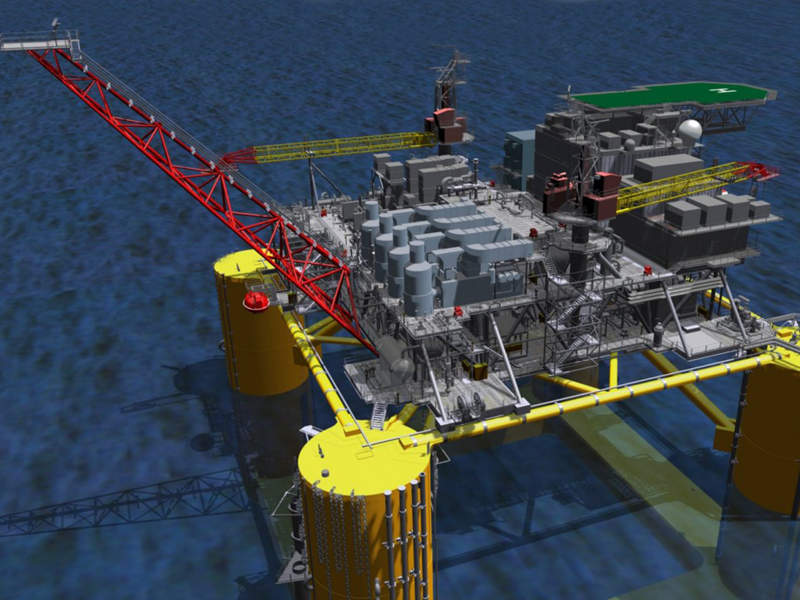

Kidder specialises in fabricating and welding services for the oil and gas, commercial diving, petrochemical and power generation industries.

The company also provides carpentry, electrical, engineeing and waterjet cutting services.

Metal welding and fabrication services for the oil and gas sector

Kidder is known worldwide for its quality turnkey services in carbon steel, stainless-steel and aluminium. The company holds several welding procedures in a vast range of metals such as, A-36, A572, API 2H Gr. 50, and a multitude of other materials of carbon steel.

Kidder also has many approved aluminium welding procedures that cover various material grades, including 5052, 5086, 6061, in addition to 304, 309, 316 stainless-steels.

The company holds dual DNV-approved welding procedures in carbon steel and aluminium, as well as CNC press brake and CNC shear capabilities to help with accuracy and efficiency to streamline large and small quantity projects.

Kidder also has rolling / punching capabilities to accommodate with cage ladders and clamps, in addition to in-house sheet metal press brakes and shears.

Waterjet cutting services

Waterjet services enable Kidder to cut a wide variety of materials using a high-pressure jet of water with or without an abrasive substance. They also give high-accuracy cuts without using high temperatures or compromising the integrity of the materials being used.

The company’s two jets can cut any material grade, as well as thicker materials if needed.

Load testing services / NDT inspection

Kidder provides load testing services of all shapes and sizes, ranging from vertical (175,000lb) and static (compression) testing.

The company offers fully traceable documentation for every load test, which assures clients that the device or lifting appliance has been successfully tested up to the Gulf of Mexico standards from DNV and beyond, as well as third-party inspection services (NDE) on any project where testing is required.

Kidder is a certified load testing facility used by major companies such as Oceaneering, Shell, Schlumberger, BP and BHP Billiton.

Machining and wire electrical discharge machining (EDM) services

Kidder uses the latest computerised numerical control (CNC) machines, CAD / CAM, and solid modelling networked software for mechanical design and manufacturing in order to deliver high-quality parts built to the client’s specifications.

The company’s state-of-the-art equipment enables the firm to produce one-off prototypes or accurate production runs.

About Kidder

Kidder is an independent company that has been in business more than 30 years, offering welding serves and high-level provisions.

Kidder aspires to deliver projects on tight schedules at competitive prices. By relying on its skilled and highly trained team, and high levels of expertise and knowledge, the company ensures that even the most demanding requirements are met in fabrication and welding projects.

Through the acquisition of advanced technology and equipment, and a substantially more efficient and productive facility, and a strong team, the company aims to make any project a complete success.