The Permasense wireless Integrity monitoring system uses state-of-the-art technology to continuously monitor pipework wall thickness in real-time. The system is employed in onshore and offshore facilities, as well as in both upstream and downstream sectors in the oil and gas industry.

Now implemented worldwide, Permasense pioneered this technology to better inform oil and gas producers and processors on the integrity and erosion or corrosion rates of their pipes and pipework in service.

Battery-operated corrosion and erosion detection sensors

Permasense sensors are designed to be permanently affixed to any area of interest, for example, where high erosion or corrosion rates are expected or in difficult to access locations. They are battery-operated, providing maintenance-free operation for up to ten years.

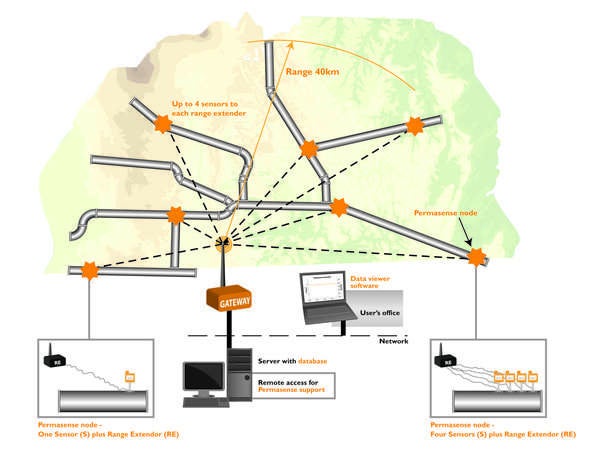

The sensors use a wireless mesh network for transmitting measurements to the desks of integrity personnel, whether they are offshore or onshore, and are designed to work in harsh environments and remote locations, such as offshore unmanned platforms.

Real-time erosion and corrosion readings

The insight gained from a real-time understanding of the integrity of the interior of pipework provides a competitive edge over facilities that don’t have this information.

Permasense systems give an accurate reading that allows plant managers to know if they need to mitigate corrosion or erosion attack or are able to operate more aggressively, for example by producing at higher rates or extending integrity operating windows.

Cost-effective pipe corrosion detection solutions

In remote, unmanned platforms, detecting and monitoring corrosion and erosion levels can be an expensive operation.

By using Permasense sensors to monitor corrosion and erosion of pipework, platform engineers have a cost-effective method to get a better understanding of their assets’ integrity in service. Pipework maintenance activities can be better informed and therefore more effective, improving availability and reducing unplanned downtime.

About Permasense

In the oil and gas industry, it is all about clients getting the most from their resources while minimising costs. Permasense provides operators with the knowledge they need to make better informed decisions that extend far beyond traditional asset integrity management decisions.

Oil and gas producers need to leverage their assets as far as possible, increasing production rates whilst minimising downtime. Corrosion and erosion cause continuous problems and understanding how they are impacting facility infrastructure can mean the difference between operating efficiently and unplanned downtime.

The Permasense system is fast becoming the cornerstone of pipework integrity management in oil and gas facilities, delivering the quality and frequency of information to enable significantly improved decision making during operation to enhance the profitability of its clients’ operations.