ZOMO specialises in medium and heavy-steel fabrication and mechanical constructions for all production activities.

The business opportunities of the emerging oil and gas sector have led ZOMO to develop its offshore operations.

ZOMO has great experience in medium and heavy-steel fabrication, allowing the company to satisfy the demands of a varied and international client base.

Fabrication in accordance with international regulations

ZOMO works and guarantees the quality of its products through a continuous commitment to qualitative standards of company certification. It applies management regulatory systems, such as health and safety, quality, environmental and energy.

In addition, the company is certified under welding standards, thus guaranteeing qualified WPQR and WPS welding procedures. This compliance to international law and essential manufacturing processes is a must for ZOMO, which seeks to present itself as a reliable and efficient partner under all aspects at the international level.

Material supply for offshore constructions

ZOMO supplies a complete service, from material supply to final assembly. The main types of materials used for huge steel structures are S235JR, S235JO, S355JR and S355JO, as well as WELDOX 700/900/110 and HARDOX. Furthermore, the company’s supply can also include accessories (such as screws, bearings and tubes) and commercial profiles.

All construction material is certified in compliance with applicable CE regulations, while all personnel are highly qualified and certified with welder licenses for each welding type.

Fabrication of offshore structures

In the offshore industry, ZOMO supplies the following:

- Frames for the construction of platform decks

- Cranes and beams for the construction of lifting and supporting systems

- Drilling and extracting bores

The company’s experience in the offshore sector extends to the fabrication of ships’ hulls, floating barges and support structures for oil and gas operations.

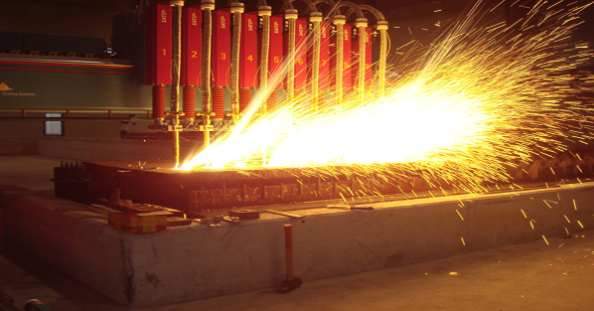

The company has the necessary facilities to cut and mould the sheet to customer specifications using plasma cutting, oxy cutting and laser cutting. Furthermore, it offers calendering and bending services.

In the assembly phase, the company applies MIG/MAG and TIG welding processes, guaranteeing non-destructive dimensional tests (VT, MT and RT) so that all the sections correspond perfectly at the moment of assembly.

For the machining of frames, cranes and other medium-heavy mechanical constructions, ZOMO carries out operations in part internally and in part using its external partner, Rössl e Duso.

ZOMO is the ideal partner for the fabrication of medium and heavy structures. It is equipped with overhead travelling cranes that lift up to 50t-60t. This allows easy materials handling for fabrication. ZOMO’s ability to fabricate is very competitive; it has manufactured structures of great size and up to 150t in weight.

Surface treatments for offshore operation

By customer demand, ZOMO offers heat treatments, such as stress relieving and normalising, in order to relax the material’s ribs. It has a sandblasting machine with a continuous tunnel to remove the impurities on the material’s surface caused by processing.

ZOMO also offers the service of liquid painting, including epoxy primer cycles and marine cycles depending on the customer’s demands, in order to protect the structures from corrosion caused by continuous contact with saline water.

All these services are performed ‘in loco’, so that a network of subcontractors is not necessary, thus optimising fabrication times and reducing costs.

About ZOMO

ZOMO was established in 1990. The main production plant is located in the province of Treviso in the north of Italy, and is close to arterial highways, port areas and railway junctions. ZOMO also has a branch in Slovenia and another in Romania. ZOMO aims to expand into the emerging oil and gas sector at a European and international level.

Do not hesitate to contact ZOMO using the form below for more information or business enquiries.