equipment and the allocation of links to the relevant professional documents (notices, plans, photos, links, hypertext, etc.).

It is also possible to record, save and share 3D measurements with your colleagues via an intranet system or the internet. Using a simple http address, authorised users can access the same source of information simultaneously.

Software tools for 3D modelling of surveyed objects

Urbica uses dedicated software tools for the 3D modelling of surveyed objects in accordance with their current condition. Each structure, device or facility is reconstituted in graphic form for restitution in conventional CAD tools. Shape recognition on the basis of the cloud of points will provide the user with a 3D model or ‘3D pattern’ which is true to life, accurate and exhaustive. This modelling process may be completed on the basis of standardised ISO or AFNOR catalogues.

Urbica, a long success story

Upon the relaunch of Urbica in 1998, we were far away from imagining that our business – GIS data production – would soon take us into the world of 3D. Despite URBICA’s progression, its core business remains the same.

Urbica is essentially a people-based company. Our team of surveyors, topographers, computer specialists and sales personnel have human qualities which are appreciated by our clients. These qualities involve a combination of expertise, professional rigour, innovation and ingenuity. It is for these reasons, no doubt, that clients keep coming back to Urbica.