Dynamic Load Monitoring specialises in the design, manufacture, repair and calibration of load cells and load monitoring equipment. Successfully supplying equipment for more than 20 years DLM have proved to be industry leaders in finding a solution to your load monitoring requirements.

Internationally known for an unprecedented high quality, reliable standard product range, DLM are also the world leaders in the design and manufacture of shear pin loadcells to the offshore industry. All DLM loadcells are manufactured in the UK and are underpinned by the ISO9001:2008 quality management system.

Our expert in house engineers are capable of designing loadcells and load monitoring for wide-ranging applications, working closely with clients from project inception through to completion and even installation.

DLM’s range of standard products includes standard tensile links, telemetry links, ILD’s, compressive cells and shear pin loadcells. Our standard product range is available on a short lead time and at very competitive prices. All DLM standard products are designed by engineers with practical experience within lifting gear and marine environments and manufactured using the highest quality materials. Further information can be found out about our standard product range below.

DLM’s standard tensile, telemetry links and in-link displays

In successful production for over 20 years, DLM offer two types of standard tensile link the original manufactured from high grade stainless-steel and the latest manufactured from light-weight aluminium.

Ideal for use in various tension load monitoring applications for industries worldwide, they combine a high level of performance with excellent value. Available in ranges from 1t to 100t as standard, higher loads are available to be designed upon request.

The telemetry link is ideal for applications where a signal cable is impractical either because of the environment or the distance from the loadcell to the display. It combines a high level of performance suitable for rugged environments worldwide, with a range in excess of 250m. Available in ranges from 5t to 100t as standard, higher loads are available to be designed upon request.

The DLM in-link display loadcell is ideal for applications where the object being weighed is within eye sight. The link houses a 4.5 digit display with four button operation. Its practical design, reliable instrumentation and robust construction have made this product an industry standard. It is available in ranges from 5t to 100t as standard and higher loads are available upon request.

Compressive and shear pin loadcells for the offshore industry

DLM’s range of standard compressive loadcell’s can be used independently or in combinations as part of weighing platforms etc. Available in ranges from 10t to 300t and manufactured using high grade stainless steel, these loadcells are particularly suited to rugged environments and the offshore industry amongst others. Other sized compressives can be designed upon request.

DLM are the world leaders in the design and manufacture of shear pin loadcells to the offshore, industry. We are able to supply shear pins with protection up to IP68 and can offer hermetic sealing and encapsulation against vibration and mechanical shock. Our in-house hydrostatic pressure chamber allows testing of these products up to 330 bar.

Shear pins are custom designed in a wide variety of sizes to suit clients exacting requirements. Applications include supplying as original equipment in subsea ploughs, installation communications cables in the ocean bed, installations in cranes, winches and also demanding environments such as single buoy moorings and FPSO’s.

Specialised load monitoring including running line monitors and saddlebacks

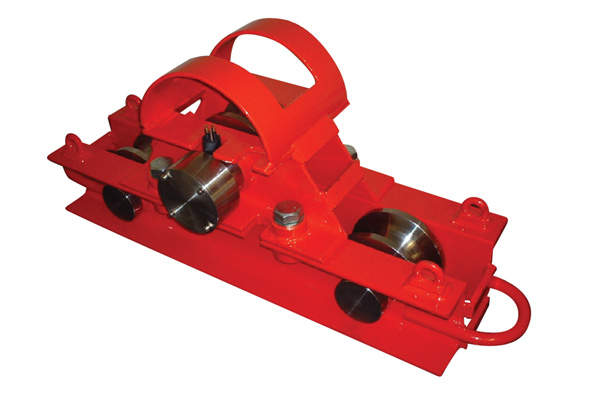

DLM offer two types of running line monitors, a three wheeled version and a five wheel option. The running line monitor measures tension on a rope or wire passing between its wheels. The axle of one of the wheels is a shear pin loadcell, which supplies line tension data via a 4mA to 20mA amplifier. Another of the wheels includes a rotary encoder, whose push pull quadrature output enables the speed and distance of the cables pay-out and return to be monitored.

The DLM Saddleback is a line tension monitor suited for more delicate cables, including telecommunication cables. The line tension is measured by the cable passing over the chute and deflecting the loadcell mounted beneath. As with the running line monitors, the speed or distance of the cable pay out can be measured by the roller arm incorporated within the saddleback.

In addition DLM are also able to offer mounting gear for running line monitors and saddlebacks such as cradles with goal posts, wear plates and fleeting gear.

DLM running line monitors and saddlebacks are usually supplied with rugged master and slave displays suitable for installation in ships winch rooms and the ships bridge.

The DLM cable counter is a widely used and highly effective cable measuring device. Frequently used on cable laying vessels it combines durable, robust design with high reliability. The counter is fitted with a measuring wheel which supplies data via the sealed rotary quadrature shaft encoder. The counter can be supplied with a DLM display cabinet or as a stand alone unit supplying just the quadrature encoder output for integration into clients existing systems.