Aubin Group supplies and develops oilfield chemical solutions to the oil and gas industry.

High-quality oilfield cement additives for offshore applications

Aubin offers a wide range of liquid and powder cementing additives to ensure that slurries are pumped with the necessary physical properties for each cement job.

The company also develops cement retarders, fluid loss additives, dispersants, spacers, defoamers and anti-gas migration chemicals.

Specialising in oilfield chemistry, Aubin supplies high-performance cement slurry additives, stimulation chemicals, well-acidizing additives, fracturing additives, pumpable pipeline protection gels, pipeline pigging, drilling waste management, subsea lifting, decommissioning chemicals, and gas production enhancement foamers and solutions.

Acidizing additives for the enhancement of well productivity

Aubin’s speciality chemicals include acidizing additives developed to enhance well productivity and protect valuable tubulars.

The company offers a range of high-performance acid-corrosion inhibitors that can withstand temperatures of up to 350°F while protecting downhole tubing and equipment from acids used to enhance oil production.

Artificial lift foamers for liquid-loaded gas wells

Chemicals for enhancing oil and gas production can extend the life and value of hydrocarbon wells.

Aubin foamers achieve gas well deliquification in high-condensate loaded wells to restore and increase production in liquid-loaded wells or wells with decreased production.

Chemical wash drilling fluid additives

Aubin supplies a range of fluid additives for post drilling to clean, protect and prepare wells for production.

The company’s CW-20 and CW-12 chemical wash solutions increase well productivity by cleaning mud residues to enable a secure bond between cement and the wellbore casing.

Process oil drilling fluid returns at source

Oil slop breakers maximise oil phase recovery by treating emulsions and drilling slops at the source, which reduces transportation and processing costs, as well as environmental impact.

Flexible pigs for challenging pipelines

EVO-Pigs are flexible, gel pigs that can overcome vulnerable, challenging, multi-bore onshore and offshore pipelines.

In comparison to mechanical pipeline pigs, EVO-Pig is a risk-free solution for treating or cleaning pipelines that can tackle bends and changes in diameter to return to its original size.

Pipeline gels for effective pipeline maintenance

Aubin has a suite of pipeline gels for pipeline commissioning, maintenance, cleaning and decommissioning.

Suitable for debris pick-up, pig lubrication and hydrotest operations, the company’s pipeline gels have been tested and approved under the Offshore Chemical Notification Scheme (OCNS).

Buoyancy solutions for subsea placement and lifting applications

Aubin’s pumpable subsea lifting technologies offer the oil and gas industry a new method of placing, moving and lifting assets and equipment on and around the seabed.

Sealing and plugging pressure retaining impermeable barriers

The company’s innovative chemical solutions can often be applied in inaccessible locations, including the inside the leg of a platform, and can form pressure-retaining impermeable barriers.

Proven chemical solutions for decommissioning operations

Aubin is a provider of proven solutions for decommissioning old or expired offshore and onshore structures.

From well plugging and abandonment (P&A) using tailored cement additives, to pipeline pigging using EVO-Pig, Aubin offers numerous solutions that make decommissioning projects low-risk, cost effective, environmentally safe and successful.

About Aubin Group

Aubin has been supplying high-quality cement additives to clients in the oil and gas industry for more than 25 years, and has an experienced team of chemists who can formulate the appropriate cement slurry for specific applications.

The company has manufacturing, stocking and office locations in the UK, the US and various regions in the Middle East.

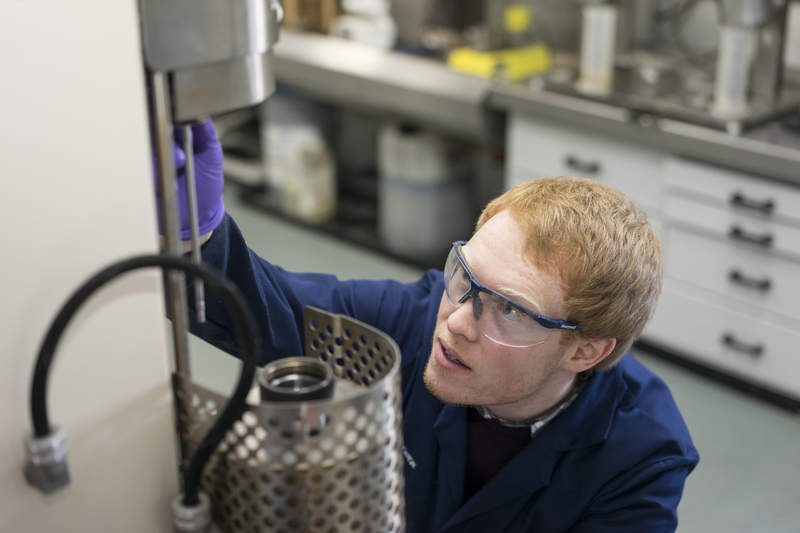

Aubin has a state-of-the-art independent cement testing laboratory at the company headquarters in Aberdeenshire, the only one of its kind in the UK. Last year, the company invested 25% of its turnover back into R&D, to continue the development of innovative new chemical solutions.