Kane Energy Services (KES) is a supplier of flare systems for offshore platforms, and floating production, storage and offloading (FPSO) vessels.

Smoke-free sonic flare burners

KES designs and produces a wide range of utility, single-point and multi-point sonic flare burners for offshore use.

Utility flare burners are used to burn lighter molecular weight waste gases at low pressure and in situations where smokeless flaring is not necessarily a concern. This type of burner is simple in design and can be used for gas exit velocities of up to Mach 0.75.

Specifically used where high system back pressure is acceptable, single-point sonic flare burners are designed to effectively dispose of lighter molecular weight waste gases using pressure as the motive force, up to Mach 1 exit velocity.

This type of burner is typically installed for blowdown operations, where a very short time period is available to dispose of inventory and where smokeless requirements are not so stringent.

Multi-point sonic flare burners also dispose of waste gas using pressure, yet are designed to provide a short stable flame, which is less affected by wind.

They can be applied in facilities where a long flame length cannot normally be tolerated, on offshore production and drilling platforms. This type of burner can provide smokeless flaring of heavier molecular weight gases through inertia.

Electronic pilot burners

Incorporating a high-energy electronic ignitor into an energy-efficient pilot burner, the Kane High-Energy (KHE)-7000 pilot / ignitor is the result of decades of pilot testing for high wind areas and effective re-ignition sequences.

The KHE-7000 uses a 10,000vac ignition device to ignite the pilot burner, once the pilot flame is proven via the internal temperature sensing module, the ignitor goes into standby mode, re-igniting the pilot should it extinguish. Re-ignition of the pilot will continue at regular set intervals until the temperature sensing module has again reached the set operating condition.

The KHE-7000 can be lowered to the platform work level for maintenance and inspection by way of a unique rail system, allowing for repairs and preventative maintenance without the need for platform shut-ins. Control panels are available for installation in all electrically rated hazardous areas, in either AC or DC voltages, with solar-charging systems for remote flare tower operation.

Kane’s high-energy pilots are manufactured with the highest quality corrosion and heat-resistant materials, ensuring a long service life, reduced maintenance and the utmost in reliability and availability.

About Kane Energy Services

KES has more than 30 years of specialised expertise in the design and manufacture of flaring products specifically designed to satisfy stringent offshore flaring requirements, resulting in high-performance, built-for-purpose products of uncompromising quality and workmanship.

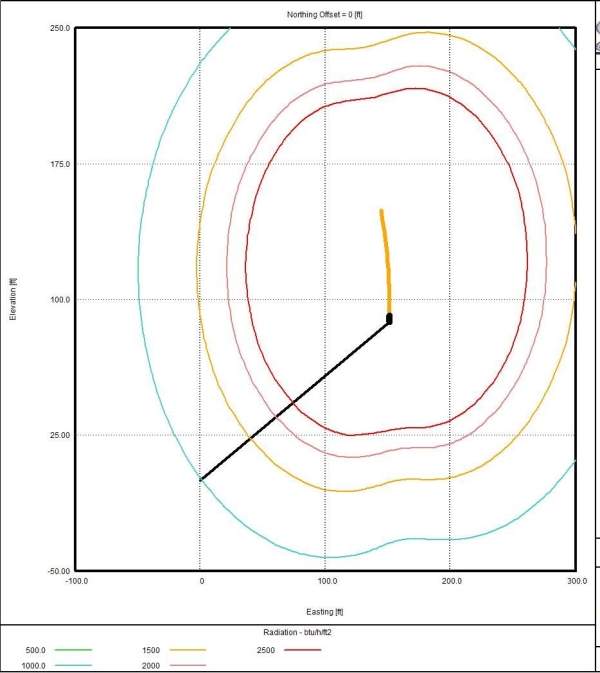

KES uses recognised industry standard software in all aspects of flare system design, while following the current guidelines of API-521, API 537, local environmental requirements and specific project details from the client.

Manufacturing of Kane Energy Services products is continually monitored through very rigid quality control procedures, ensuring the best possible built-for-purpose equipment in accordance with the quality management standards of ISO:9001, ASME Section VIII / B31.3 and the CSA Canadian Electrical Code.