Yokogawa is a world leader in the supply of control and instrumentation systems to the offshore and onshore oil and gas industries. Key product sectors include Distributed Control Systems (DCS), safety systems, alarm management, data acquisition and field instruments. Yokogawa provides a wide range of oil and gas production solutions that are designed for maximum reliability while keeping personnel costs and business risk to a minimum and optimising the management of remote facilities.

DISTRIBUTED CONTROL SYSTEMS (DCS)

The CENTUM CS 3000 integrated production control system is Yokogawa’s flagship offering in the area of Distributed Control Systems (DCS). More than 18,500 systems have been delivered around the world for use in petroleum, natural gas, chemical, and other types of process plants. Yokogawa continues to introduce new functions with functional continuity, and realises an open architecture with high reliability. The latest version offers enhanced gateway functions to aid integration of the operation and monitoring of other vendors’ systems in an overall plant.

SAFETY MANAGEMENT SYSTEMS

ProSafe-RS is the first truly integrated safety controller to achieve absolute integrity between distributed control systems and Safety Instrumented Systems (SIS). ProSafe-RS complies with the IEC61508 international safety standard and is approved for applications up to Safety Integrity Level (SIL) three.

Major target applications are emergency shutdown systems and fire protection systems in plants in the oil, natural gas, petrochemical, and other process industries.

ALARM MANAGEMENT SYSTEMS

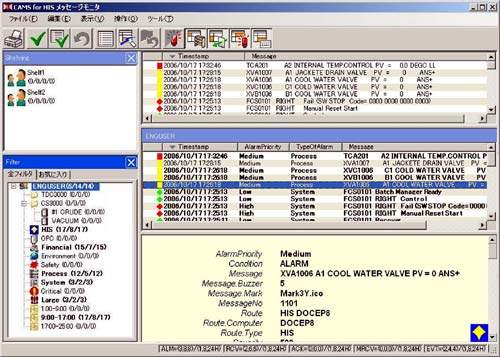

Yokogawa has developed the world’s first Consolidated Alarm Management Software Package for Human Interface Station (CAMS for HIS). This offers a real-time alarm management function that works in harmony with a distributed control system and provides multiple approaches to alarm management.

This system addresses the challenges presented by the fact that operators are being asked to respond to a greater number and variety of alarm and event messages as plants increase in size, control rooms become more integrated, and processes grow more complex. The new system will relieve operators from ‘alarm flooding’ and ensure that important alarms are not overlooked.

DATA ACQUISITION

Yokogawa supplies a wide range of controllers, recorders and data-acquisition systems, supported by data acquisition and monitoring software. These units are fitted with powerful communications and web server capabilities, allowing their integration into complete monitoring and control networks.

Yokogawa’s DAQSTATION family of data-acquisition stations, for example, offer extended multi-channel acquisition at high sampling speeds and large internal memory capacity. Enhanced network functions include powerful web facilities plus Modbus/TCP and SNTP/DHCP communications, while the inclusion of a USB interface and the AddDataBrowser function from Yokogawa’s DAQWORX software suite provides flexible browsing capabilities.

FIELD INSTRUMENTS

The range of field instruments produced by Yokogawa includes pressure, temperature and level transmitters, flowmeters, valve positioners and controllers. Many of these instruments have FOUNDATION Fieldbus communications, and several meet the latest standards for safety instrumented systems.

Typical of these new instruments is the Yokogawa EJX910A multivariable pressure/flow transmitter, which provides measurement of six variables including differential pressure, static pressure and a range of temperatures. This unit is available with FOUNDATION Fieldbus capability along with a flow configuration tool using FDT/DTM technology based software.

VIGILANTPLANT

VigilantPlant is a concept that brings together the company’s products and services to create an environment where plant operators and other personnel are watchful and attentive, well-informed and ready to take action.

Through solutions and services designed to help plant personnel ‘see clearly’, ‘know in advance’, and ‘act with agility’, the VigilantPlant philosophy eliminates unplanned downtime, improves asset utilisation, and allows businesses to adapt to shifting market conditions and customer demands quickly and efficiently. Concepts such as asset excellence and plant resource management combine with control and monitoring system to provide a clear path to operational excellence.