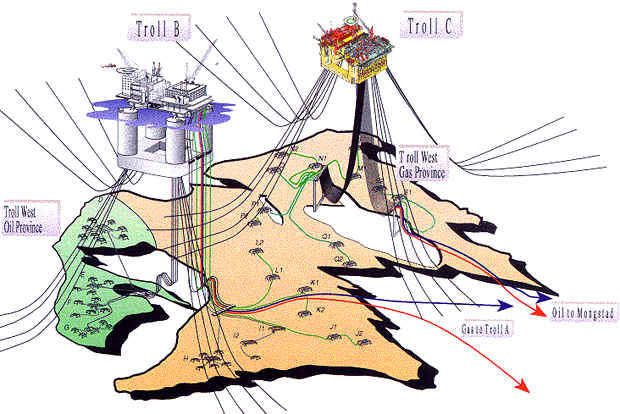

Alimak has been supplying rack and pinion elevators and lifts to the offshore industry since 1974 when it installed its first unit on an Aker H-3 design semi-submersible. The benefits of installing elevators from Alimak are recognized worldwide by oil & gas companies for platforms, semi-submersible rigs and drillships.

Alimak offers both rack and pinion and traction elevators. They are mostly installed on derricks, in hull columns, living quarters and outside platform modules and are built for harsh environments. The elevators complement potentially hazardous stairways and ladderways to provide convenient access to pump and machine rooms and other process-critical areas.

Advantages of Alimak rack and pinion elevators

- Made for tough environments

- Simple and cost-efficient installation

- No separate machine room

- No pit or lift-shaft needed

- Easy to install to almost any structure

- Small footprint

- Can be installed on inclined and curved surfaces

- Indoor or outdoor installation

- Durable and easy to service and maintain

- Explosion protected lifts for hazardous areas

- Operation not affected by rolls, pitches or heaves

- Easy to retrofit to existing structures

Derrick Elevators

Rack & Pinion type

The Alimak derrick elevator fits on all types of derricks for platforms, jack-ups, semi-submersibles, and drillships.

The typical Alimak derrick elevator is often installed on the outside of the derrick structure and has between 3–5 landings and a lifting height ranging between 55 meters to 60 meters. The elevator gives access for inspection and maintenance of the drilling equipment and is a vital component to ensure safe and convenient access.

TECHNICAL SPECIFICATIONS

(Common data for a typical derrick elevator)

Elevator type: Rack & pinion

Elevator model: ALIMAK SE-Ex

Ex class: ATEX or NEC

Payload capacity: 500 kg

Lifting height: Up to 60 m

Car size: 910 x 1,300 x 2,170 mm (W x L x H)

Control system: Collective control

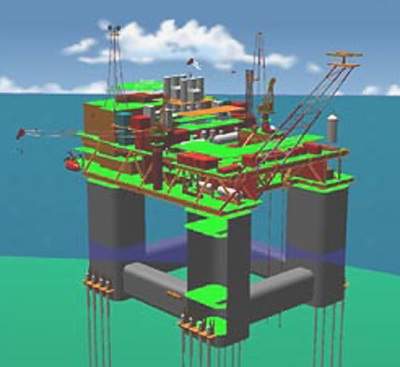

Hull Column Elevators

Rack & Pinion type

The Alimak column elevator fits on all types of hull columns for platforms and semi-submersibles.

The typical Alimak column elevator is installed inside the column structure and has between 4–6 landings and a lifting height ranging between 10 meters to 30 meters. The elevator gives access for inspection and maintenance of pumps and machine rooms and is a vital component to ensure safe and convenient access.

TECHNICAL SPECIFICATIONS

(Common data for a typical column elevator)

Elevator type: Rack & pinion

Elevator model: ALIMAK SE

Ex class: Safe area

Payload capacity: 1,200-1,500 kg

Lifting height: Up to 30 m

Car size (internal): 1,300 x 2,470 x 2,170 mm (W x L x H)

Control system: Collective control

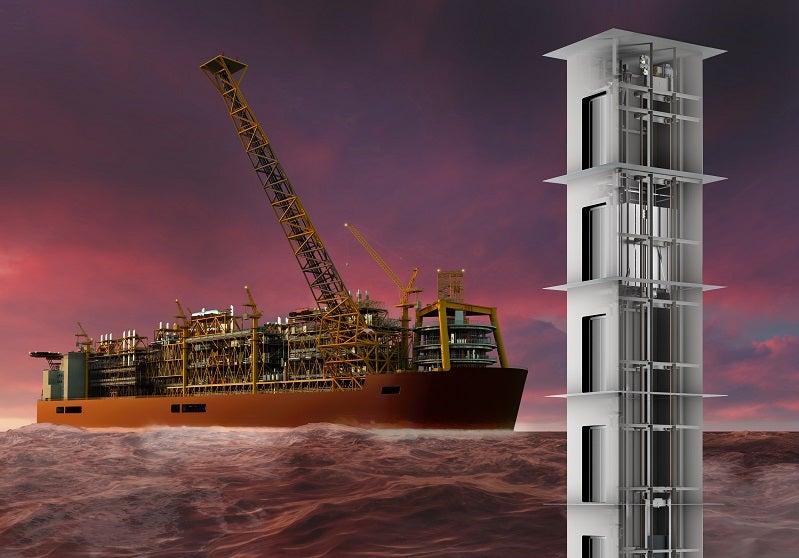

Living Quarter Elevators

Traction type

The ALIMAK OS elevator fits on all types of living quarters for platforms, jackups, semi-submersibles, drillships and offshore vessels.

The typical ALIMAK OS elevator is often installed on the inside of the living quarter module but can also be installed outside with a watertight shaft.

TECHNICAL SPECIFICATIONS

(Common data for a typical living quarter elevator)

Elevator type: Traction

Elevator model: ALIMAK OS

Ex class: Safe area

Payload capacity: 630-2,500 kg

Lifting height: Up to 80 m

Car width (internal): 1,200-1,400 mm

Car length (internal): 2,200-2,400 mm

Car height (internal): 2,200-2,400 mm

Control system: Collective control

Cargo Elevators

Rack & Pinion and Traction types

Rack and pinion and traction elevators from Alimak Hek can be customized for the most varying purposes on all types of offshore applications. The modular elevator series ensures your vertical access requirements are fulfilled in even the toughest working conditions.

The cargo elevator series are designed to handle materials weighing up to 15,000 kilograms when required. It ensures easy transportation of various heavy-duty goods and consignments between different levels.

Loading and unloading has never been easier with crane or forklift, since on some models the elevator floor will level with top most landing without permanent equipment above.

TECHNICAL SPECIFICATIONS

Elevator types: Rack & pinion and Traction

Elevator models: ALIMAK SE-H & SE-H Ex, ALIMAK FM & FM-Ex, ALIMAK OS & ALIMAK OS-Ex

Ex class: Safe area, ATEX or NEC

Payload capacity: Up to 15,000kg

Lifting height: Up to 50m

Control system: Collective control

Retrofits

Alimak elevators can easily be installed on any structure and are ideal for retrofitting on existing oil-rigs that are undergoing upgrading, or retrofitted in other hazardous industrial environments. Alimak has actively been involved in a wide range of modernisation projects.

ISO 9001 quality

Alimak is third party certified against ISO 9001: 2000, ISO 14001 and OHSAS 18001. In addition, the company also receive specific project-to-project third party certification by independent bodies such as Lloyds, DNV and ABS.

Alimak engineers have long and vast experience from projects with high demands and are able to handle special project through all stages. They are trained and organised to provide project plans and risk analyses, carry through approval and inspection procedures and deliver correct, complete documentation on time.

Worldwide organisation

Alimak is the global market leader and pioneer in designing, developing, manufacturing and servicing industrial rack and pinion vertical access solutions. The company provides high-quality rack and pinion and traction elevators, hoists and platforms primarily for the industrial and construction sectors. Alimak has a well-established global sales, services and distribution platform across more than 90 countries with strong market presence. The company has a large global installed base of over 23,000 units which provides unique know-how of all industrial application areas. Alimak was founded in 1948, is headquartered in Stockholm, Sweden, and employs over 1,200 people across the world.