Versabar is an integrated engineering company, providing a full range of services and innovative solutions for a variety of industry challenges.

The firm performs detailed engineering and design, fabrication, and system integration testing, and its trained onsite technicians operate the equipment once it is deployed to ensure successful completion of the project.

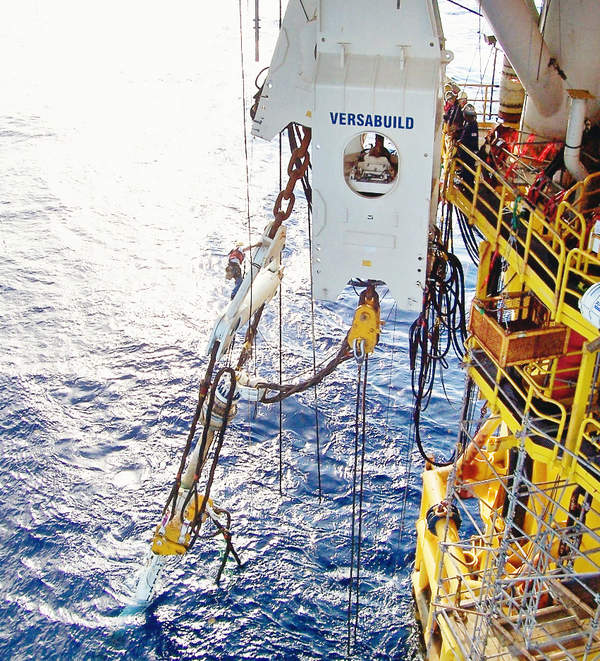

Riser and umbilical installations for the offshore industry

Versabar provides custom hydraulic winch-based systems for riser and umbilical pull-ins on jackets, spars, floating production storage and offloading (FPSO) units and semi-submersibles.

The company has installed more than 150 risers and umbilicals worldwide with loads up to 650t. For higher loads, the firm transitions to custom chain jack solutions. Versabar engineers and furnishes a complete installation system from basic functional specifications, outlining riser and umbilical weights and furnishing platform layout drawings.

Versabar’s scope of services includes detailed engineering and design of the pull-in system, equipment lay-out accounting for all platform interface issues, interfaces with the pipeline / umbilical installation contractor, fabrication of beam packages and turndown sheave support structures.

Complete system integration testing and proof loading is also supplied, along with installation and operation of the pull-in equipment.

Flex joint and stress joint replacement

Versabar provides custom engineered winch packages for application in the removal and installation of flex joints and stress joints on risers from onboard platforms without using a derrick barge and custom rigging equipment needed to support the repair operation.

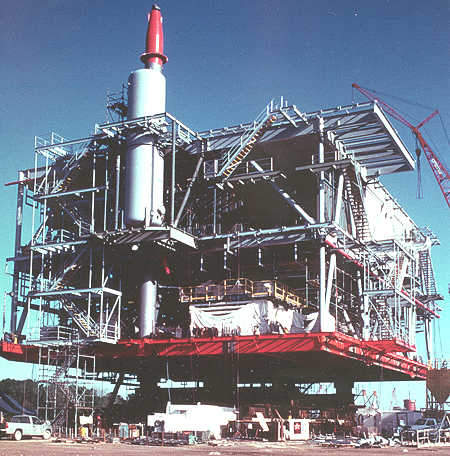

Platform-based lifting solutions

Versabar’s comprehensive lifting, rigging, engineering, fabrication and operations background combined with a diverse inventory of equipment that includes rigging, winches, hydraulic jacks, air casters, skidding systems, and other specialty lifting equipment, provides Versabar with the tools necessary to handle platform-based installations, upgrades, and repairs. Versabar works with limiting design parameters, such as tight spaces, to deliver platform-based lifting systems where utilizing a crane would not be a viable solution or the use of a crane barge vessel is too expensive.

Custom hydraulic cylinder-based lifting and pulling systems

Challenged by an offshore operator to increase the storm air gap on two eight-pile Gulf of Mexico production topsides, Versabar engineered and designed a programmable logic control (PLC) deck jacking system.

The system used hydraulically and electronically synchronised rams, diesel hydraulic power units, a centralised PLC control and monitoring system, and custom engineered encapsulated leg sleeves.

Versabar’s patented deck raising system has also been successfully implemented in South East Asia to raise a multi-platform, bridge-linked complex in a simultaneous and synchronised process.

Custom manufactured hydraulic equipment

Versabar offers a wide range of custom engineered and fabricated hydraulic equipment, including:

- Hydraulic drum winches from 10t to 500t

- Hydraulic chain jacks from 400t to 1,500t

- Hydraulic traction winches up to 800t

- Level winds

- Diesel and electric-hydraulic power units

- PLC control systems

- Custom lift equipment using hydraulic cylinders

About Versabar

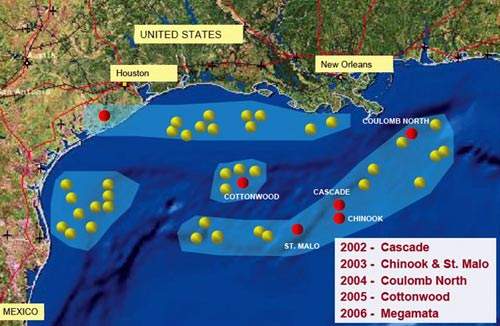

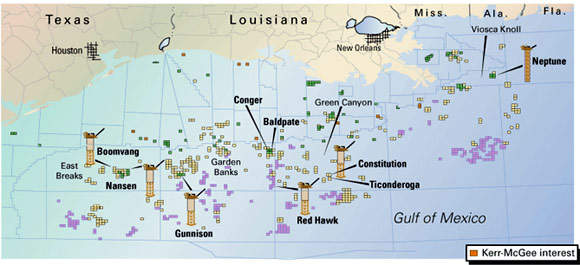

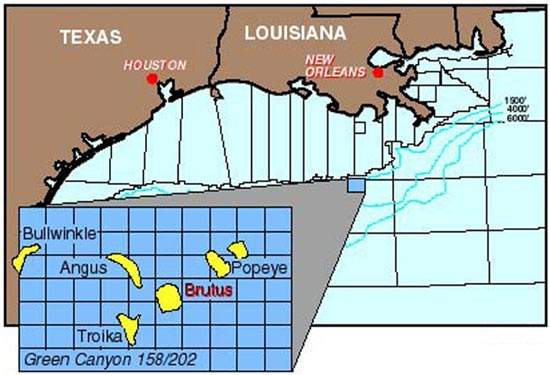

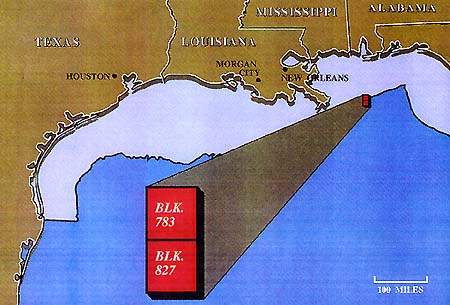

Versabar helps clients to manage risk while delivering solutions to increasingly complex projects, providing a full range of services from initial design to delivery. Based in Houston, Texas and New Orleans, Louisiana, US, the company supplies integrated solutions to customers worldwide.

With more than 30 years of experience in performing engineered lifting and pulling projects, Versabar has gained the trust and respect of major global offshore operators.

To view a list of Versabar’s completed projects, click here.