Buitendijk Techniek offers design, mechanical engineering and fabrication services for access gangway systems, SHF cranes and multi product hose towers. A sister company, Global Bearings Services, delivers all kinds of slewing bearings.

Access gangway systems

Buitendijk Techniek designs and delivers bespoke gangway systems for access towers, telescopic gangways with self-levelling steps, electric or hydraulic cranes, fire fighting equipment, control cabins, explosion-proof execution (Ex) applications and Ex radiographic remote control systems. These can be made fully-automatic if requested.

Buitendijk Techniek can manufacture explosion-proof installations according to European (Cenelec / ATEX) and American (NEC / UL-codes / ATEX) standards. Ex equipment can be delivered with Ex radiographic remote control or the required classification.

SHF cranes

Buitendijk Techniek designs and produces manual, electric, hydraulic and diesel-driven cranes for a number of varied applications (including explosive), for any type of ship, jetty or hose tower.

The company has special test equipment for complete cranes up to 500t, and can carry out factory testing, inspection and full acceptance testing at an onsite test bed prior to shipping.

Comprehensive customer support, in addition to spare parts, servicing, installation, commissioning, repair and rebuild, preventive maintenance, retrofits and upgrade services are also provided on request.

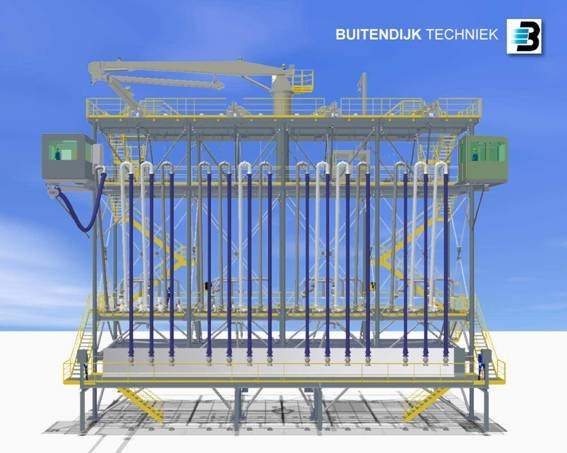

Multi-product hosetowers

Buitendijk Techniek has had experience working with cranes on jetties since 1987, which are mainly used for hose and store handling.

More recently, the company has successfully participated in the design, engineering, procurement, installation and commissioning of several hose towers.

Slewing bearings

Buitendijk Techniek’s sister company, Global Bearing Services, supplies a large variety of slewing bearings that can be designed to client drawings.

Global Bearing Services supply cross roller, three-row and single and double-row four-point contact bearings in diameters from 100mm-8.5m, with or without internal or external gear.

Mechanical engineering services

Buitendijk Techniek develops client specifications to produce a variety of machines, apparatus and installations. This is made simple by the company’s technically skilled and motivated staff and top-of-the-range facilities and software systems.

Buitendijk Techniek develops and produces a wide range of welding positioning equipment, including:

- Rotators

- Positioners

- Columns and booms

- Clamping benches

- Hoisting manipulators

Inspection, repair and maintenance services

Buitendijk Techniek inspects, maintains and repairs cranes and equipment, either made by the company itself or that of colleague companies.

The company’s inventory of spare parts has been chosen by experienced engineers and service co-ordinators, in order to ensure the best quality supply of and the longest possible lifecycle.

All original drawings and parts lists are frequently accessed, while each new crane is delivered with a recommended spare parts list. Buitendijk Techniek also supplies all required certificates. Our approved vendor list is based on ISO 9001.

Remote access for installations

Most equipment can be optionally executed with remote access facilities, so our engineers can access the installations online. This means that problems, system checks and software upgrades can be resolved in real time, eliminating travel time and ensuring quick service.

Quality assurance

Buitendijk Techniek procedures guarantee quality and are set down in our quality assurance manual.

The company’s quality management system has been approved by Lloyds Register of quality assurance; approval certificate no. 661719.

All our products can be delivered on demand with approval certificates from the major classification societies.