Gunnebo Lifting develops, manufactures and markets lifting systems of the highest quality and functionality. Each individual lifting component and chain link is tested 2.5 times their working load limit before delivery.

Gunnebo Lifting offer products that chain and components in grade ten and grade eight material, such as hooks, swivels and master links, as well as DNV shackles, lifting clamps, blocks and polyester products.

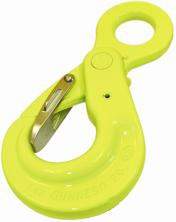

Gunnebo Lifting has developed products to meet the stringent requirements of the offshore oil & gas industry for many years. The working conditions are tough and products have to be able to sustain extreme conditions. Our double latch hook, BKD was developed with the aerospace industry as a role model; if one system fails another one is ready to save the situation. The extra latch on the BKD will retain the load in case an unintended opening of the first latch should occur.

DNV 2.7-1 approval

Gunnebo Lifting has a specific product range designed for offshore lifting, and is type approved by DNV to manufacture master links, hooks and shackles in accordance with DNV 2.7.1 specification.

The approval verifies that Gunnebo Lifting has a high consistent level of production stability in the entire process, from raw material to the finished product.

Shackles for extreme conditions

Gunnebo Lifting has specially-designed shackles for rough sea conditions; the Arctic Shackle. This shackle is type approved to DNV 2.7-1 offshore containers and meets the impact requirements of 42J at -40°C. The Arctic Shackle is a grade 8 shackle with all parts hot dip galvanised, including the safety bolt.

Offshore master links, shackles and hooks approved by DNV

When lifting offshore containers, the lifting sets (chain- or wire sling and shackles and master links) must be especially designed for use on containers. Gunnebo Lifting has a specific range designed for offshore lifting, including master links, shackles and hooks, approved by DNV to fulfil the requirements of DNV 2.7-1.

Gunnebo Lifting has for many years offered the industry the state-of-the-art top-quality lifting gear and is constantly working to make further improvements and innovations to increase the safety and efficiency of lifting.

Durable johnson blocks for tough applications

Gunnebo Lifting’s johnson blocks are famous for their durability and are well established in the industry. These blocks stand up to the toughest applications, whether in blistering sun or under icy blizzard conditions.

All johnson blocks are manufactured in our own factory in Tulsa, Oklahoma, US. This gives us the advantages of being able to control the quality on every step of the way, from raw material to finished product.

Flexible chain sling system for lifting

The all-inclusive chain sling system for coupling, shortening and lifting in grade ten is designed to improve your lifting actions and make it as quick and easy as possible. Some of the top features are:

- Less components – cost efficient

- Built in shortening function

- Light-weight for better ergonomics

GrabiQ has been designed to integrate multiple functions in each component. This means fewer components in each sling, but with the same, and better, function than with the old system. A good example of this is our FlexiLeg system, where one master link combined with one one-leg sling and two two-leg sling units, completely replaces four master links and ten legs of chain sling.

Gunnebo Lifting continuously innovates and launches quality products designed for the highest and best functionality and safety. Through the years we have developed many of the products that are today’s standard.

Gunnebo Lifting – Strength through innovation since 1764