Transvac is a privately owned ejector specialist company formed in 1973. It has supplied thousands of ejectors over the last 40 years, with designs that are based on both theoretical and empirical knowledge within a range of technologies. The company’s knowledge and experience is invaluable in enabling it to produce ejectors and ejector systems using the very latest design and construction techniques.

As both a designer and a manufacturer of ejectors, Transvac has full in-house control over process and mechanical design, supply of raw materials, manufacturing, scheduling and testing. All products are custom-designed to suit the process and mechanical requirements of each application to ensure maximum operating efficiency. Ejectors are ideally suited to many oil and gas industry applications, including flare gas recovery, optimising production, restarting shut-in wells and replacing first-stage compressors.

Fluid pumping and pressure boosting

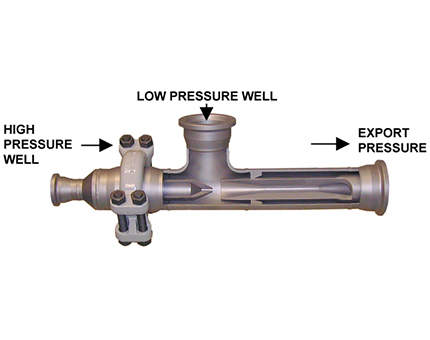

Ejectors (also referred to as surface jet pumps, eductors or venturis) provide a simple, robust and reliable method of pumping and boosting the pressure of fluids. The operation is based on Bernoulli’s principle: by increasing the velocity of a fluid as it passes through the nozzle, a low-pressure region is created within the ejector. The region entrains and compresses the secondary LP stream; as the combined HP and LP streams pass through the ejector’s diffuser section, the velocity decreases and the pressure is regained, resulting in an intermediate pressure which lies somewhere between the LP and HP inlet pressures.

Flare gas recovery solutions

Traditionally in the oil and gas industry, waste and surplus gas has been disposed of by flaring into the atmosphere. Today, this process is becoming increasingly unacceptable, as the industry progresses towards conserving energy and eliminating greenhouse gas emissions.

The demand for equipment that can safely and economically compress waste and surplus gas back into the production process is rapidly increasing. Ejectors are ideally suited to this application, because they employ either the available high-pressure gas or liquid energy to entrain and compress waste and surplus gas to a pressure where the gas can be recovered into production or used as fuel gas.

Enhanced recovery solutions

Transvac ejectors provide a proven, simple and reliable technology for boosting production of low-pressure gas wells, by lowering the wellhead pressure using existing energy sources. For instance, HP gas energy normally wasted across a choke valve or compressor recycle valve could be used.

Produced water and sand management

Transvac ejectors are an ideal method of transporting sand slurries from separators or cyclones as part of a de-sanding / sand washing system for the oil and gas and allied industries. Accumulated sand is normally fluidised to ensure it will flow, using jets of water by-passed from the motive water supply prior to entering the suction port of the ejector.

Transvac sand slurry ejectors are manufactured as standard with ceramic motive water nozzles and ceramic throat inserts to resist abrasion.

Custom-designed ejectors

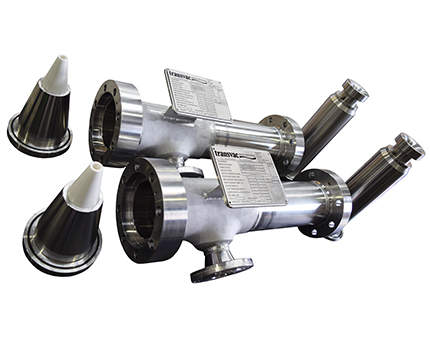

We understand that production is not always predictable. Conditions change over time and facilities need to be able to deal with this. Ejectors are fixed-design devices, and each Transvac ejector is custom designed to perform at specific operating conditions.

The company’s patented Universal Design ejector comprises an external pressure-retaining shell into which two replaceable components are fitted which give the ejector its operating characteristics: the nozzle and the diffuser. They can be easily changed out to give the ejector different optimum operating characteristics.

Therefore, as well conditions change over time (or flaring conditions for gas recovery applications), the internals can be replaced with new ones which are more suitable. By changing out the internals, high performance efficiency can be maintained over the lifetime of the unit, maximising gas recovery from the LP wells and the field (or maintaining optimum gas recovery for FGR applications).

Transvac research and development

Transvac officially opened its state-of-the-art R&D facility in April 2010 to develop new ejector technology for the oil and gas industry and to offer performance testing of systems and products.

New development projects are primarily targeted at oil and gas applications including subsea processing, flare gas recovery, sand management, produced water treatment and production boosting of low-pressure wells. New ejector designs are also under development for the nuclear, biofuel, chemical and wastewater industries.

The R&D facility includes high and low-pressure equipment for handling water, gas, multi-phase and slurry. Test programmes are supported by CFD studies and include fundamental university research.