Himech Equipments is a leader in the design of oilfield equipment. Himech Equipments specialises in supplying well testing equipment such as flare and burner booms and surge tanks, and cementing equipment such as batch mixers, cement carriers and storage silos.

Burner booms

Himech burner booms extend ‘Sea Dragon’ crude oil burners and gas flares at a set distance from an installation. This allows produced hydrocarbons to be flared safely, moving the radiated heat away from the installation.

Himech flare booms are a portable U-shaped truss assembly. The King Post attaches to the rig structure and is braced with three tieback struts. Vertical suspension cables and horizontal wind stay cables support the boom, so a rig crane is not needed for support.

Himech burner booms have been installed with three head ‘Sea Dragon’ burners, allowing division of the flame into three independent smaller flames. This increases the amount of air available for combustion, provided by the injection of air into the mixing chamber as well as ambient.

Flare booms

Available in 60ft, 90ft and 120ft lengths, Himech burner booms feature a modular design that allows for easy upgrading. The lightweight structure of the boom reduces the crane capacity requirement and simplifies the installation process.

A U-shaped configuration helps provide added security for personnel using the boom. A boom attachment point at the kingpost easily accepts the boom into U-shaped slots, thereby further cutting the installation time.

U-shaped burner boom assembly

The burner boom assembly features a wide range of components. The burner head assembly consists of three burners, cone type outer covering for burner, water spray line, set of heat resistant valves and a gas flow line. The pilot ignition system uses LPG / propane gas for the Sea Dragon burners. The system works on 120V / 220V AC and 50Hz / 60Hz power supply.

A complete manifolding arrangement of piping and valves facilitates the selective use of any one or several of the burners at a time to achieve more efficient disposal. The U-shaped design of the boom structure supports burner heads, provides safe walkways and supports all piping for oil, gas, water and LPG / propane.

The heavy-duty king post assembly can be attached to rig structures and braced with three tieback struts. The burner boom is attached to the king post at the rotating pivot point and is supported by vertical suspension cables.

Technical data:

- Length: 60ft (18.3m) / 90ft (27.4m) / 120ft (36.6m)

- Weight: 4,400kg (9,680lbs) / 6,200kg (13,640lbs) / 8,100Kg (17,820lb)

- Burner capacity: 10,000BPD

- Gas flaring capacity: 1.8 million cubic meters per day

- Air requirement: 300ft³ per minute

- Working pressure: 1,440psi

- Test pressure: 2,175psi

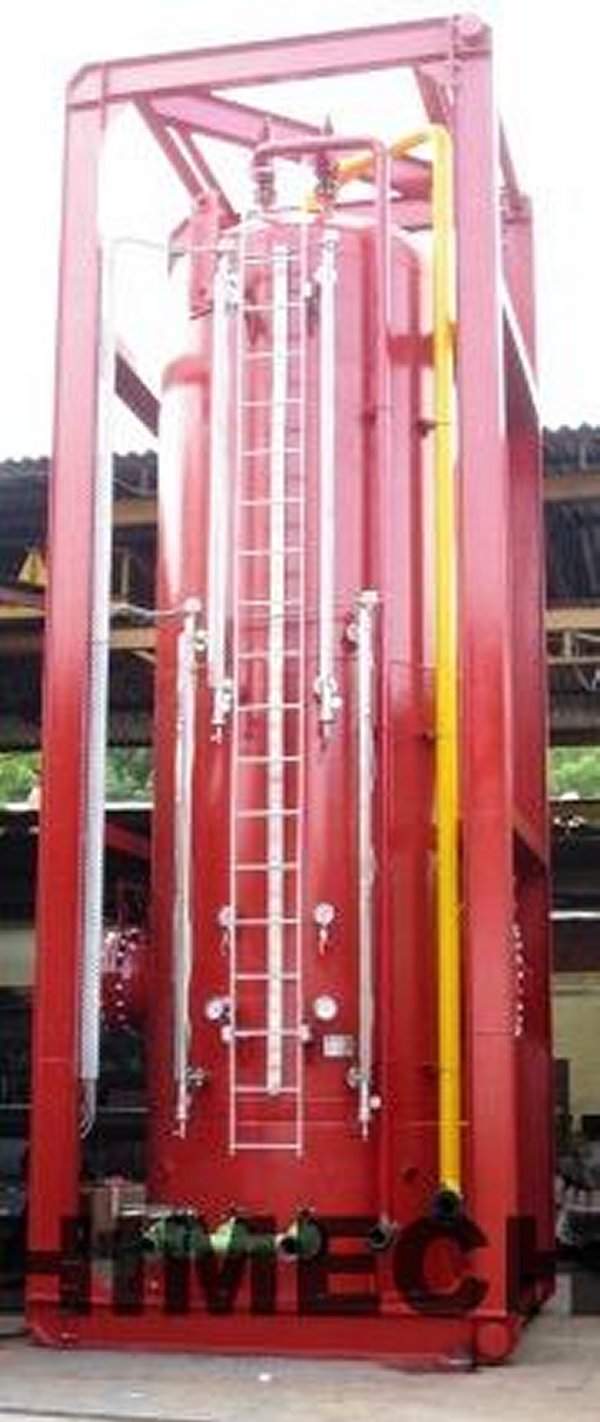

Surge tanks

Surge tanks are using during well test operations as a secondary or additional stage (two, three, four phase) of separation and metering. When longer retention times are required for effective separation a surge tank is a very good alternative. Surge tanks can also replace gauge tanks when H2S is present.

Himech’s surge tanks come complete with piping, flanges, valves, instrumentation union connection and magnetic level controllers with high/low level alarm.

- Capacity: 100 BBL (twin compartment)

- Working pressure: 75/150/250psi

Batch mixers

Himech’s batch mixing system can be used for all cement, flush and spacer mixing operations. The batch mixing tank features agitators to allow the batch mixing of cement for plug and squeeze and allied cementing jobs. Both mechanical and hydraulic batch mixers are available, and come supplied with control console, piping valves and hose connectors. Optional equipment includes:

- Ground mixing system

- Slurry mixing system with recirculating loop

- Surge tank

- Hoppers

Bulk cement carriers

Himech cement carriers are available in either truck-mounted or trailer-mounted models. They can be manufactured with or without surge tank as per requirements. All Himech cement carriers work on dense phase technology, ensuring a smooth and constant flow of cement.

- Capacities for truck-mounted models – 10 MT / 12 MT / 15 MT and 20 MT

- Capacities for trailer-mounted models – 20 MT, 30 MT, 35 MT and 38 MT

Himech’s mobile bulk cementing unit (MBCU) is used to transport dry cement from bulk handling plants and is designed to be directly hooked up for cementing jobs at the drill site with the cementing unit. It comprises a powerful screw compressor, coded pressure vessel, surge tank, piping and valves, and provides a constant rate of discharge.

- Capacities – 10 MT / 12 MT / 15 MT and 20 MT (customisable to client requirements)

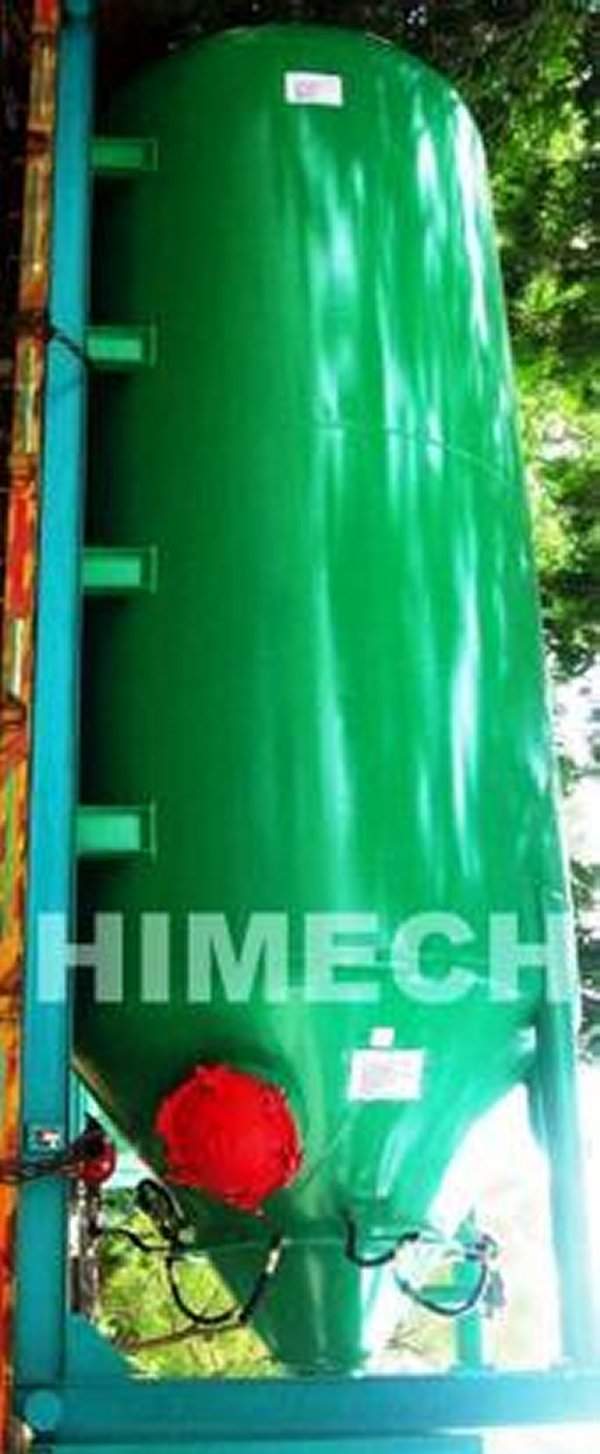

Cement storage silos

Vertical silos are ideal for cement storage applications in both onshore and offshore drilling operations. Himech field silos boast a range of innovative features, including stable height to weight ratio, low ground pressure when fully loaded, efficient aeration system, and oversize discharge piping for high-speed unloading. Himech can also supply silos which are custom made according to the client’s capacity requirements.

- Capacities – 50 T / 100 T / 120 T / 150 T/ 200 T