IRM Offshore and Marine Engineers is the flagship company of the IRM Group, founded in 1964. Over the last five decades IRM has established itself as one of the most reliable names in the offshore and marine industry. It is highly dedicated to designing and manufacturing critical offshore platform installation aids and various fenders for ports across the globe.

IRM is an IMS-certified company covering ISO 9001:2008, ISO 14001:2004, OHSAS 18001:2007. IRM has also acquired a Manufacturing Capability Certificate from Germanischer Lloyd, Hamburg, for all the products that it manufactures. IRM provides custom-built solutions to suit specific applications required by its clients.

IRM has substantial experience and expertise in designing, manufacturing and supplying offshore platform installation aids and protection systems such as barge bumper assembly, shock cells / absorbers, diaphragm closures, grout seals / packers, pile closures, pile grippers, boat landing rub-strips, jacket leg rub-strips, leg mating units for float overs, shear fenders, etc. IRM also manufactures’ various solid fenders for maritime applications such as cell fenders, cylindrical fenders, IV fenders, element fenders, key hole fenders etc.

Manufactured products are supplied worldwide to various offshore oil companies and EPC contractors that build offshore platforms. IRM also provides full technical and aftersales services that help to totally satisfy our clients’ requirements. In the recent past, IRM has supplied critical platform installation aids to J Ray McDermott, Saipem, NPCC, Kencana HL for their clients like Aramco, ADMA, Petronas, Lukoil and ONGC.

Diaphragm closures, grout seal and packers

DIPTI diaphragm closures are critical installation aids for launching offshore jackets. Diaphragms closures’ primary role is to withstand hydrostatic pressure and act as a flexible barrier to seal the jacket legs, thus enabling the platform to float in the sea, facilitating its movement and positioning onsite after launching.

DIPTI mechanical seal type grout seals are a superior alternative to inflatable grout packers. These grout seals do not require any inflation system, thus reducing installation cost and offer a perfect sealing solution. Grout packers may fail due to non-inflation, though however rare it may be. However, dual lip grout seal assembly, manufactured by IRM, is extremely reliable since both the sealing rings, as well as the two lips, will each cling on to the pile, thus making it failure-proof.

DIPTI diaphragm closures and grout packers are available from 24in OD to 144in OD pile, and customised sizes can also be designed. DIPTI grout seal assembly can also be supplied with suitable mud wiper to prevent mud penetration from the bottom of the jacket. IRM manufactures inflatable grout seal packers on request of the customer, according to their given dimensions.

Jacket leg pile gripper

DIPTI pile grippers are a unique engineering innovation for the installation of offshore jackets. After driving pile through them, pile grippers are employed for the leveling of jackets and also for restricting any movement of the jacket during grouting.

DIPTI pile grippers are available for 42in to 96in pile size. IRM also supplies hydraulic power pack units with all controls for the actuation of grippers.

Shock cells and barge bumpers

DIPTI DSA series shock absorbers are designed with telescopic steel pipes (for easy installation onto the steel structures), and high modulus rubber annulus to absorb loads from multiple directions. The concentric pipes, when bonded together with rubber under a controlled environment, result in a versatile energy absorption assembly for offshore structures. DIPTI DSA series shock absorbers are available in six different models.

DIPTI barge bumper systems are a unique and technically superior protection system for offshore platforms worldwide. They accommodate berthing for very high tidal variations. They are capable of absorbing both axial and lateral loads, thus giving them a distinct edge over any other platform protection system.

Barge bumpers and shock cells manufactured by IRM are used extensively in various platforms worldwide.

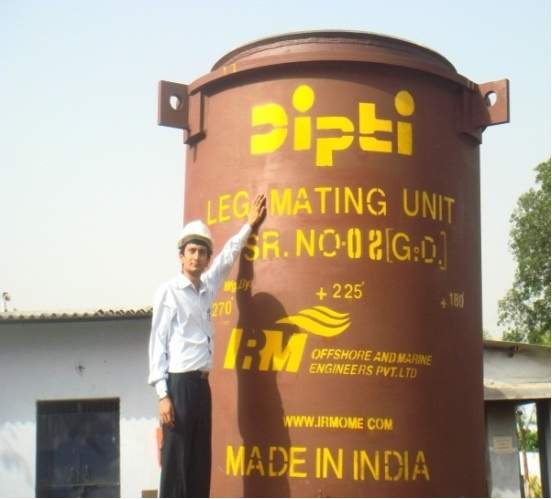

Leg mating units

DIPTI leg mating units are designed for the smooth installation of the top deck on the jacket legs. They are designed to take lateral misalignment, jerks and vertical loads. The deck is lowered on these mating units and they smoothly transfer this load to the structure without jerks and impact loading.

DIPTI leg mating units are available in two different designs. Custom-made leg mating units can also be designed and manufactured as per specific requirements.

Shear fenders and boat landing rub strips

Shear fenders come in two types: the DSF series and the DSQ series. Both are designed to take heavy loads of barge bumpers / boat landing structures axially and at the same time to absorb berthing energy laterally.

DIPTI DRS series rub strips are made of solid low friction rubber for rugged use. They are used to act as a buffer between a boat landing of an offshore structure and the vessels that come in contact with them. The character of these rub-strips is extremely rugged, reliable and maintenance-free.

Pneumatic fenders

DIPTI DPN series pneumatic fenders are manufactured to ISO 17357: 2002 with various internal pressures. The carefully crafted high abrasion-resistant external layer and internal rubber layers make IRM’s pneumatic fenders extremely reliable and ensure a trouble-free long life.

These fenders offer excellent energy absorption capabilities and have linear load deflection characteristics. They are very easy to install, remove and handle for various applications.

The DIPTI pneumatic fenders are available with four different variations such as CTN type (chain and tyre-net), sling type and RIB type. DIPTI DPN series pneumatic fenders are available in wide range from 500mm diameter to 4,500mm diameter and in 1,000mm length to 12,000mm length as per specified requirements.