FoundOcean is a world leader in subsea and offshore cementing for the global energy construction industries. Its primary business is fixing structures to the sea bed by foundation grouting. FoundOcean also provides structural repair services for subsea and offshore structures, as well as pipeline and cable support and protection services.

FoundOcean, now a privately held company, was founded in 1966 and is headquartered in the UK. Its specialist subsea and offshore engineering equipment is located for rapid deployment in key energy producing areas of the world, including Europe, the Gulf of Mexico, South East Asia and the Middle East.

Structural pile grouting

FoundOcean’s involvement in the offshore industry dates from the Umm Shaif and Zakum oil fields in the 1960s. The company was the first in the world to develop the process of offshore grouting, a process which is now being used worldwide on a vast number of subsea installations.

This experience was transferred to the North Sea in the early 1970s for the installation of the BP Forties platforms. Since that time, FoundOcean has worked on the successful installation of numerous jacket and template structures in all oil producing areas of the world.

FoundOcean is the leader for pile grouting jacket structures with over 45 years’ experience. It has developed a unique recirculating jet mixer technology to pump grout faster and set harder without harsh chemicals.

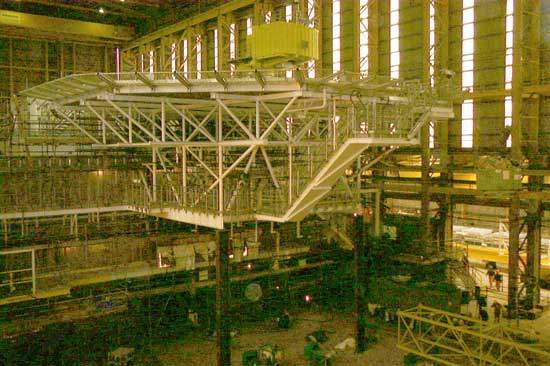

Ballasting and underbase grouting for offshore structures

Underbase grouting is used to provide evenly distributed support to gravity-based offshore structures. FoundOcean gained initial experience in underbase grouting and ballasting on the Thistle SALM installation project in 1978. The scope of work included pumping 2,000t of hematite into the base of the structure.

Offshore structural repair and strengthening

Repairs and strengthening for offshore structures may be required for a number of reasons. The most common include fatigue, regulation amendments, collision damage and connecting additional members. FoundOcean provides grouted clamps, stressed grouted clamps and grout-filled tubular to solve each of these issues.

Pipeline support and stabilisation

Pipelines and structures need supporting over stretches of uneven seabed and ravines – this is called free span correction. FoundOcean is your single-source for the design, manufacture and installation of all types of fabric formworks. In fact, it holds the record for deploying the deepest fabric formworks at a depth of 1,224m.

The fabric formworks are a flexible shuttering constructed from woven fabric, which is filled with grout in-situ. The final shape of the support is defined by the shape of the fabric formwork. Fabric formworks may also be used to raise a pipeline or structure by jacking to a desired elevation.

Grout density monitoring systems

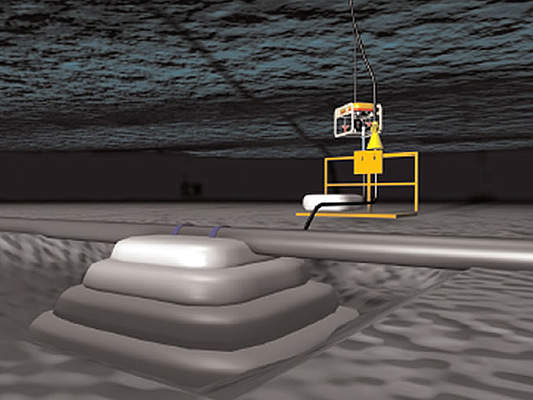

Grout density at the skirt pile is measured by an ROV-deployed densitometer, which is inserted into the grout overflowing at the top of the sleeve. The ROV-based system operates on the principle that the radiation emitted by a source and received by a detector is attenuated by the material flowing in the space between the two. The relationship between the degree of attenuation and the material density may be established by the calibration of the density probes.

FoundOcean provides advice on all types of grout monitoring systems, and also designs and constructs the necessary monitoring equipment to suit all types of platforms and templates according to client requirements.

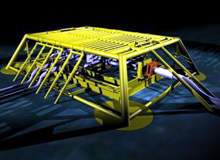

ROV grout connectors

FoundOcean’s unique ROV grout connectors are specifically designed for underwater connection of grout lines. For over 20 years these connectors have been used worldwide in various water depths to reduce onshore fabrication costs and offshore installation costs by eliminating the need to install and remove temporary pipework. This system can be used for both platform and template installation.

Pipeline and cable protection technology

Tides and currents cause erosion of the seabed adjacent to solid objects. This erosion is known as scour and affects the stability and integrity of pipelines, cables and subsea structures.

ScourMat stops erosion and helps to reinstate the seabed around the structure. The ScourMat fronds open out to form a fan-like array, which slows down the local current and causes suspended particulate matter to settle. Over time, the ScourMat becomes engorged with sand and sediment, reinstating the seabed with natural components. This fibre-reinforced bank will then resist further erosion.