Zicom Equipment (ZEPL) specialises in oil and gas metering and regulation systems for custody transfer application and terminal automation systems.

ZEPL is a wholly owned subsidiary of Zicom Group, an Australian stock exchange-listed company with its corporate office in Brisbane, Australia, and its operations headquarters in Singapore, where ZEPL is based.

Natural gas and liquid metering and regulation stations

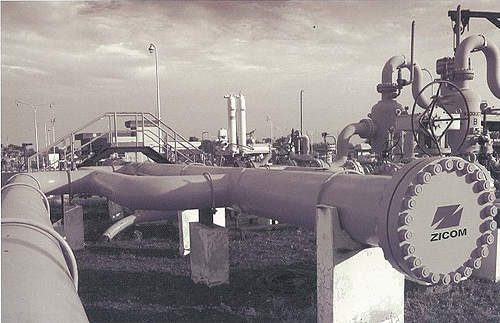

Zicom designs, engineers and fabricates natural gas and liquid metering and regulating stations / skids, customised to the customer’s specification and industry standard.

Natural gas metering comprises measuring for custody transfer and/or quality control. The quantity of gas can be measured using orifice metering, vortex metering, turbine metering, ultrasonic metering, etc. With the flow computers, the measurements can be converted to normal or standard cubic meters or feeds per hour of day.

For natural gas custody transfer application, it is generally based on the quantity of energy delivered. On-line gas chromatography is employed for the calculation of heating value.

Oil and gas metering system applications

In gas applications, pressure reduction and regulation is needed. Gas distribution systems start in the pipeline with a pressure that is above 1,000psig and ends up at the commercial or domestic consumer’s end as low as 0.54psig. Metering and regulating skids / stations are utilised by transmission and distribution companies to regulate and meter the gas.

Critical to the performance of any metering installation is the computer control system. To ensure proper management of this important hardware and software interface, Zicom’s custom or standard panels integrated with the metering systems perform seamlessly.

Zicom metering systems are designed and built for:

- Fiscal metering

- Custody transfer

- Allocation metering

- Pipeline integrity

- Power utilities

- Auxiliary metering

- Pressure reduction systems

- On-line analytical systems

The systems meet a number of international measurement requirements such as ATEX, PTB, DIN, BSi, NIST, CE, NACE, ANSI, IEC, API, NPD, AGA, NMi, DTI, OIML, UL and ISO.

Indirect water bath heaters

Zicom manufactures custom-designed indirect water bath heaters as per individual applications and requirements, to ensure fluid is reliably and safely heated to the necessary temperature to meet downstream process requirements.

The heater consists of three basic elements; the fire tube, the heater shell, and the process coil. The fire tube is designed to transfer heat, released by the combustion of fuel, into the water bath. The shell is designed to contain the heat transfer media. The process coil is designed to safely contain the process fluid and transfer the required heat from the water bath into the process stream.

Indirect water bath heaters are commonly used in applications requiring a maximum bath temperature of 203°F (95°C) and a normal bath temperature of 158°F to 194°F (70°C to 90°C). As a minimum, Zicom water bath heaters are equipped with the following equipment and shutdowns:

- Flame arrestor on any combustion air intake

- Stack of suitable height to ensure adequate draft for the burner system

- Level detection to prevent a low-level hazard

- High-temperature shutdown

- Burner management system

The bath heaters are also equipped with the following controls: fuel gas pressure switch (high), fuel gas pressure switch (low) and stack high-temperature shutdown.

Natural gas transmission pipelines often contain liquids that can interfere with the proper operation of the pipeline and related equipment such as compressors, regulators, filters, meters and valves. The liquid containments normally include hydrocarbon condensations, lubrication oils, produced water, and chemicals used in production treatment, compression or dehydration of gas.

Filters and separators for water and contaminate removal

Zicom designs and manufactures a wide range of filters and separators to remove water and contaminants from hydrocarbon gases and liquids. Our separators provide unmatched liquid and solids removal and require no maintenance to meet customers’ diverse specifications. Whenever your application requires removal of liquids and solids that are smaller than 3µm, Zicom is your solution.

Vertical separators

Vertical separators are well-suited for handling large liquid slugs, solids and surging flow conditions. In addition, vertical separators require less floor space. In standard vertical up-flow designs, the gas volume is limited due to re-entrainment because of the counter-current flow of gas (up) and liquid (down). Vertical units, equipped with specifically designed vane mist extractors, eliminate re-entrainment and have an increased gas capacity.

Applications include the removal of water and containments from many hydrocarbon gases such as natural gas, propane, butane and methane.